Core-rod grinding device

A grinding machine and mandrel technology, applied in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve problems such as difficult to ensure environmental sanitation, difficult to strictly ensure quality, and harsh working environment. To achieve the effect of ensuring physical health, stable product quality, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

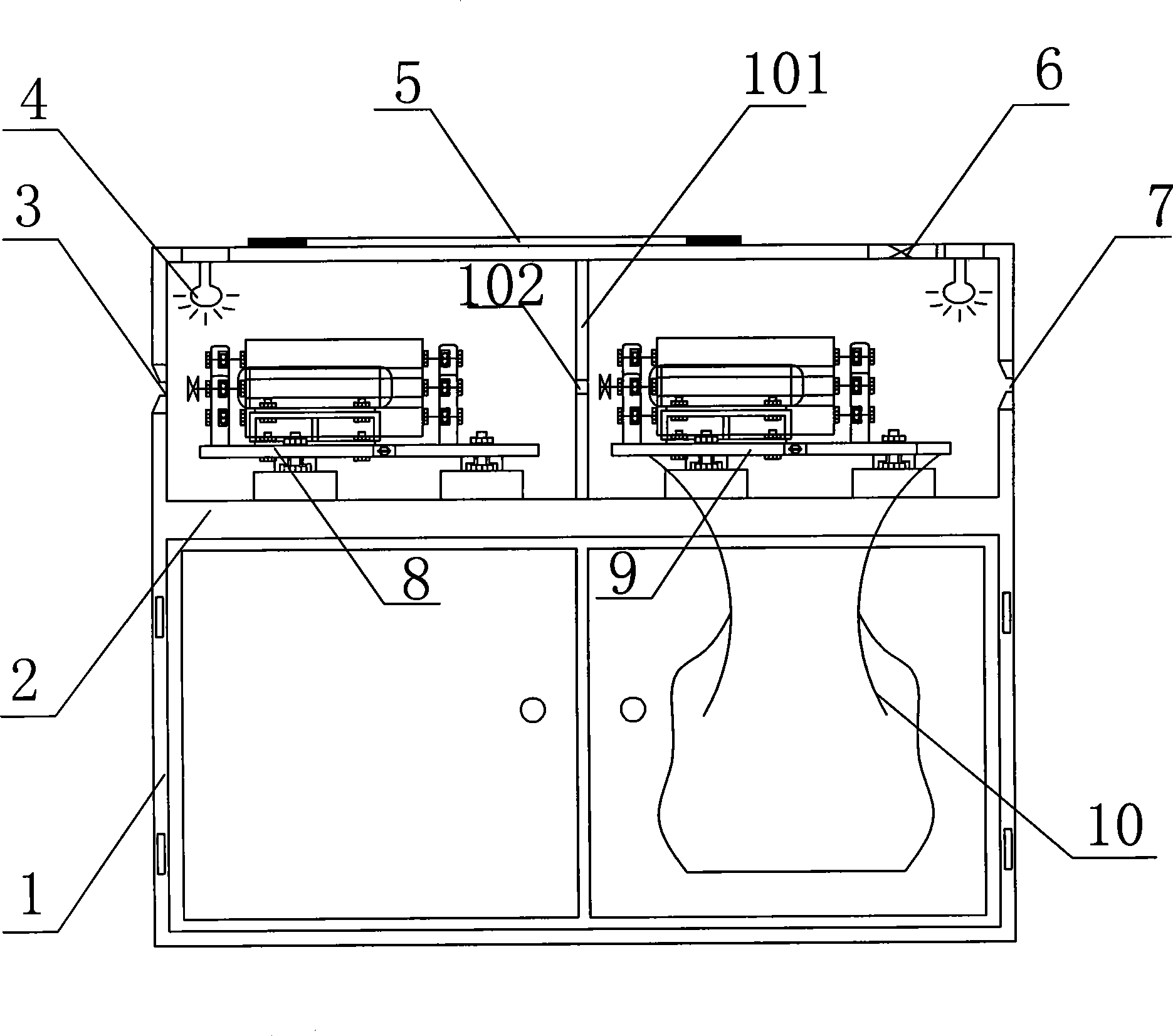

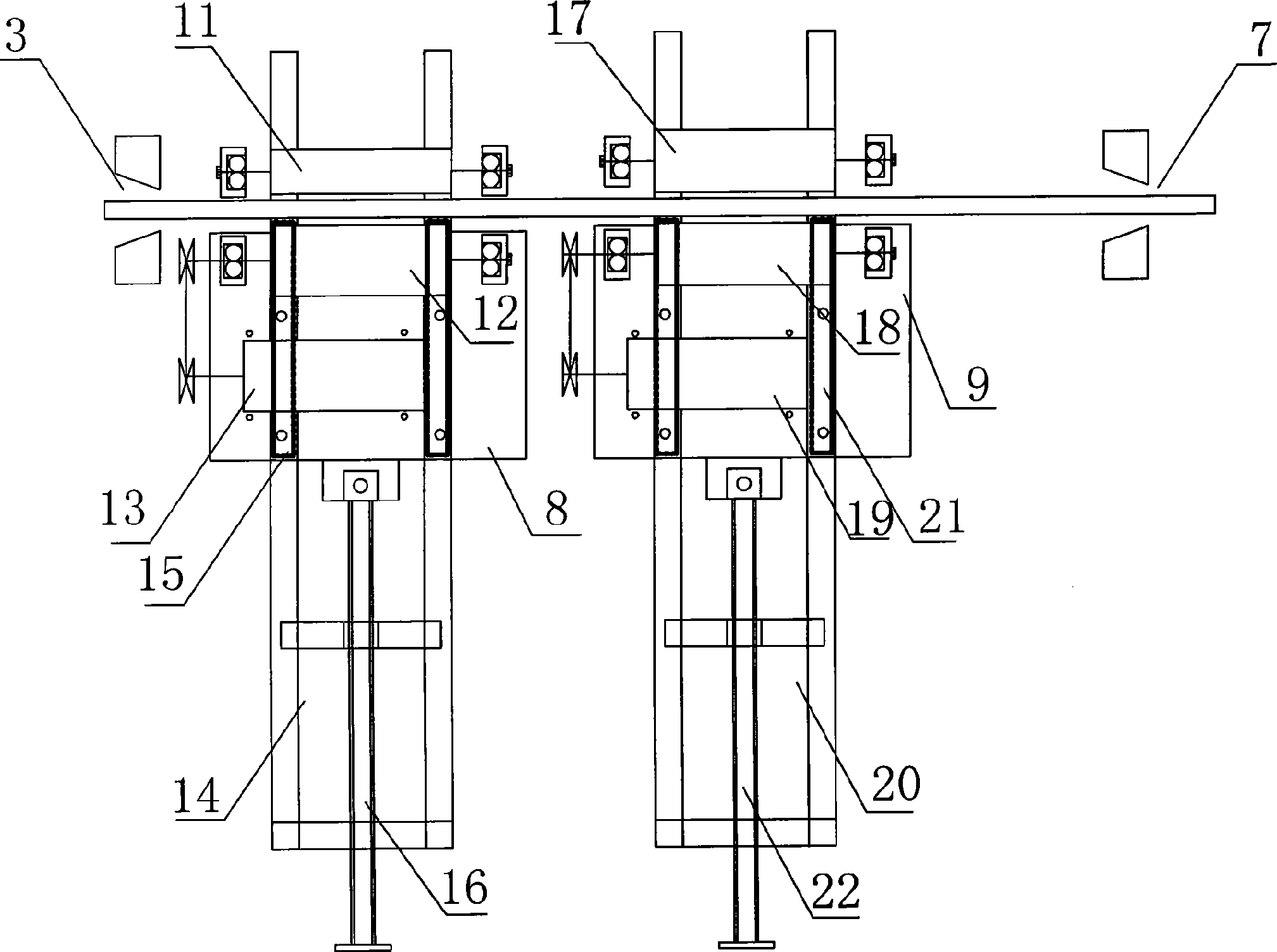

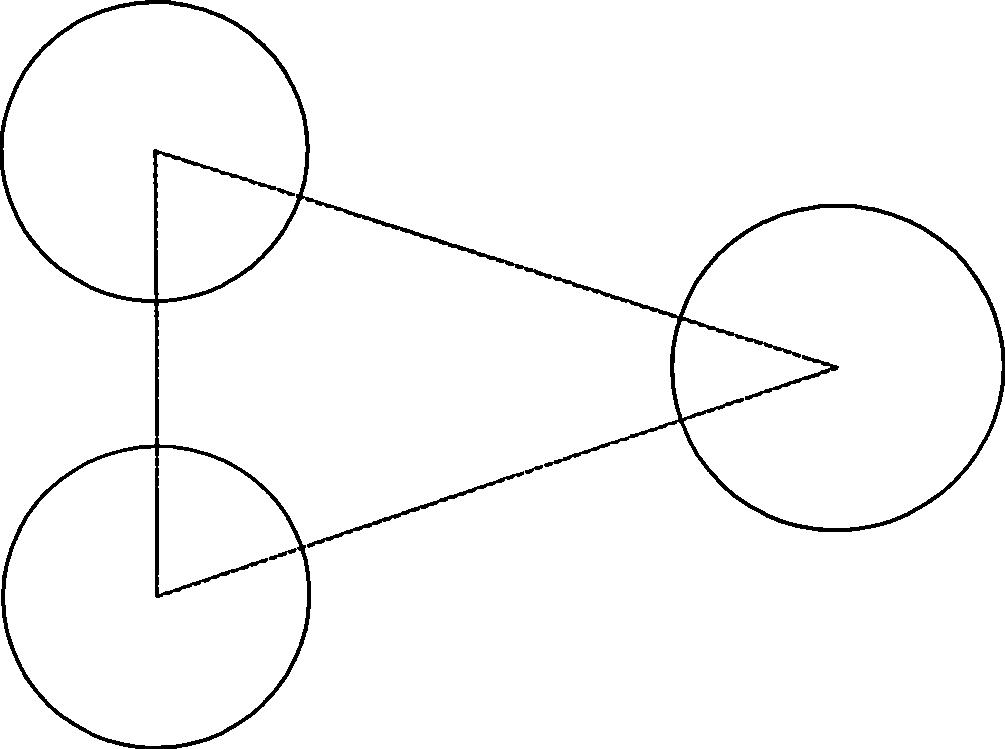

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown: the mandrel grinding machine includes a rod feeding platform 8 and a grinding rod platform 9 on the outer cover 1 and the frame 2, the outer cover 1 is provided with the rod feeding port 3 and the rod outlet port 7, and the middle part of the outer cover 1 has Partition 101, partition 101 is provided with rod passing port 102; rod feeding platform 8 is provided with two rod feeding driven wheels 11 and rod feeding driving wheel 12 arranged horizontally up and down, and rod feeding driving wheel 12 is connected with rod feeding motor 13. connected, the rod feeding cross-section A formed by the two rod feeding driven wheels 11 and the rod feeding driving wheel 12 is an inverted isosceles triangle; Wheel 18, the grinding rod driving wheel 18 is connected with the rod feeding motor 19, the grinding rod dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com