Intelligent logistics loading and unloading system for pallet-free transportation

A technology of intelligent logistics and loading and unloading system, which is applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., and can solve the problem of inability to realize palletless cargo transportation, large changes in trucks and platforms, and small compatibility of trucks and platforms and other issues, to avoid high cost problems, improve transportation safety, and save transportation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

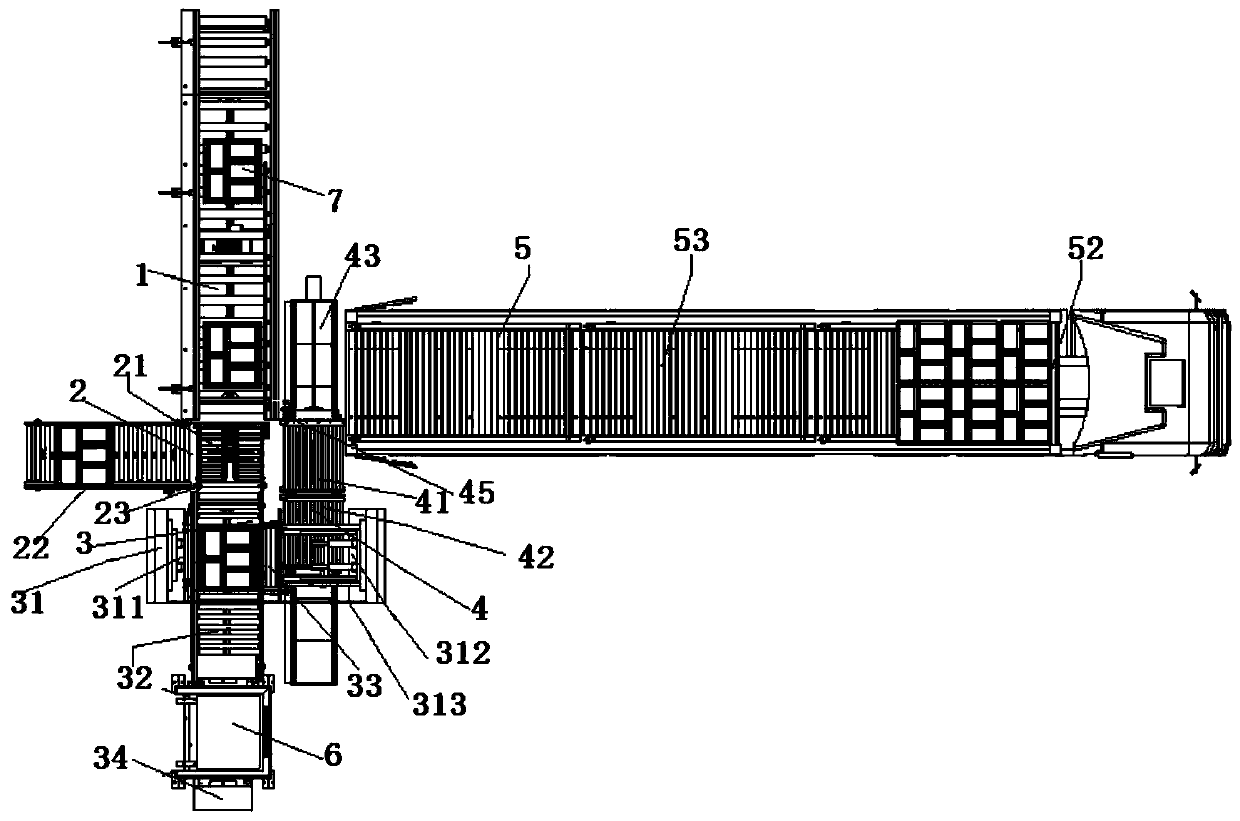

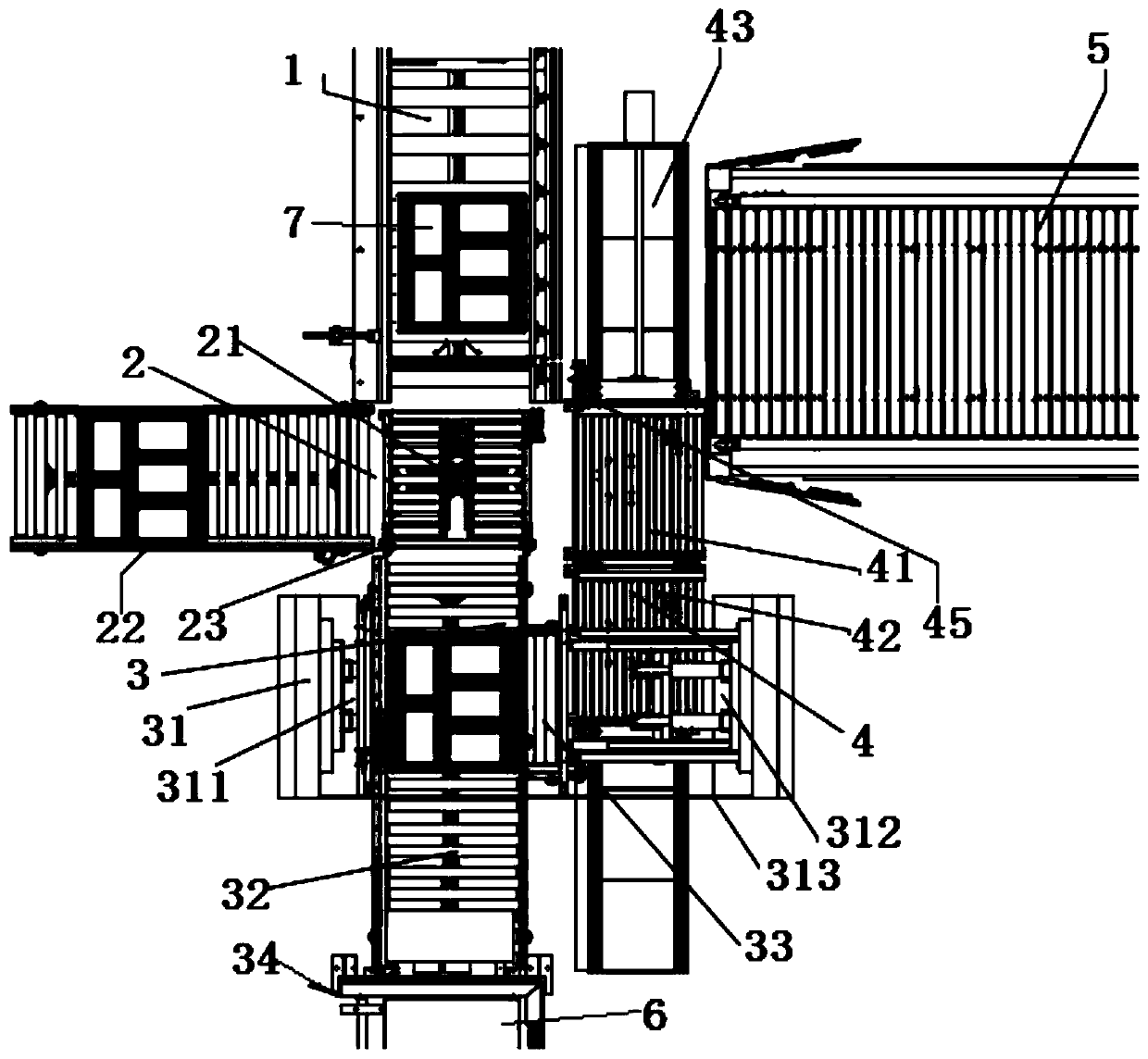

[0029] Such as figure 1 , 2 As shown, the intelligent logistics loading and unloading system for palletless transportation in this embodiment includes a vehicle-mounted conveying mechanism and a loading and unloading platform. The vehicle-mounted conveying mechanism is installed on the floor of the carriage, and the loading and unloading platform is installed on the platform or the ground.

[0030] The loading and unloading platform includes a conveyor 1, a stacking visual inspection device 2, a pallet loading and unloading device 3, and a positioning and moving horizontal track device 4.

