Workbench

A workbench and workhead technology, which is applied in the direction of mitering work devices, manufacturing tools, metal processing, etc., can solve the problems of troublesome operation, high cost, complicated structure of the workbench, etc., and achieves convenient operation, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

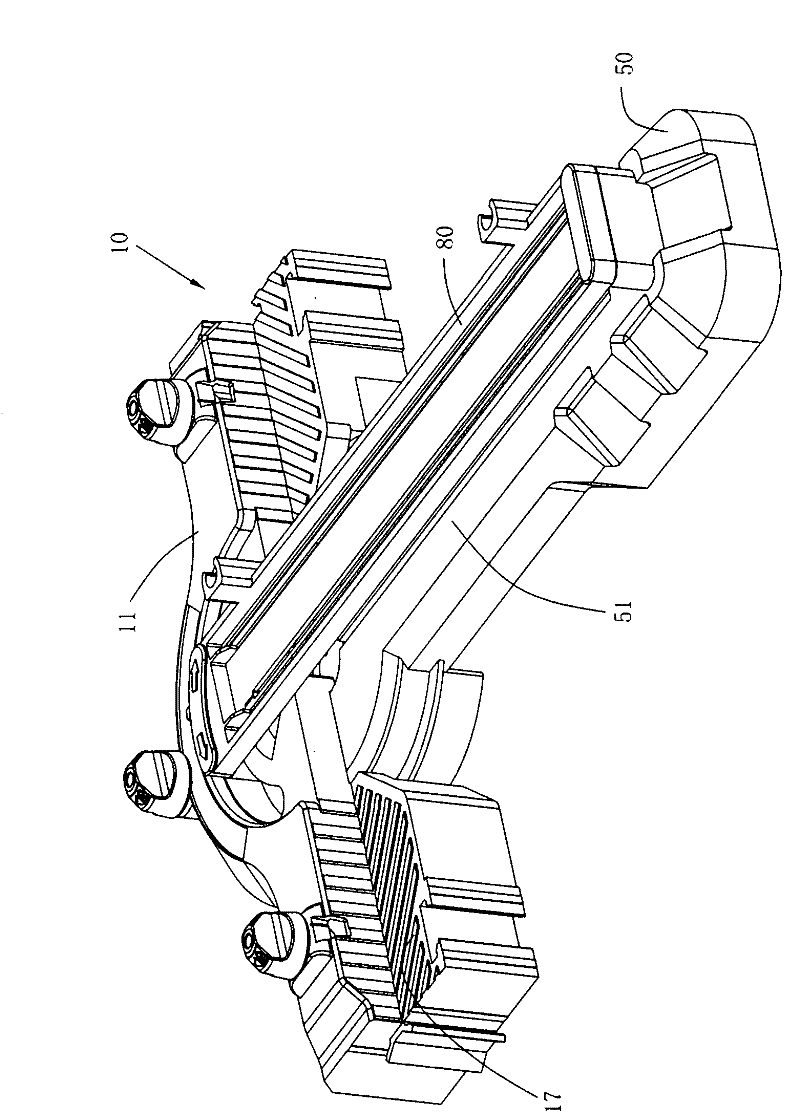

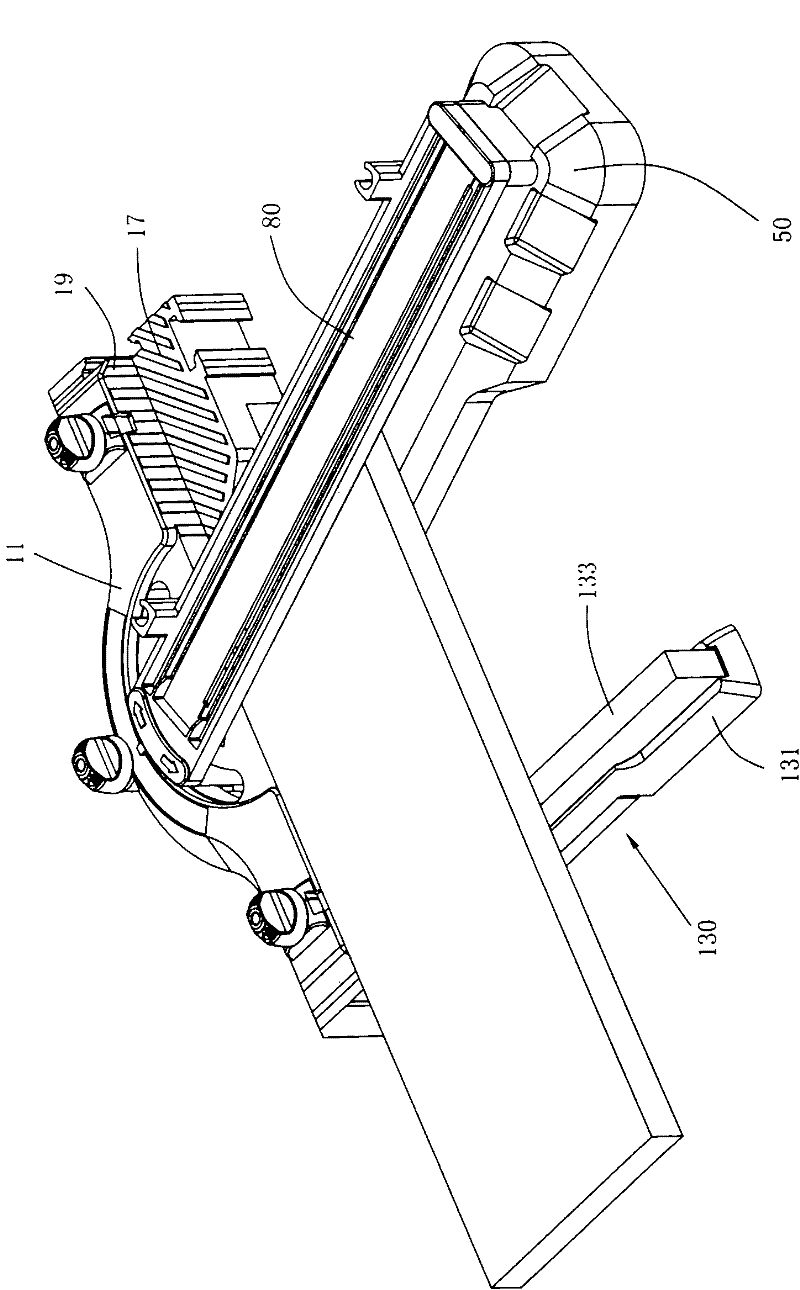

[0075] figure 1 It is a workbench 10 that cooperates with the hand-held cutting machine 1 , and the workbench 10 can support the workpiece to be cut and guide the cutting of the hand-held cutting machine 1 .

[0076] The workbench 10 includes a base 11 , a rotating arm 50 rotatably connected to the base 11 , and a guide