Automatic pearl drilling device

A drilling device and pearl technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of high installation accuracy and movement accuracy, unstable pearl positioning, etc., to improve drilling efficiency and increase drilling efficiency. Hole efficiency, the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

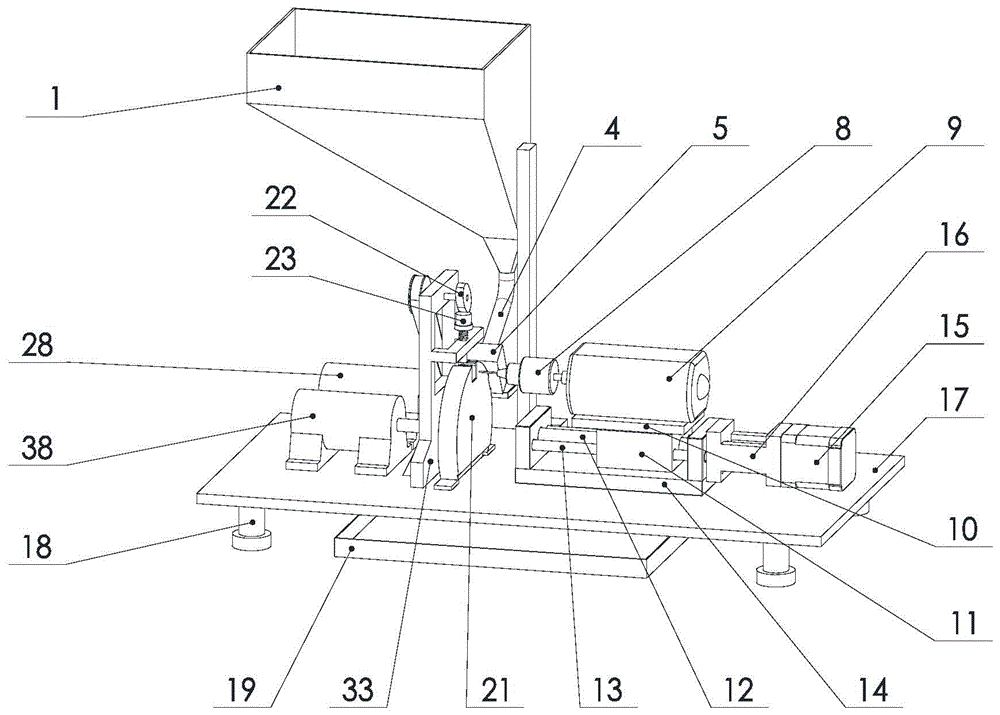

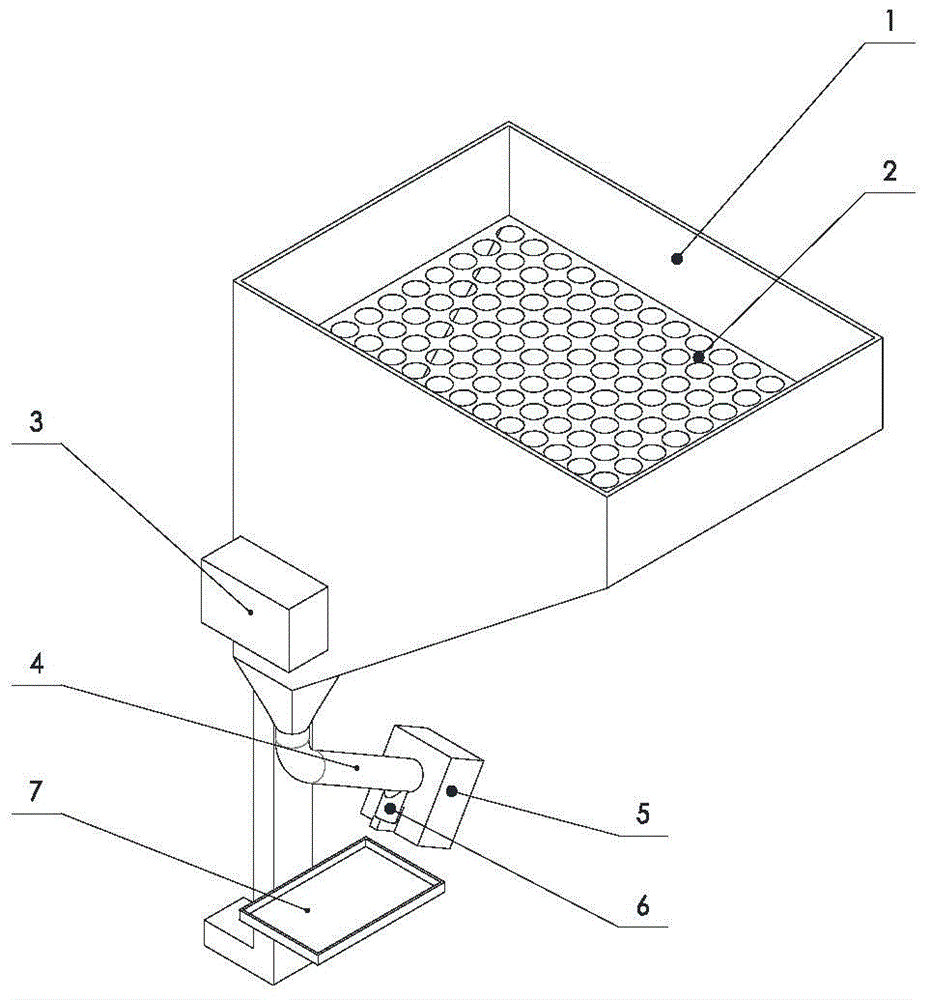

[0050] refer to Figure 1-14 , to further illustrate the present invention:

[0051] An automatic pearl drilling device, which has a frame, on which a hopper 1, a clamping mechanism, a drilling mechanism, a feeding mechanism connecting the hopper 1 and the clamping mechanism, and a discharge mechanism for discharging drilled pearls are provided. material organization.

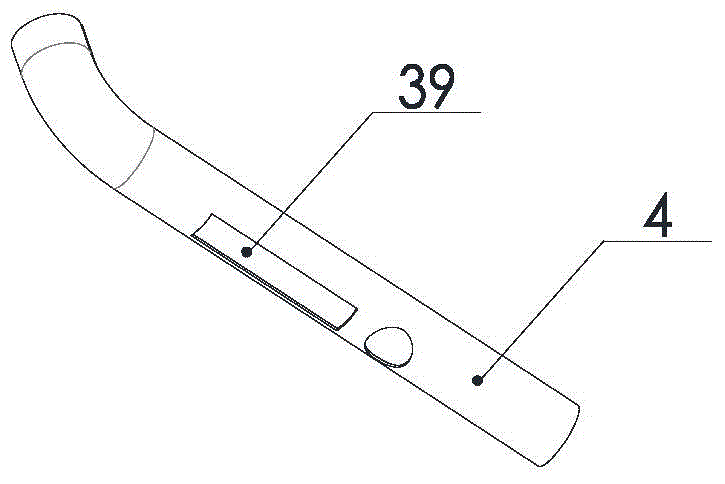

[0052] The feeding mechanism includes a material guide pipe 4 that communicates with the hopper 1 and allows only a single row of pearls to pass through, a material guide that moves a single pearl from the feeding station to the drilling station and the discharging station in sequence, and a connecting guide. The material pipe 4 is connected to the feeding part of the feeding station; the feeding part only allows one pearl to enter the feeding station at a time; the drilling station is aligned with the drilling mechanism, and the discharging station is connected with the discharging mechanism. The feed pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com