Full automatic pipe cutting machine

A pipe cutting machine, fully automatic technology, applied in the direction of pipe shearing device, shearing device, shearing machine accessory device, etc., can solve the problem of unsatisfactory high-precision products, affecting the straightness of pipe cutting, and high labor intensity of operators and other problems, to achieve the effect of high degree of automation, high cutting efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

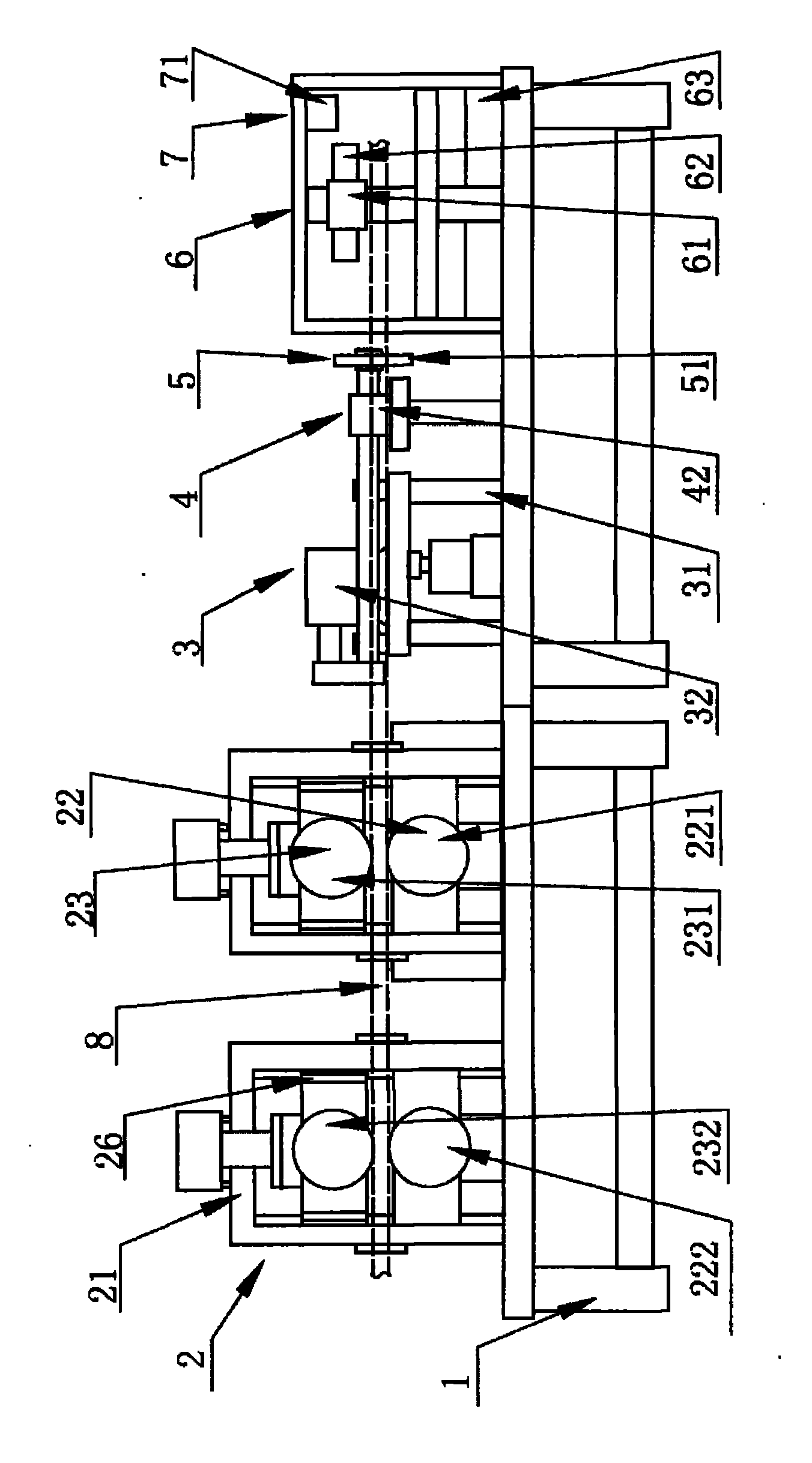

[0026] Such as figure 1 , figure 2 As shown, the present invention is a fully automatic pipe cutting machine, which includes a feeding drive part 2, a cutting drive part 3, a pipe fitting clamping part 4, a cutting part 5, and a discharge part, which are sequentially arranged on a workbench 1. 6 and the cutting and measuring part 7; the feeding driving part 2 includes a driving bracket 21, and the driving bracket 21 is provided with a vertically distributed driving wheel 22 and a rolling wheel 23, and the driving wheel 22 is connected to the step by a driving shaft 24. The feeder motor 25 is connected, and the rolling roller 23 is connected with the up and down adjustment mechanism 26 arranged on the driving bracket 21; the cutting driving part 3 includes a Slide rail 31, the cutting driving mechanism 32 of pipe fitting 8 is provided on the described workbench 1 of the side of described slide rail 31; Described pipe fitting clamping part 4 comprises the driving part 42 of pi...