rail 80 supported by the rotating arm 50 . The first support plane 17 of the base 11 and the second support plane 51 on the rotating arm 50 jointly support the workpiece to be cut, and the guide rail 80 is matched with the bottom plate 7 of the hand-held cutting machine 1 to guide the hand-held cutting machine 1 along a predetermined track Cutting the workpiece, the predetermined trajectory is usually a straight line.

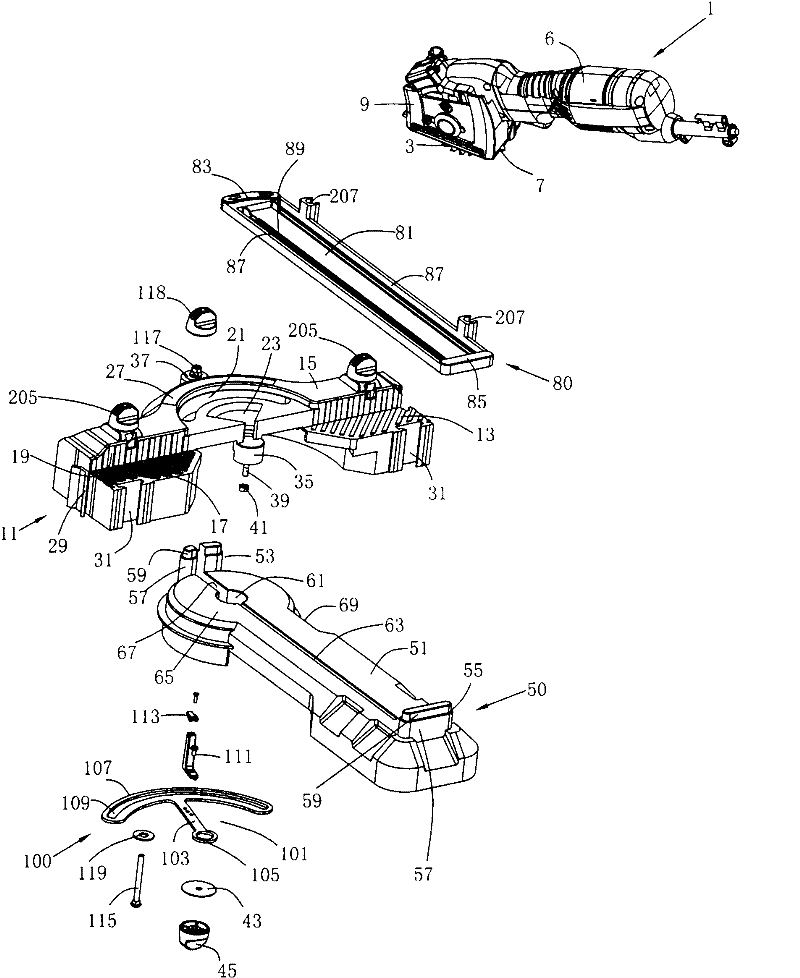

[0077] figure 2 It is an exploded schematic view of the workbench 10 and the matched hand-held cutting machine 1 .

[0078] Such as figure 2 , the hand-held cutting machine 1 includes a working head 3 for processing a workpiece; a motor (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com