IC link rod manufacture process

A technology for internal combustion engines and connecting rods, which is applied to connecting rods, mechanical equipment, shafts and bearings, etc., can solve the problems that can only be processed in sections, and the connecting rod body and connecting rod cover cannot be forged at the same time, so as to simplify the processing. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

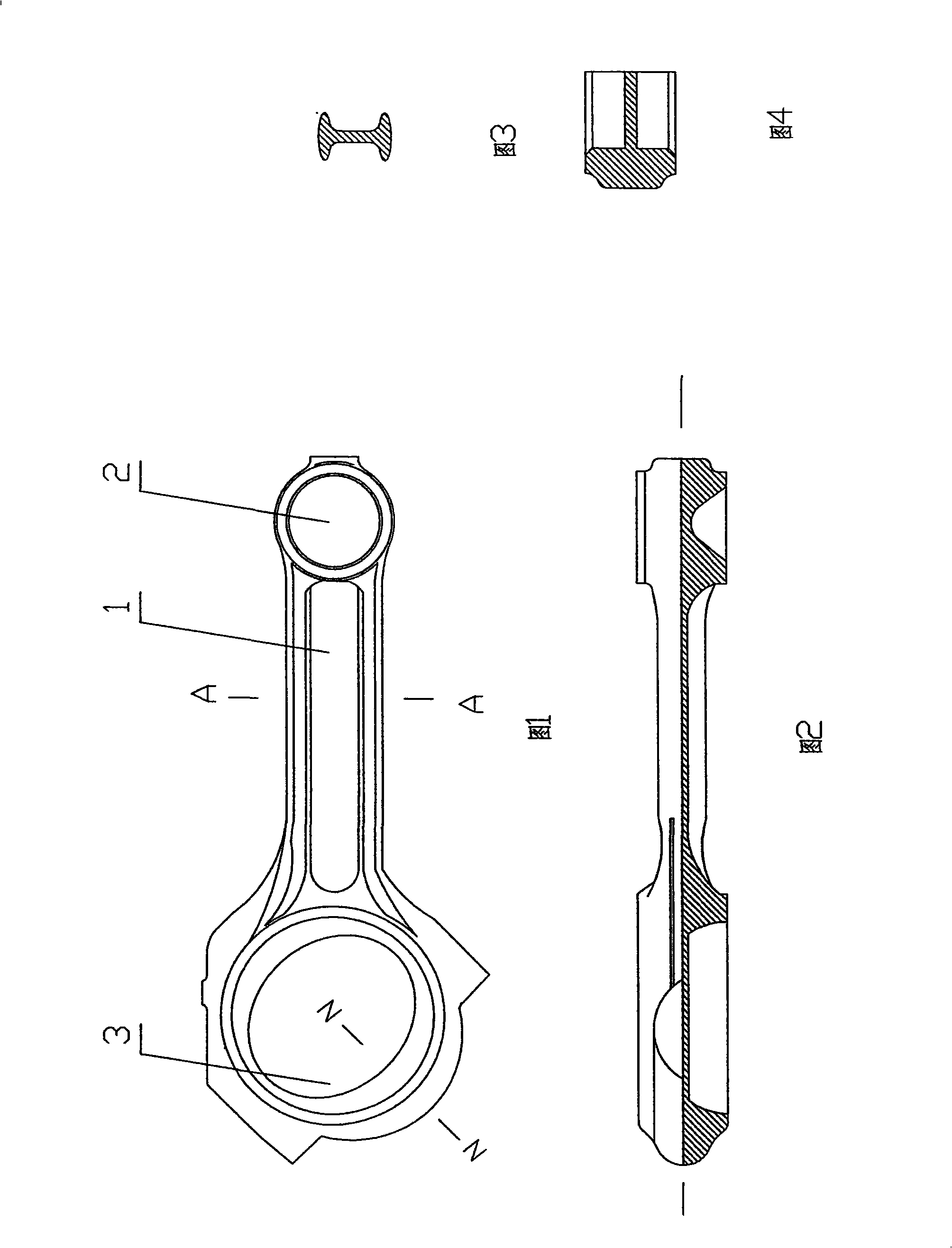

[0024] Technology of Connecting Rod for S195 Diesel Engine

[0025] Using the traditional die forging process to forge a connecting rod blank 1 with large and small heads through the forging die, and carry out shot blasting, flaw detection and phosphating treatment on the connecting rod blank; rough mill two planes, and process piston pin installation at the small head Hole, orifice chamfering 1×45°; take the center of the piston pin installation hole as the positioning reference involved in the subsequent processing procedure, cut along the elliptical minor axis of the overall blank big head pit, and form the connecting rod body blank and the connecting rod cover plate blank , and when forming the blank of the connecting rod body and the blank of the connecting rod cover plate, it is necessary to print the pairing marks, and then mill their cutting joint surfaces; merge the joint surfaces, and simultaneously drill the installation butt holes of the connecting rod body and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com