Screw conveyor

A conveyor and screw technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of short service life of the screw conveying mechanism, reduce the screw conveying efficiency, and the screw cannot fall in, so as to avoid low switching accuracy and avoid jamming. , Improve the effect of installation rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

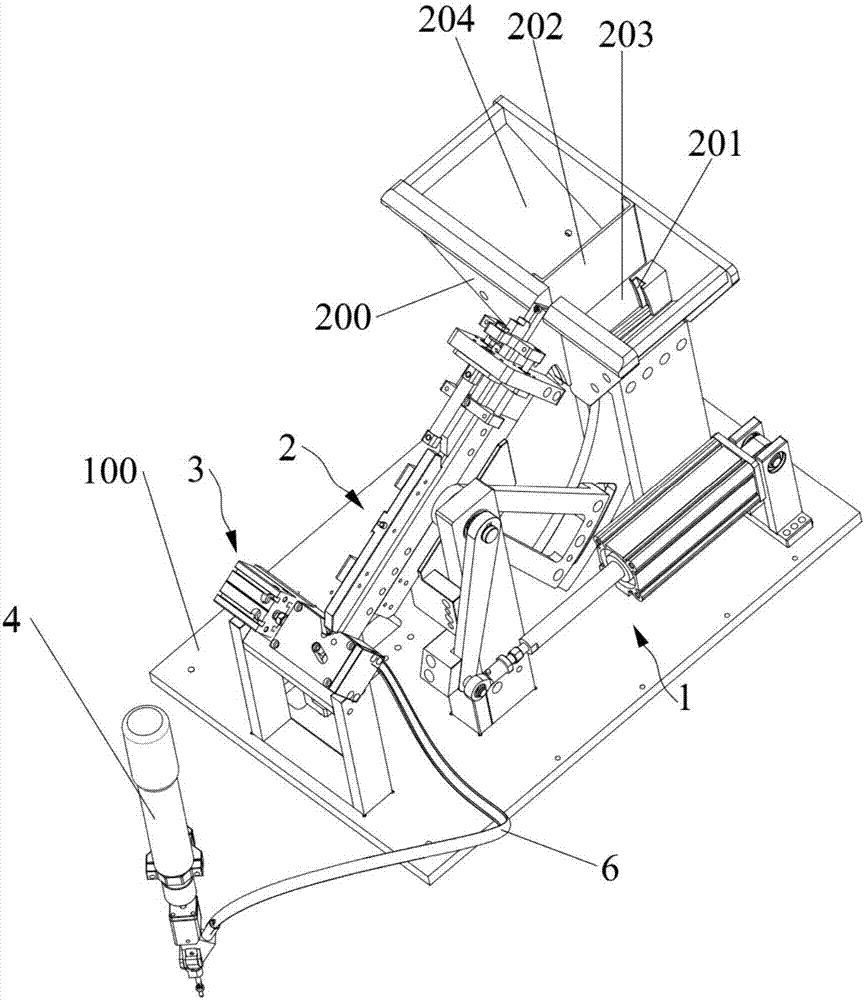

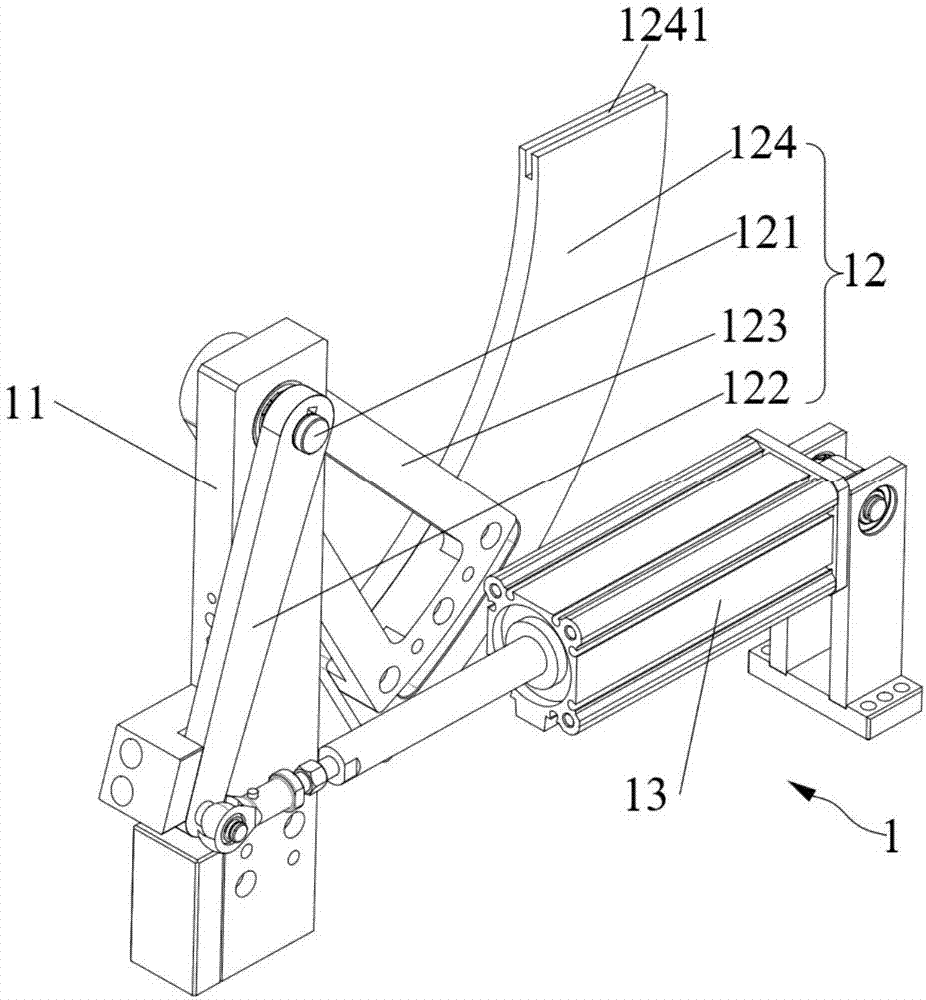

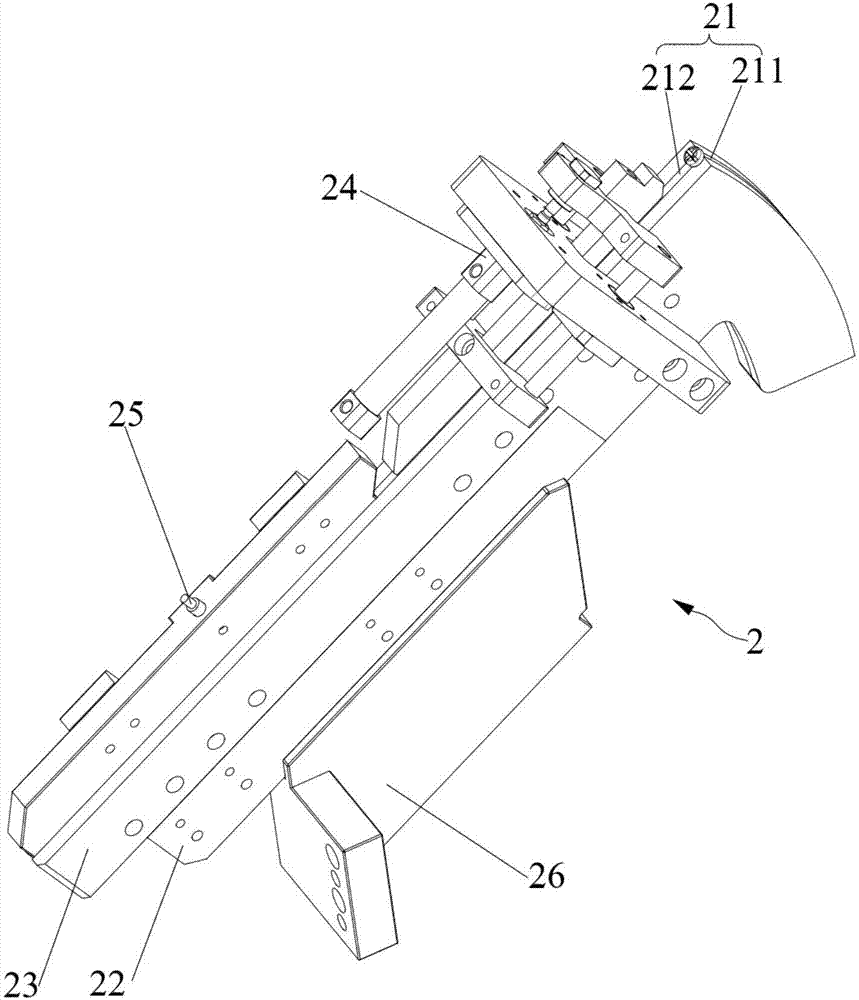

[0059] This embodiment provides a screw conveyor, such as Figure 1-Figure 10As shown, it includes: a base plate 100; a silo 200, which is installed on the base plate 100; a feeding drive mechanism 1, including a support frame 11 fixed on the base plate 100, and a support frame 11 rotatably connected The swing assembly 12, and the drive cylinder 13 connected to the bottom plate 100, the drive cylinder 13 drives the swing assembly 12 to swing, so as to push the screws in the feed bin 200 to move upward; the discharge mechanism 2, which tilts Set on the support frame 11, one end of the discharge mechanism 2 passes through one side of the silo 200, the discharge mechanism 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com