[0031] Pile-type visual detection device 2 comprises a pile-type detection conveyor 21, a pile-type conveyor 22 to be sorted out, a pile-type visual detection and control mechanism-23, and the pile-type detection conveyor 21 is a conveyor that can rotate 90 degrees, and one end thereof is connected to Conveyor 1 is docked smoothly.

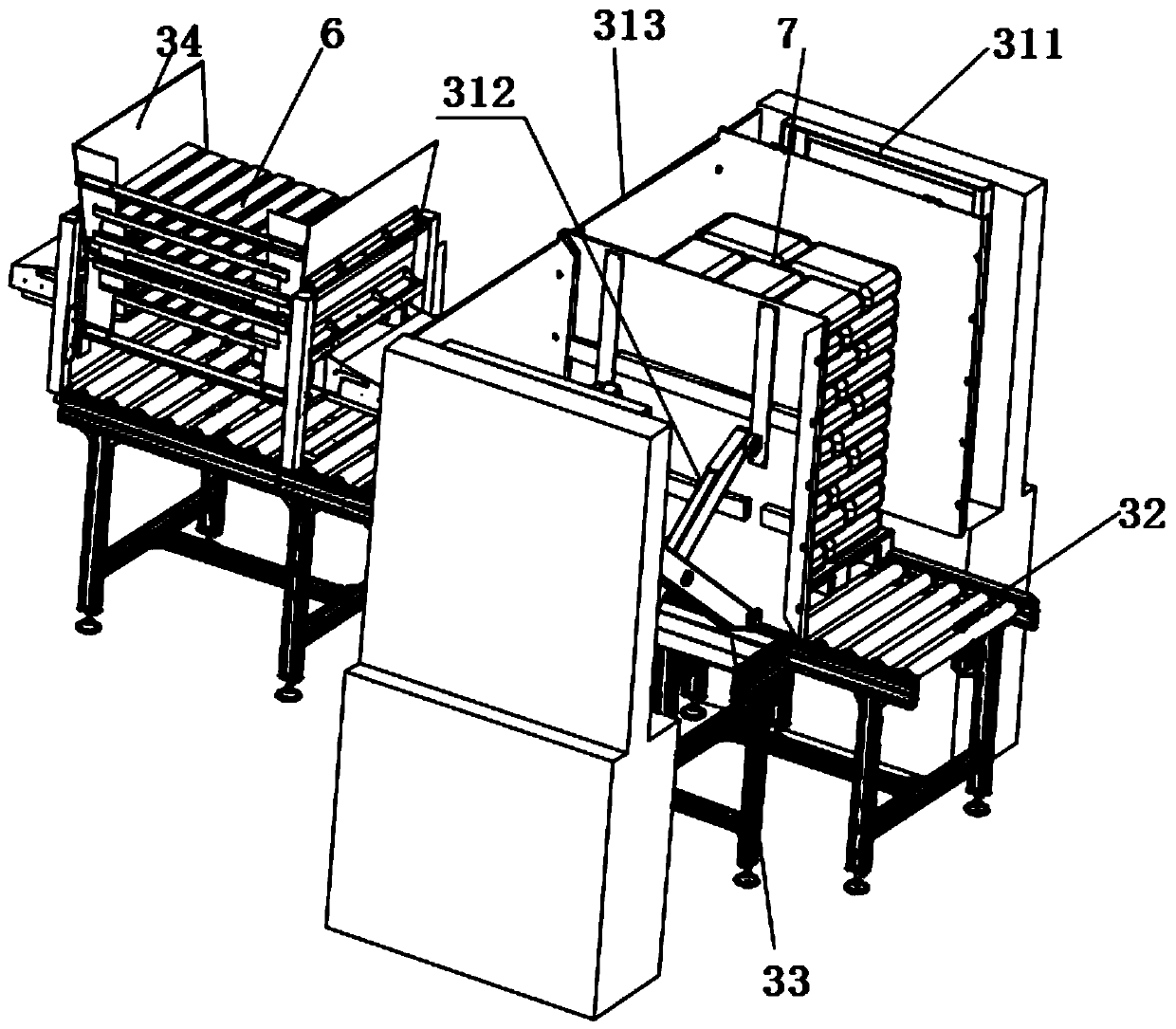

[0032] Such as image 3 As shown, the pallet loading a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com