Rotary scrubbing control device capable of cleaning bearings with different sizes

A control device and bearing technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of high cost, low replacement efficiency, poor cleaning effect, etc. The effect of reducing cleaning costs and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described

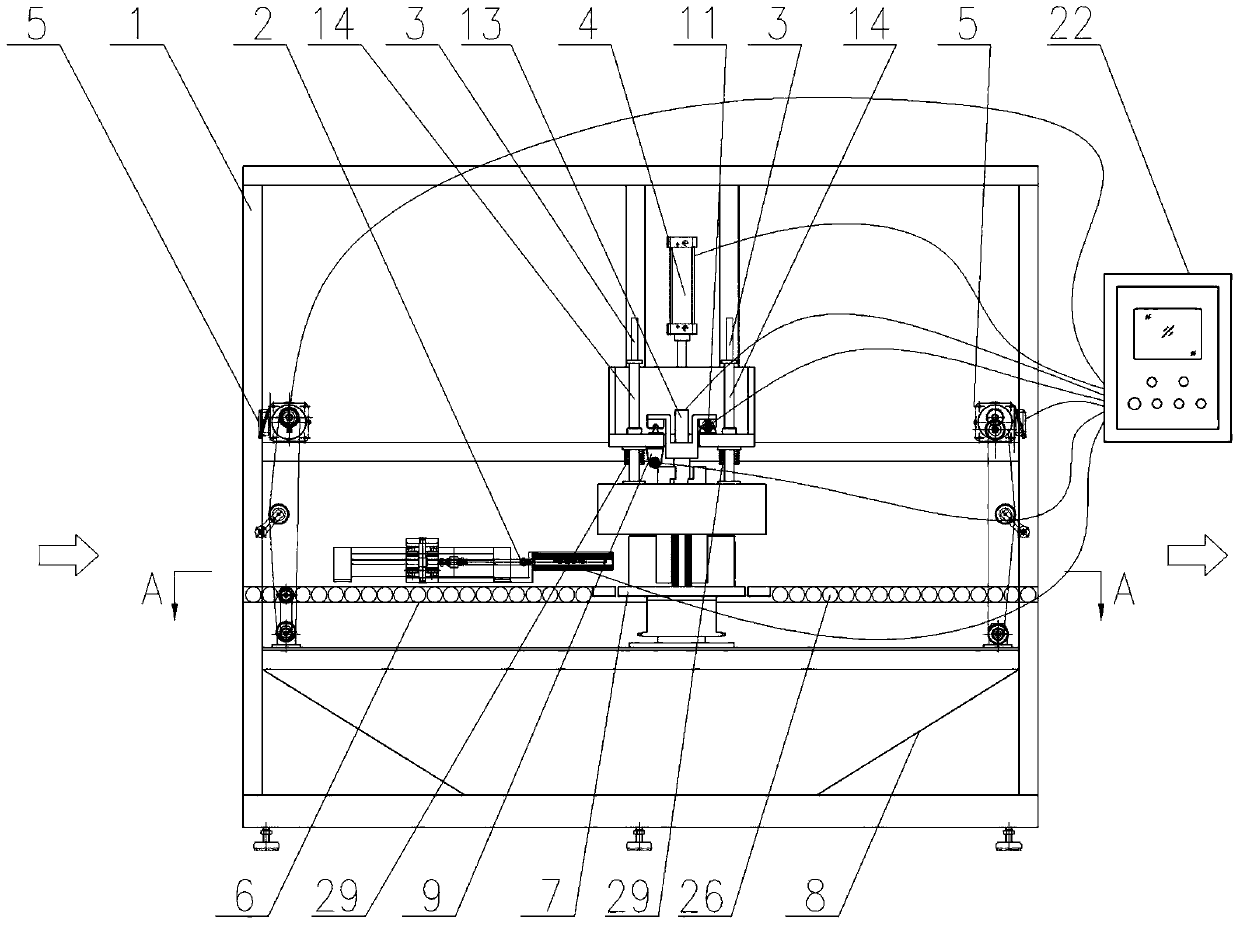

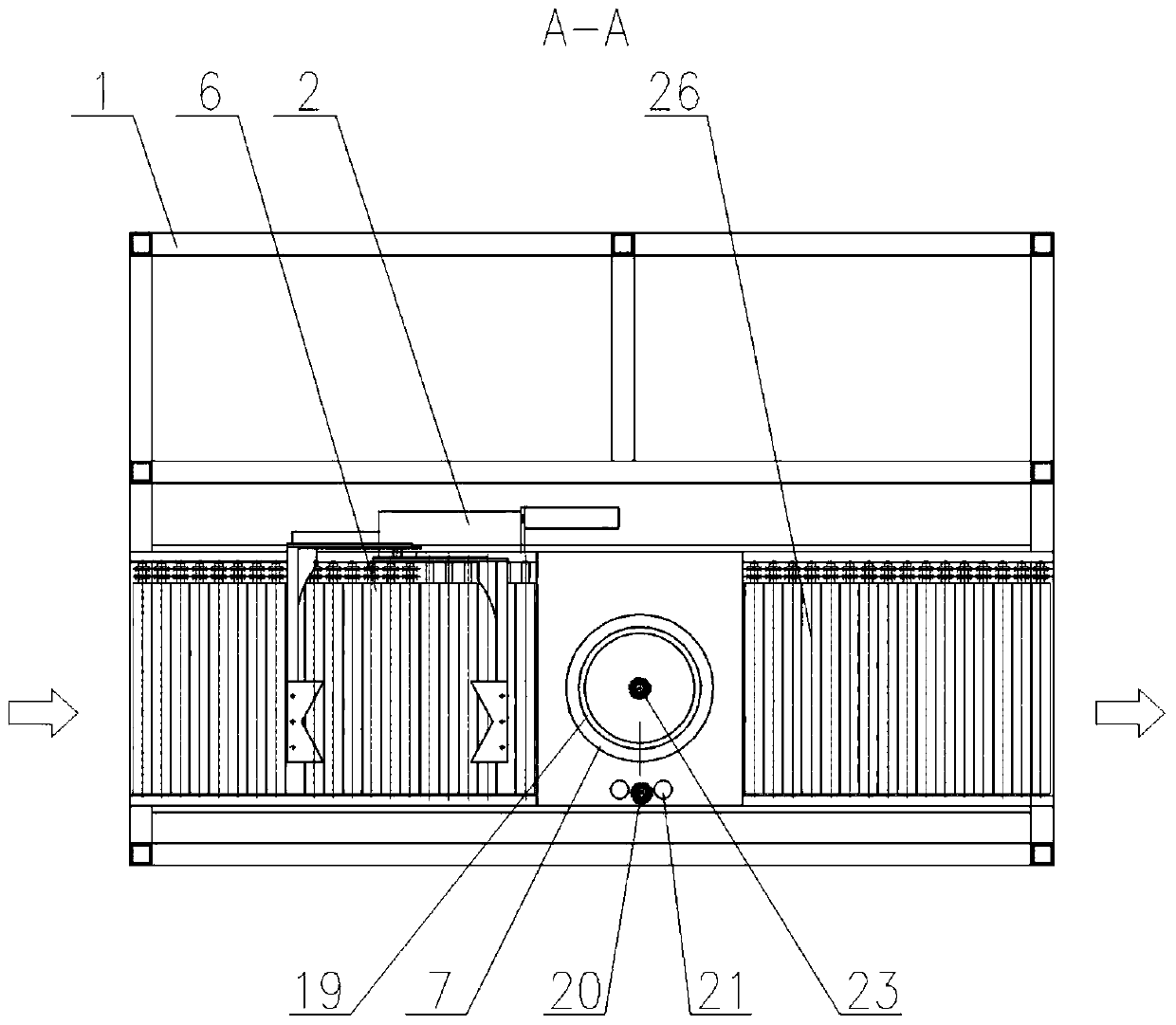

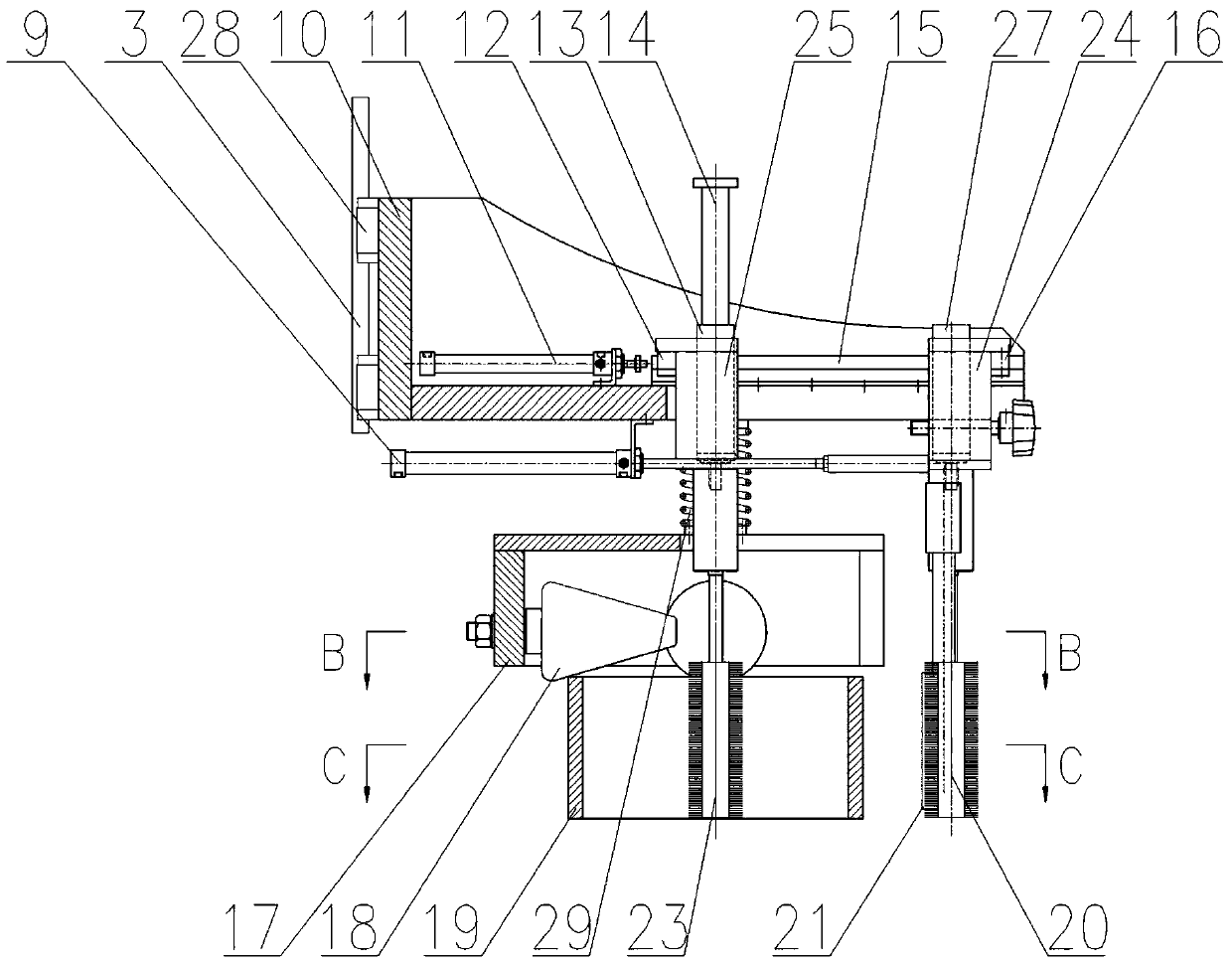

[0020] A rotary scrubbing control device capable of cleaning bearings of different sizes is composed of a frame 1, a feeding transmission belt 6, a discharge transmission belt 26, a clamping and transporting mechanism 2 and a rotary scrubbing control device. Frame 1 is a truss structure for fixing various components; the feeding drive conveyor belt 6 and the discharge drive conveyor belt 26 are disconnected and fixed horizontally on the frame 1; The rotary scrubbing control device is fixed between the transmission conveyor belts 26; the clamping and transporting mechanism 2 is fixed on the frame 1 for placing the cleaning bearing 19 on the feeding transmission belt 6 into the rotary scrubbing control device, and then cleaning the bearing 19 after cleaning is completed. Place it on the discharge transmission conveyor belt 26; the motor 5 drives the conveyor belt to run.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com