Robot welding equipment for crawler welding

A robot welding and welding robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high welding labor intensity, troublesome welding work, and low welding efficiency, and achieve high welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

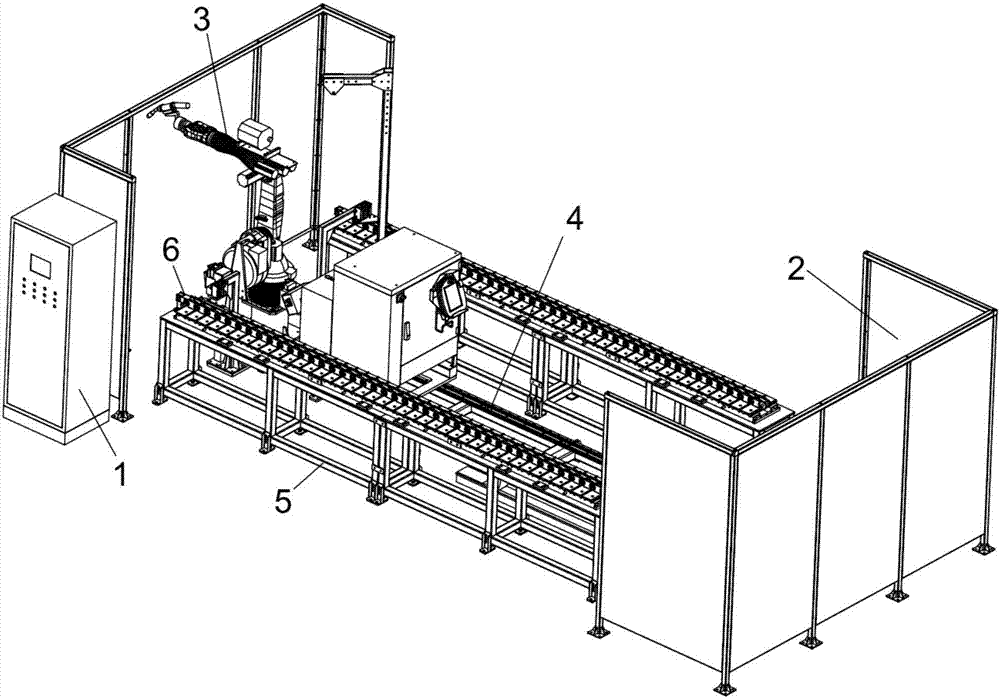

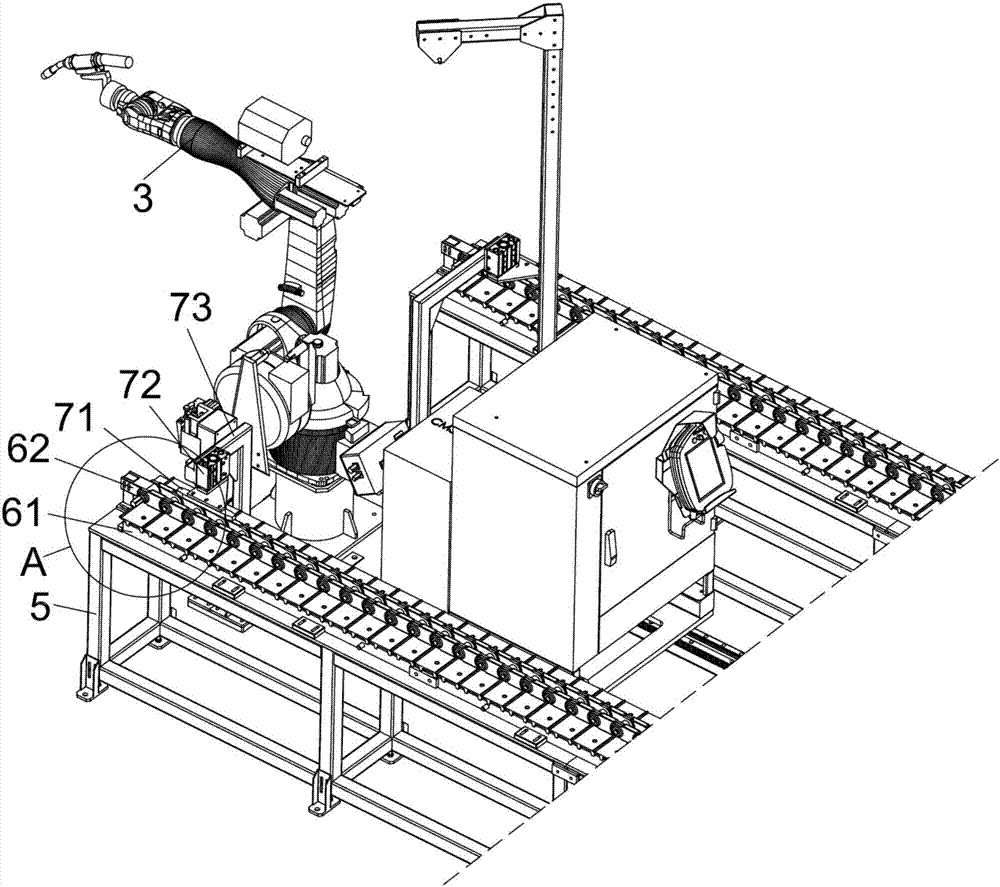

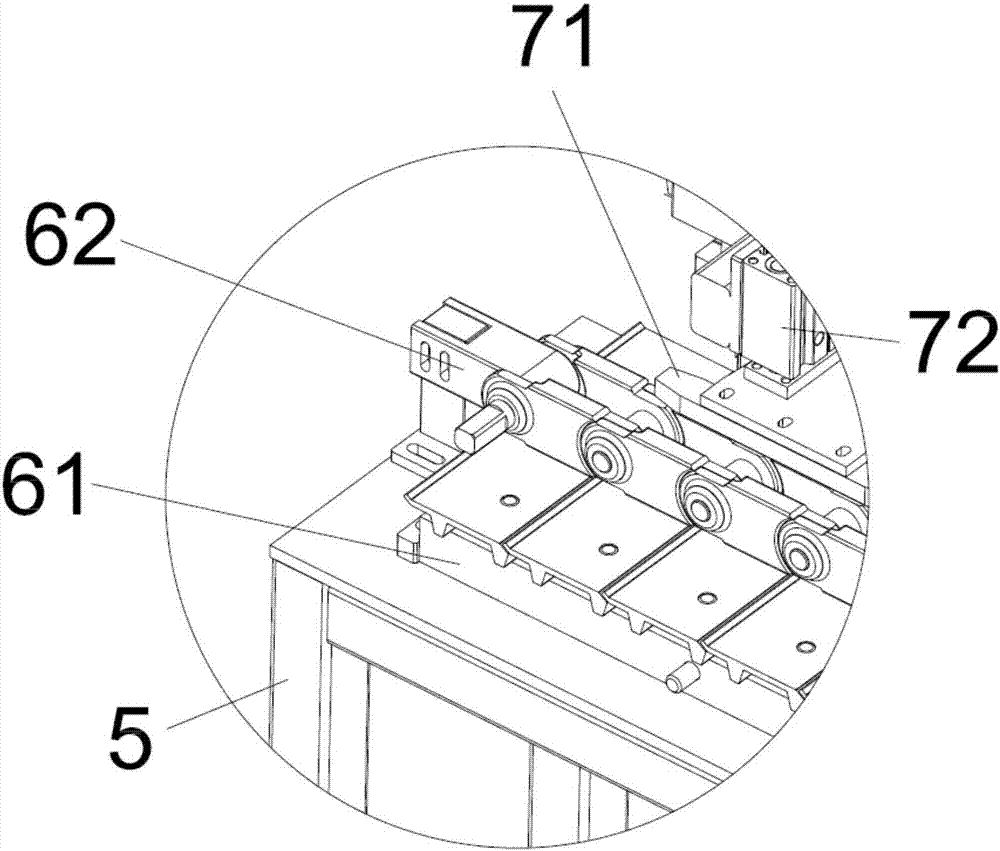

[0020] refer to Figure 1-4 , a kind of robot welding equipment that is used for track welding of the present invention comprises robot moving mechanism 4, and welding robot 3 is arranged on the robot moving mechanism 4, and the both sides of robot moving mechanism 4 are respectively provided with the tooling platform 45 that is used to place crawler belt, The tooling platform 45 is provided with a positioning tooling 6 for positioning the track.

[0021] The robot moving mechanism 4 comprises a base 41, a pair of linear guide rails 45 and a spur rack 44 are laid on the base 41, a slide table 42 that can slide along the linear guide rail 45 is set on the linear guide rail 45, and a drive motor is provided on the slide table 42 to drive The output shaft end of the motor is provided with a driving gear 43 meshing with a spur rack 44 , and the welding robot 3 is arranged on the slide table 42 . The drive gear 43 is driven by the drive motor to rotate, and when the drive gear 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com