Multi-material 3D printer

A 3D printer and multi-material technology, applied in typewriters, printing, additive processing, etc., can solve problems such as troublesome operation, affecting product printing quality, and affecting effective molding size, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

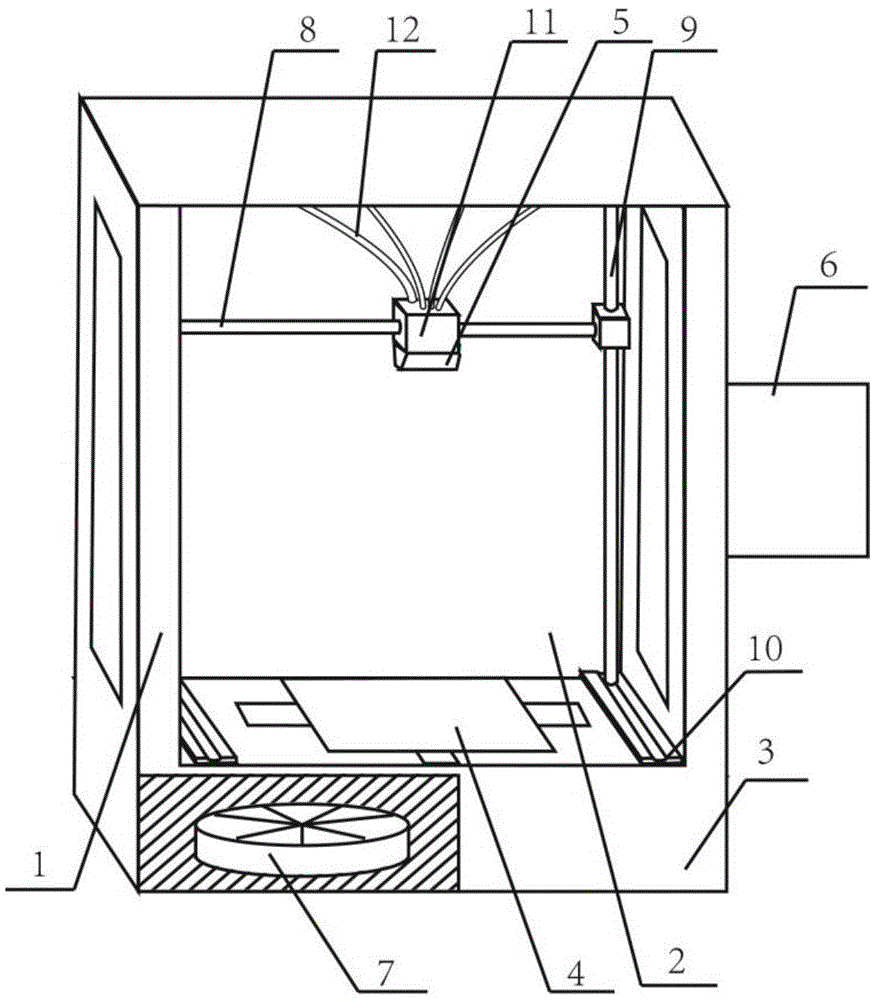

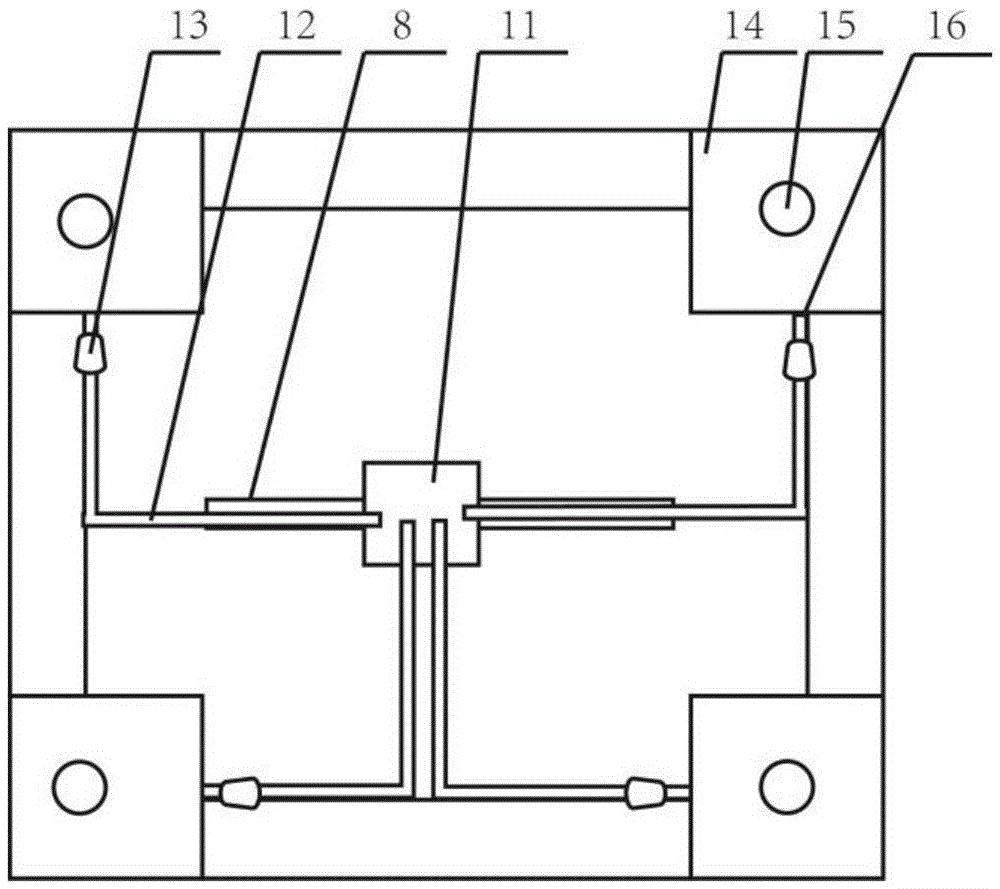

[0027] A multi-material 3D printer, the 3D printer includes a shell, the shell includes a front door 1, a rear wall 2 and two side walls, a base 3, a workbench 4, a nozzle 5, and a three-dimensional motion mechanism are arranged in the shell , a feeding unit and a storage unit, the 3D printer is connected to the controller 6, the controller 6 adopts a single-chip microcomputer, the base 3 is provided with a power supply, the controller 6 is connected to the power supply, and the three-dimensional movement The mechanism is driven by a servo motor 7, and the servo motor 7 is electrically connected to the controller 6. The three-dimensional motion mechanism includes an X-axis motion mechanism, a Y-axis motion mechanism and a Z-axis motion mechanism, and the X-axis motion mechanism is an X-axis sliding mechanism. Guide rail 8, the nozzle 5 can slide left and right on the X-axis sliding guide rail 8, the Y-axis motion mechanism includes two Y-axis sliding guide rails 9 symmetrically...

Embodiment 2

[0031] When using the present invention to 3D print circuit boards, the required materials (such as conductive ink, etc.) are placed in the storage tank, and the graphics and material data of the printed circuit boards are first processed by computer software to design a three-dimensional print that needs to be printed. The three-dimensional model of the solid object is sliced and layered along the computer internal direction corresponding to the actual vertical direction to obtain the forming data of each layer. Afterwards, the graphic information data corresponding to the material is sent to the valve controller corresponding to the material, and the nozzle is driven by the three-dimensional motion mechanism and under the action of the feeding drive device, and the required circuit is printed layer by layer on the workbench plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com