Sand blasting device for wind blade surface and sand blasting method thereof

A wind blade and surface sandblasting technology, which is applied to used abrasive treatment devices, abrasive jetting machine tools, abrasives, etc., can solve problems such as difficulty in selecting sandblasting materials, difficulty in designing sandblasting systems, and uncontrollable polishing quality. , to achieve the effect of good sandblasting treatment, saving manpower and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

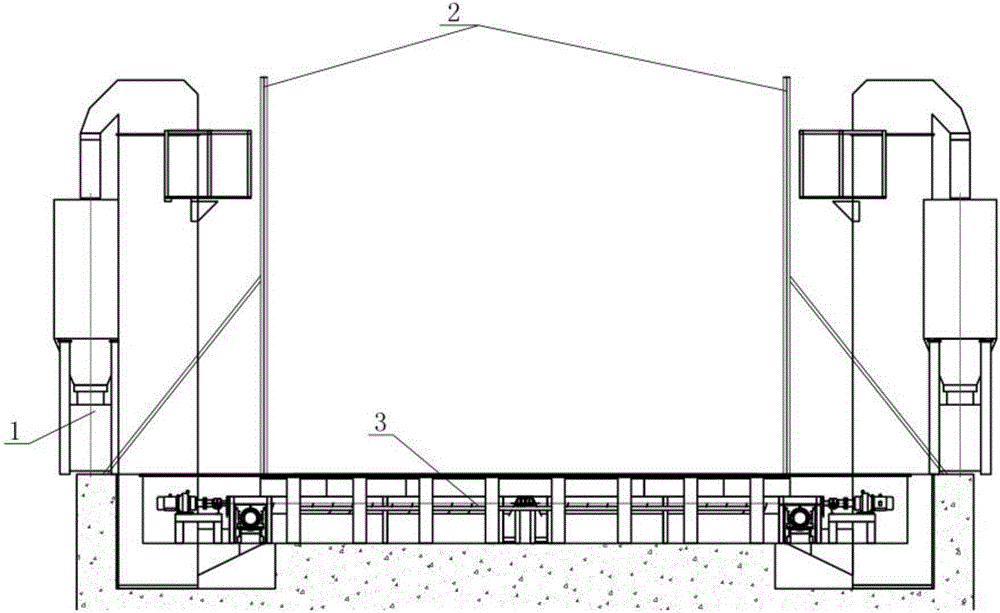

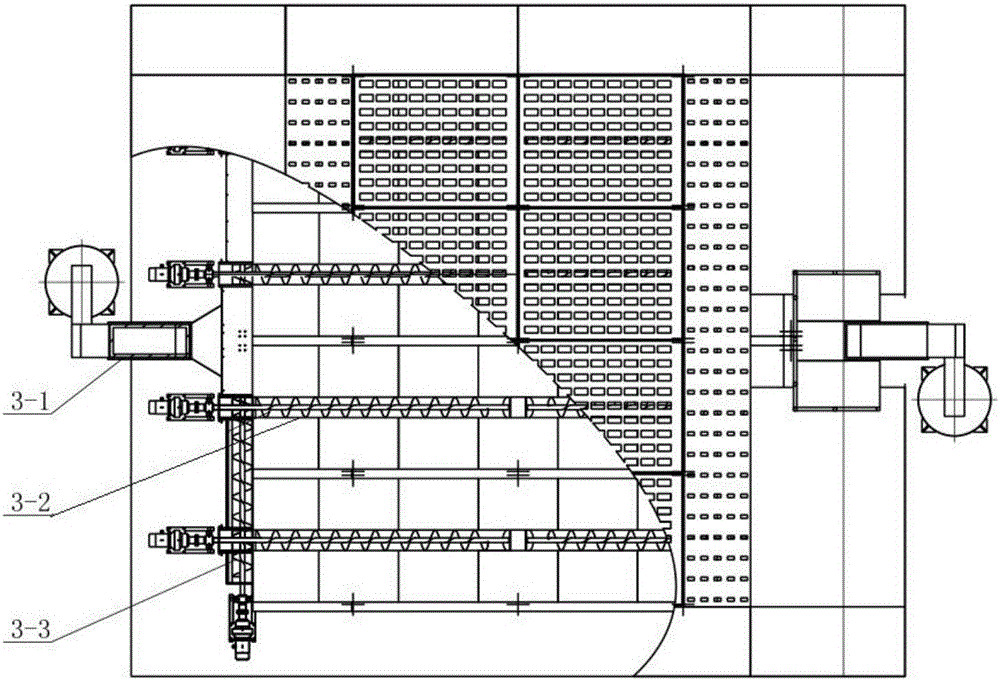

[0032] Such as figure 1 and figure 2 Shown, a kind of wind blade surface blasting treatment device, it comprises the following steps:

[0033] A sandblasting treatment device for the surface of a wind blade, which includes two symmetrical sandblasting mechanisms 1, a dust removal mechanism 2 installed between the two symmetrical sandblasting mechanisms 1, and installed at the bottom of the middle area of the two symmetrical sandblasting mechanisms 1 The sand material recovery mechanism 3 is installed on the blade walking mechanism at the front and rear sides of the sand material recovery mechanism 3;

[0034] The sandblasting mechanism 1 comprises a sandblasting machine and a storage tank connected with the sandblasting machine;

[0035] Described dedusting mechanism 2 comprises dedusting fan, the filter system (pulse bag type dedusting system) that links to each other with dedusting fan;

[0036] The nozzle in the sandblasting machine blasts the surface of the wind blad...

Embodiment 2

[0044] Such as figure 1 and figure 2 Shown, a kind of wind blade surface blasting treatment method, it comprises the following steps:

[0045] Step a, hoisting the wind blades onto the transfer trolley, pulling the transfer trolley through the hoist, and transporting the wind blades to the middle of the two symmetrical sandblasting mechanisms 1;

[0046] Step b, start the sandblasting mechanism 1, so that the resin sand or quartz sand spray material is injected into the sandblasting machine from the storage tank, and sandblast the surface of the wind blade;

[0047] Step c, during the sandblasting process, the dust removal mechanism 2 starts to work, and the dust generated by sandblasting is discharged into the filter system by the dust removal fan, and oscillates under the action of the pulse dust collector of the filter system to achieve the purpose of removing dust;

[0048] Step d, resin sand or quartz sand spraying is transported to the bucket elevator 3-1 through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Spiral diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com