Embodiment 2

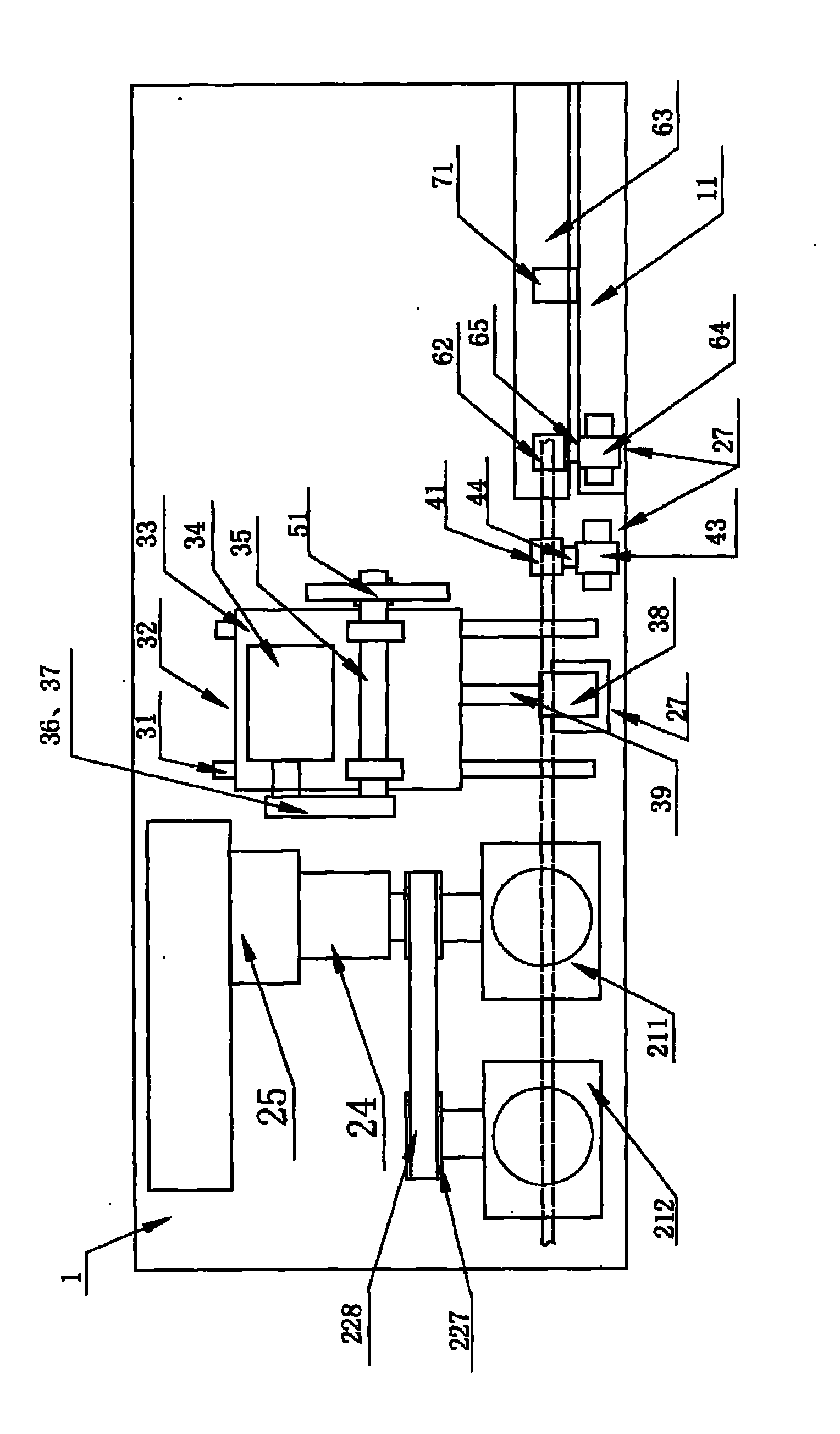

[0028] As shown in the picture, image 3As shown, on the basis of Example 1, in order to enable the cut pipe to be fed straight forward, and at the same time in order to increase the driving friction of the feed and distribute the friction evenly on the conveyed pipe, the The driving bracket 21 includes a main driving bracket 211 and an auxiliary driving bracket 212 arranged in a straight line, and a main driving wheel 221 and an auxiliary driving wheel 222 are respectively arranged on the main driving bracket 211 and the auxiliary driving bracket 212. The driving wheel 221 and the auxiliary driving wheel 222 are respectively supported on the main driving bracket 221 and the auxiliary driving bracket 222 through the main driving shaft 223 and the auxiliary driving shaft 224. A bearing 225 and a bearing bracket 226 are arranged between the main driving bracket 211 and the auxiliary driving bracket 212, and the bearing bracket 226 is closely matched with the main driving bracket...

