Full-automatic manufacturing method for chip winding inductors and equipment employing full-automatic manufacturing method

A technology of wire-wound inductors and manufacturing methods, which is applied in the manufacture of inductors/transformers/magnets, coils, circuits, etc., and can solve the problems of long waiting time for loading materials, low work efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

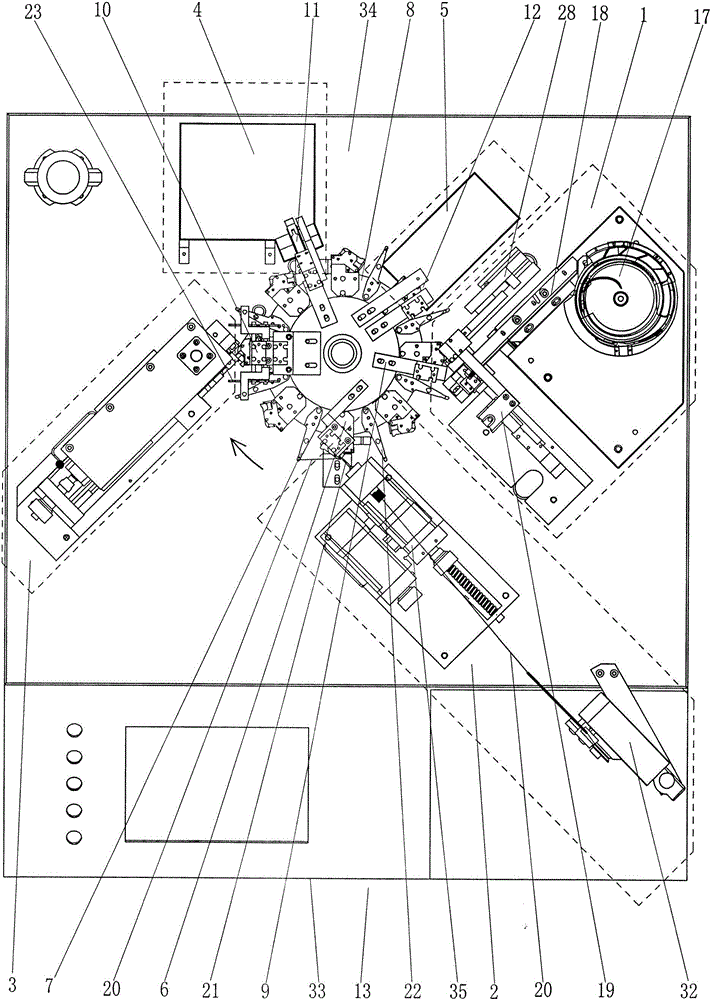

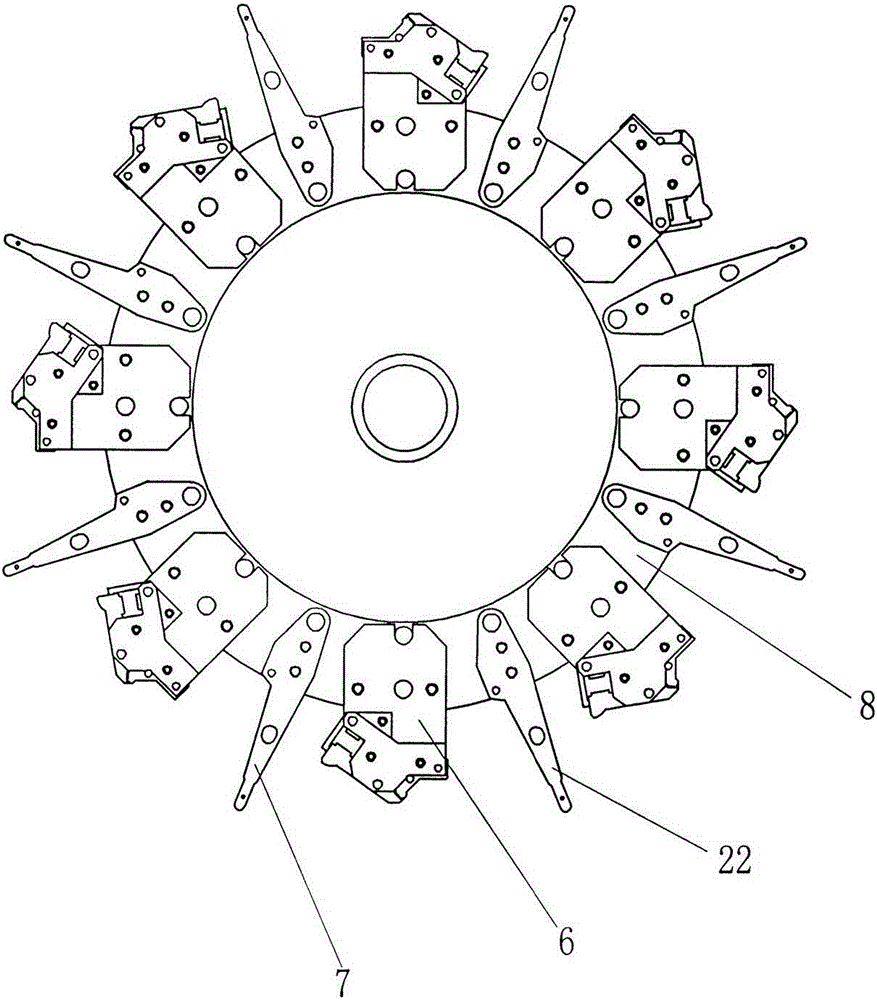

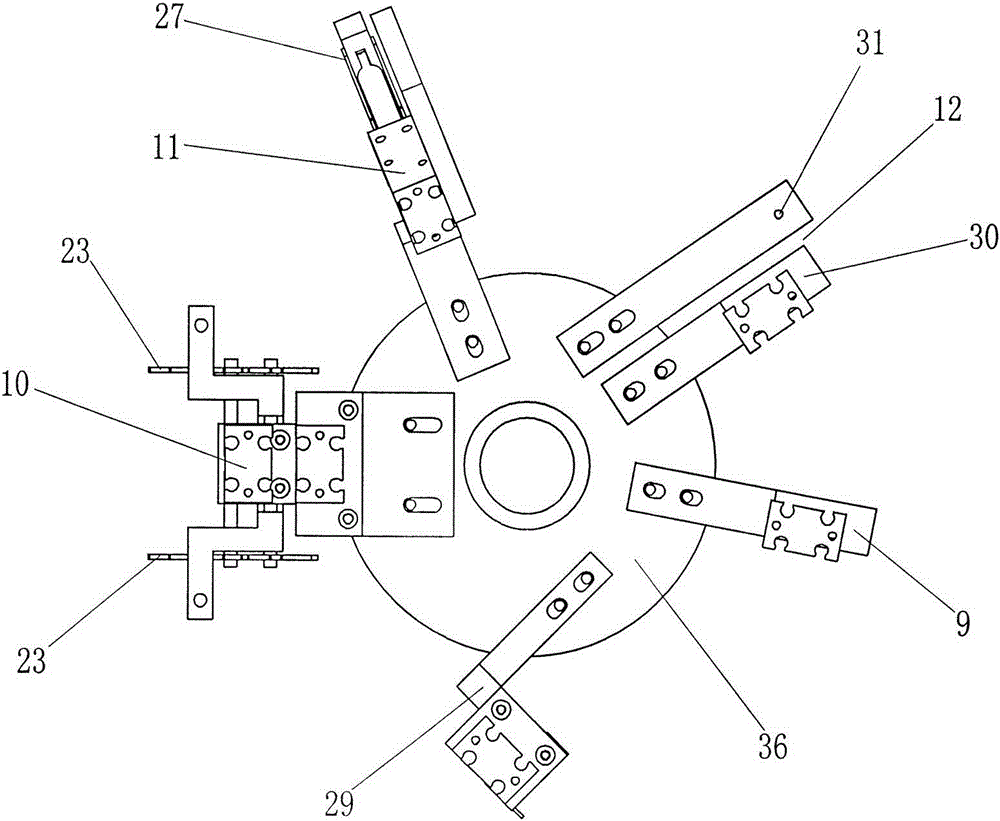

[0032] refer to Figure 1 to Figure 5 , the fully automatic manufacturing method of the chip-type wound inductor is characterized in that a feeding mechanism 1, a wire supply winding mechanism 2, a welding mechanism 3, a waste collection container 4 and a finished product collection container 5 are arranged in a Around the transmission turntable 8 that several clampers 6 etc. and several wire racks 7 etc. are arranged alternately, the clamper feeding drive mechanism 9, the crimping mechanism 10, the wire arranging mechanism 11 and the unloading mechanism 12 are arranged in the said conveying On the fully automatic equipment 13 above the turntable 8, the ceramic cores are placed one by one on the fully automatic equipment 13 to complete the operation process of feeding, clamping and fixing, winding, welding, arranging wires, and unloading, specifically as follows The steps are constituted sequentially:

[0033] ① Put the ceramic cores 16 etc. coated with metal electrodes 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com