Method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation

A lead concentrate, copper sulfide technology, applied in flotation, solid separation and other directions, can solve the problems of unfavorable flotation workshop personnel safety, difficult activation of galena, serious environmental pollution, etc., to achieve good flotation effect and reduce energy. Consumption, the effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

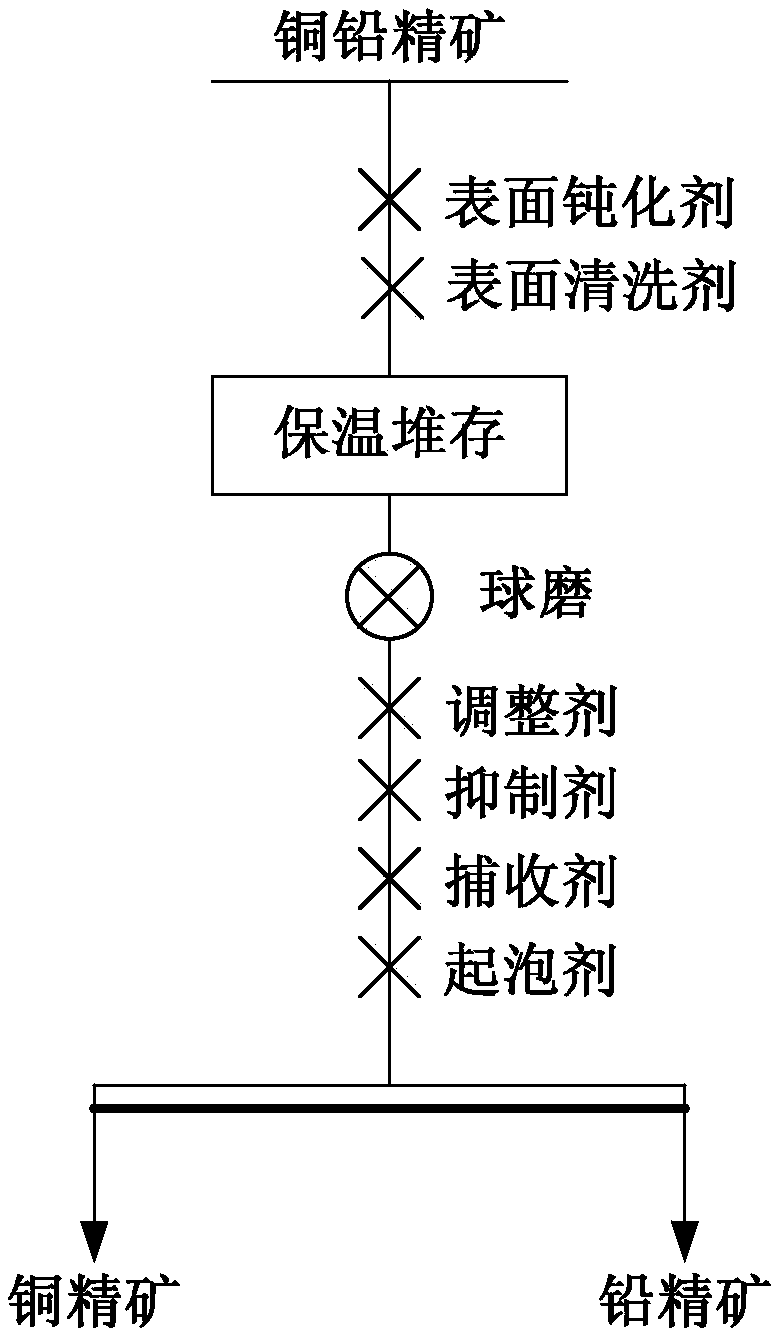

Method used

Image

Examples

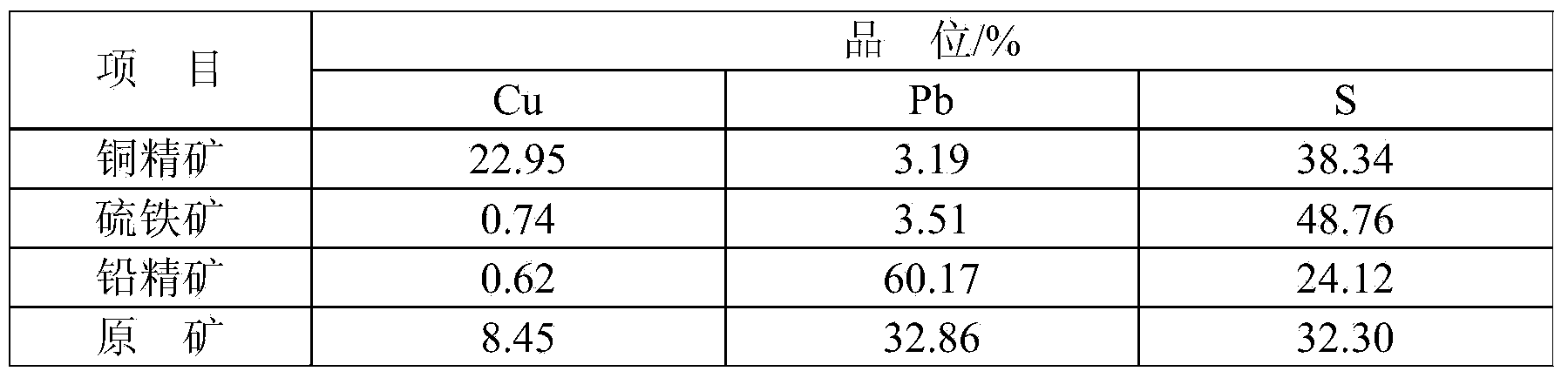

Embodiment 1

[0024] Adopt the method of the present invention to carry out separation industrial experiment to certain import copper sulfide lead concentrate. The ore piles are stacked in 300t piles, add 1 / 200 surface passivation agent solid hydrogen peroxide, mix the mixture with the surface cleaning agent calcium oxide at a ratio of 500:1, cover the mineral wool and keep it warm for 12 days to keep the internal temperature of the ore pile at 60°C. The ore that has completed the pretreatment will enter the ball mill and flotation workshop with an ore feeding rate of 100t / d, and add 0.5kg / t ammonium sulfate, 2kg / t sodium sulfide, 400g / t xanthate and 50g / t The black medicine, 16g / t pine alcohol oil, is separated by flotation according to one rough three fine two sweeps, the separated foam product is chalcopyrite, and the tailings are mainly lead concentrate, but contain a certain amount of pyrite , so continue to add 2.0kg / t of sodium carbonate and 150g / t of butyl xanthate, activate and fl...

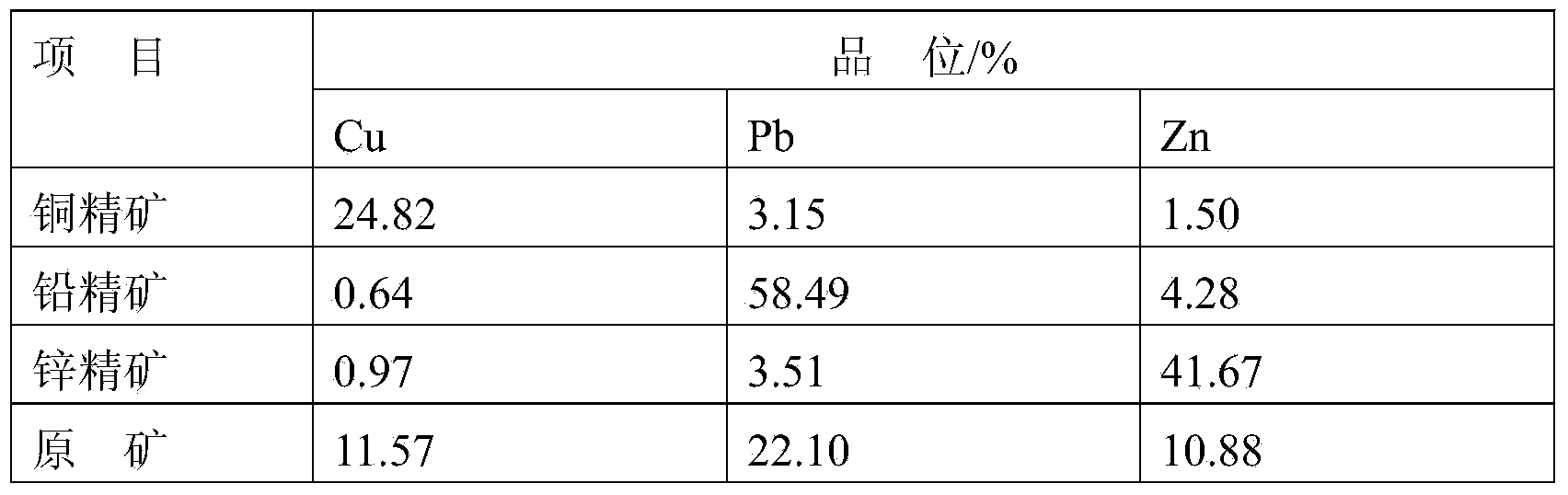

Embodiment 2