Embodiment 3

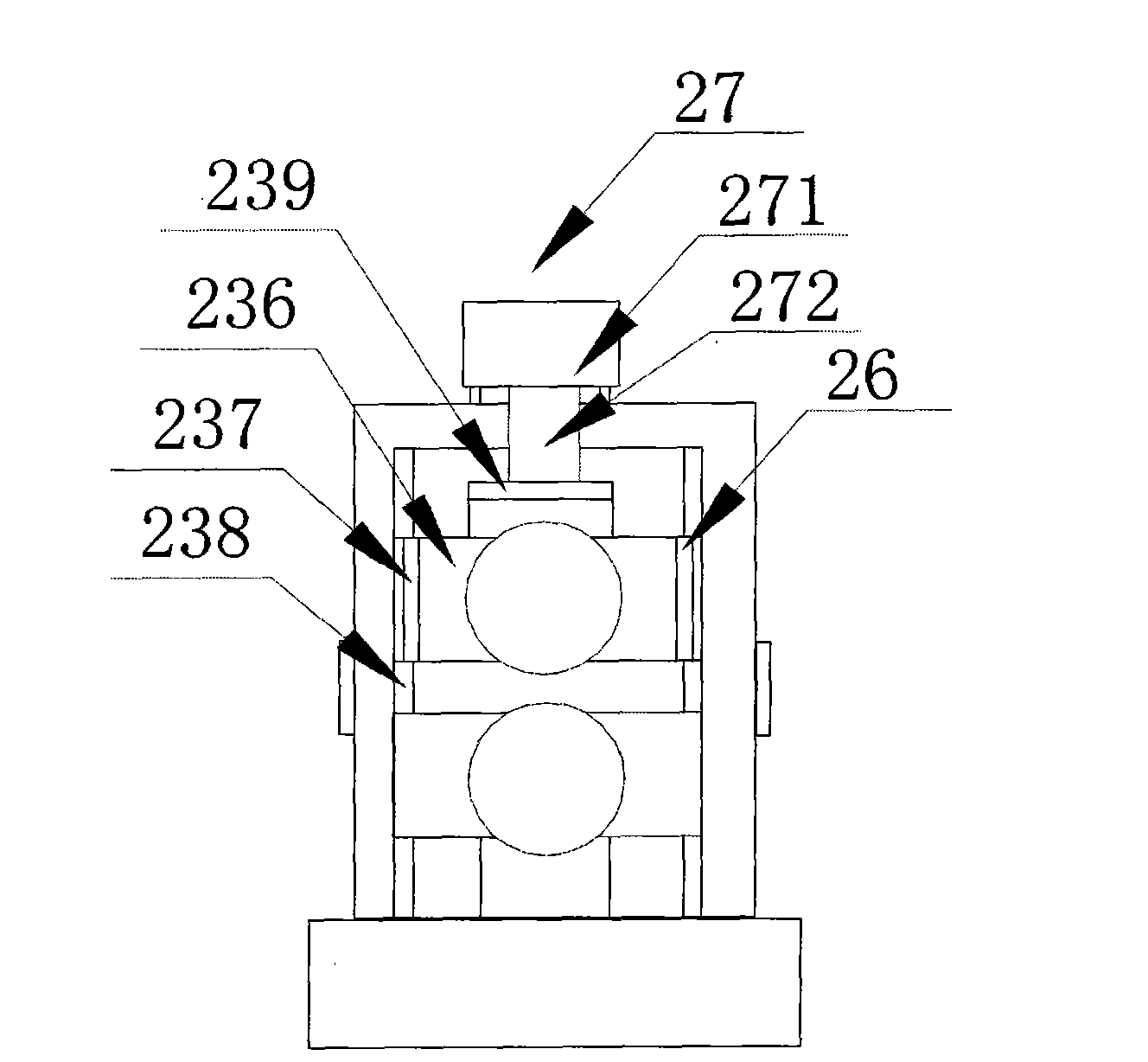

[0030] Such as figure 1 , Figure 4 As shown, on the basis of Embodiment 2, in order to make the driving bracket suitable for cutting pipes of different specifications, and at the same time to easily adjust the friction force in the pipe fittings transmission process, on the main driving bracket 211 and the auxiliary driving bracket 212 Main rolling wheel 231 and auxiliary rolling wheel 232 are also provided respectively. The bearings 235 and the bearing brackets 236 on both sides of the auxiliary rolling shaft 234 are connected with the vertical adjustment mechanism 26 on the main driving bracket 211 and the auxiliary driving bracket 212 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com