Paper feeding mechanism of paper vessel molding machine

A technology for forming machines and paper containers, applied in paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of complex conveying mechanism, high production cost, low production efficiency, etc., and achieve the effect of reasonable layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

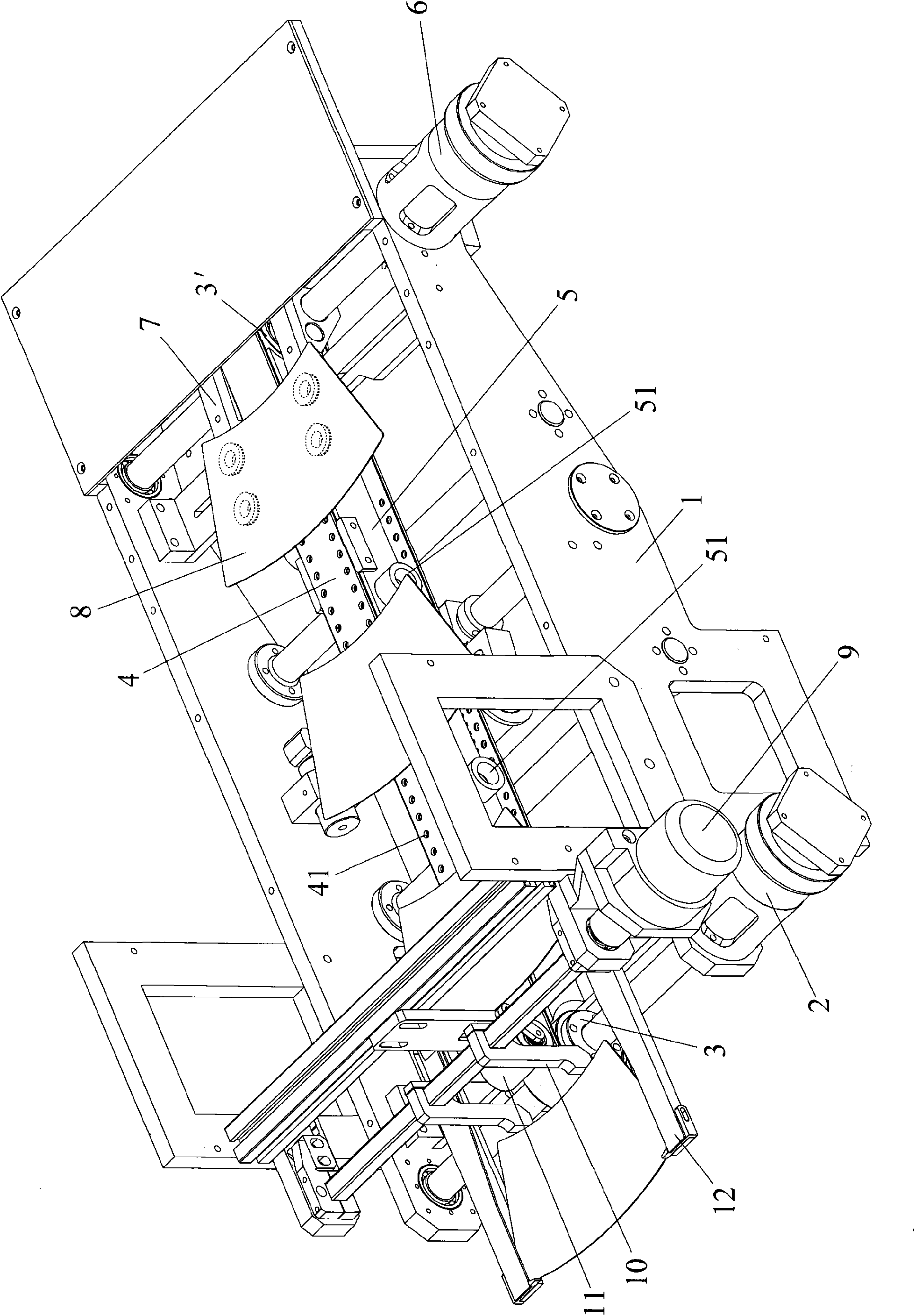

[0011] Example: see figure 1 , the present invention is provided with the feeding driving wheel 3 at the front end of the frame 1, and the feeding driven wheel 3' is set at the rear end of the frame 1, and the feeding belt 4 is set on the feeding driving wheel 3 and the feeding driven wheel 3', and the feeding is driven. A vacuum frame 5 is set between the wheel 3 and the feeding driven wheel 3′, and the vacuum chamber of the vacuum frame 5 is connected to the vacuum generator through the vacuum hole 51, and the vacuum generator works so that the vacuum chamber of the vacuum frame 5 generates negative pressure; the feeding belt 4 By being located on the upper panel of the vacuum rack 5, several holes or grooves are set on the upper panel of the vacuum rack 5, so that when the feeding belt 4 moves, there are always air holes 41 to communicate with the vacuum cavity of the vacuum rack 5; A push claw 10 is arranged on the shaft, and a positioning frame 12 is arranged at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com