Deep hole blasting construction method for high slope under complicated environment

A construction method and complex environment technology, applied in the field of engineering blasting and rock mechanics, can solve the problems of insufficient control of blasting vibration and blasting scatter, unfavorable, economic losses, etc., to reduce the hazards of blasting vibration and blasting flying rocks, and facilitate operation , Reduce the effect of secondary disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific examples.

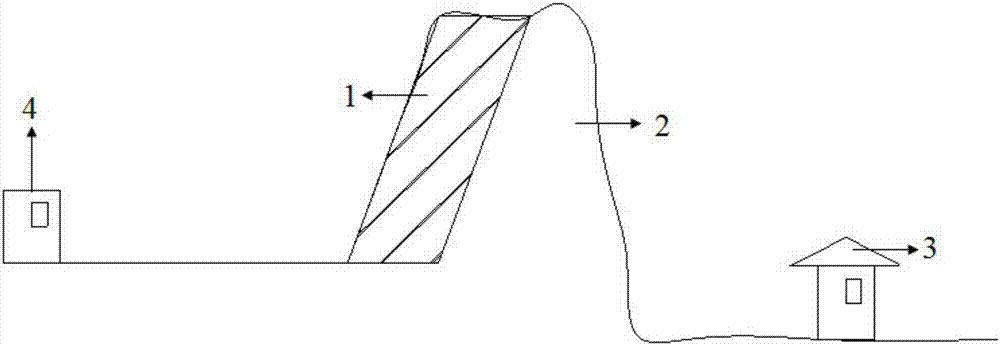

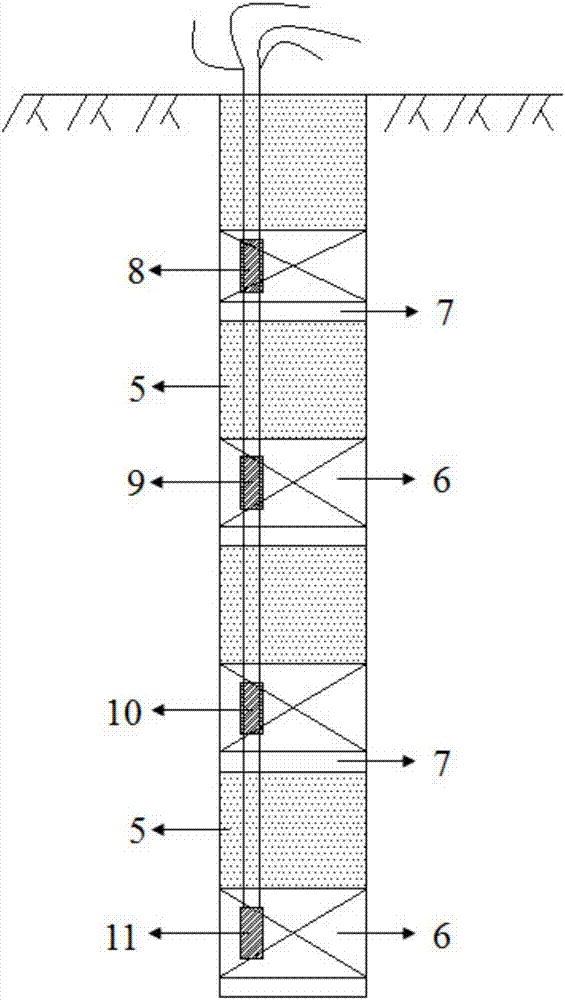

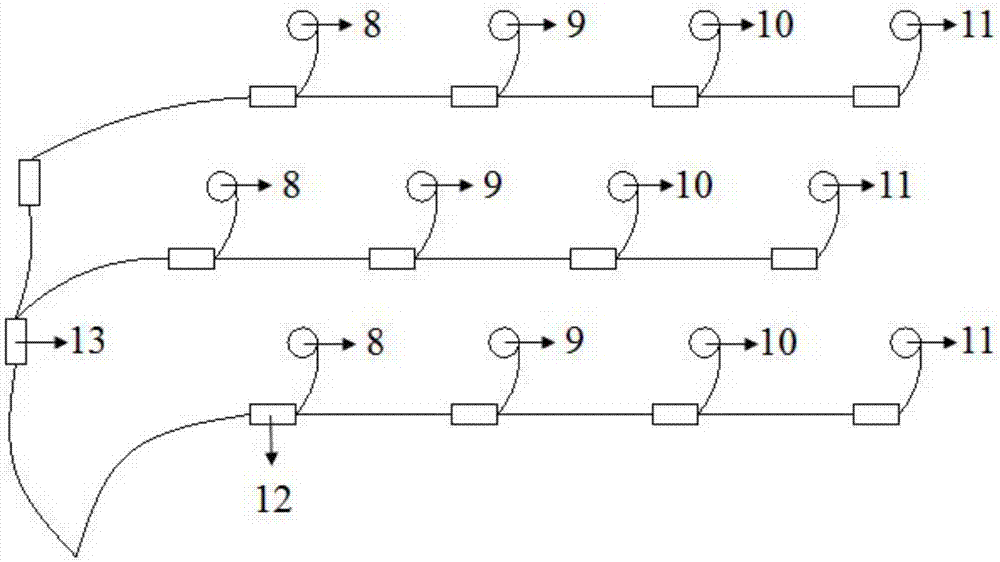

[0041] like figure 1 As shown, the slope height of a certain slope blasting project is 15-22m, the blasting width is 8-15m, and the final slope angle is 70°, which can be divided into excavation area 1 and retained rock mass 2. The slope is limestone rock, moderately weathered in the upper part and weakly weathered in the lower part, with massive structure and well-developed bedding, belonging to medium hard rock. In the high slope explosion area, many houses 3 on the slopes along the line are brick-concrete structures with a long history. The foundation elevation of house 3 is lower than the bottom elevation of the blasting excavation, and it is integrated with the mountain, and the nearest distance to the blasting point is only 25m. At the same time, about 50m in the direction of the resistance line, there are four factory buildings 4 under construction, which are reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com