[0028] Adopt the method of the present invention to carry out separation industrial experiment to certain import copper sulfide lead concentrate. The ore heap is stacked in 300t piles, and 1 / 350 surface passivation agent sodium persulfate is added; the mixture is then mixed with surface cleaning agent calcium oxide at a ratio of 650:1, covered with mineral wool and kept warm for 10 days to maintain the internal temperature of the ore heap at 70°C. The pretreated ore will enter the ball mill and flotation workshop with an ore feeding rate of 80t / d, and 1.0kg / t of lime, 300g / t of xanthate, 100g / t of black powder and 20g / t of black powder will be added to the process. MIBC, according to the flotation separation of one rough three fine two sweeps, the separated foam product is chalcopyrite, the tailings are mainly lead concentrate, but it contains a certain amount of sphalerite, so continue to add 800g / t copper sulfate and 200g / t of butyl xanthate, activated and flotation to get ...

Embodiment 3

[0032]Adopt the method of the present invention to carry out separation industrial experiment to certain import copper sulfide lead concentrate. The ore piles are piled up in 300t piles, and 1 / 350 of the surface passivator sodium hypochlorite is added; the mixture is then mixed with the surface cleaning agent calcium oxide at a ratio of 500:1, covered with mineral wool and kept warm for 13 days, and the internal temperature of the ore pile is kept at 80 ℃. The ore that has completed the pretreatment will enter the ball mill and flotation workshop with an ore feeding rate of 100t / d, and add 1.0kg / t of lime, 2.5kg / t of sodium sulfite, 150g / t of ethoxynitrogen, and 10g / t of sulfide into the process. The MIBC is separated by flotation according to one rough three fine three sweeps, and the separated foam product is chalcopyrite, and the tailings are mainly lead concentrate, but it contains a certain amount of pyrite, so continue to add 1.2kg / t Copper sulfate and 200g / t butyl xant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com