Crushing mechanism of plastic crusher

A technology of plastic crusher and crushing mechanism, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of inconvenient installation and maintenance, irregular cutting, complex structure, etc., to reduce the generation of powder, cutting The effect of neat material and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

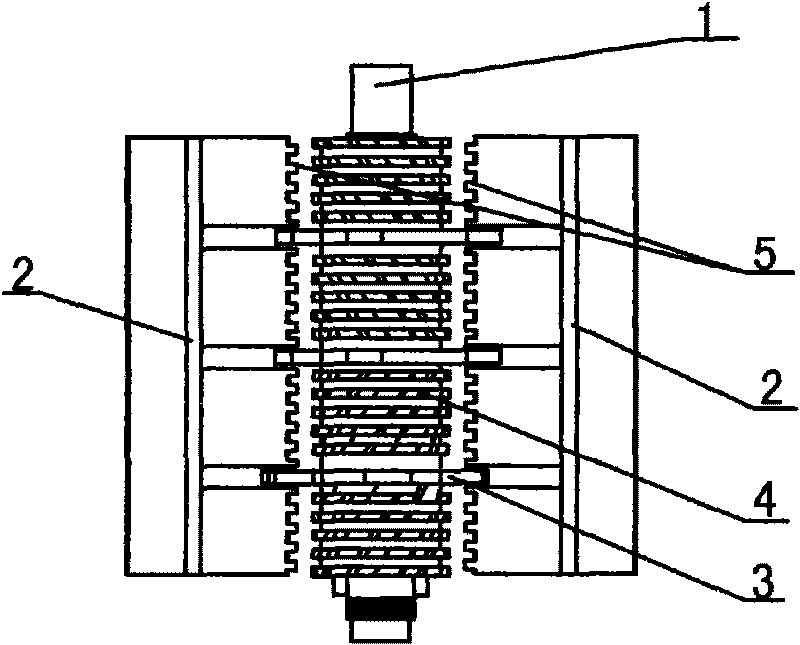

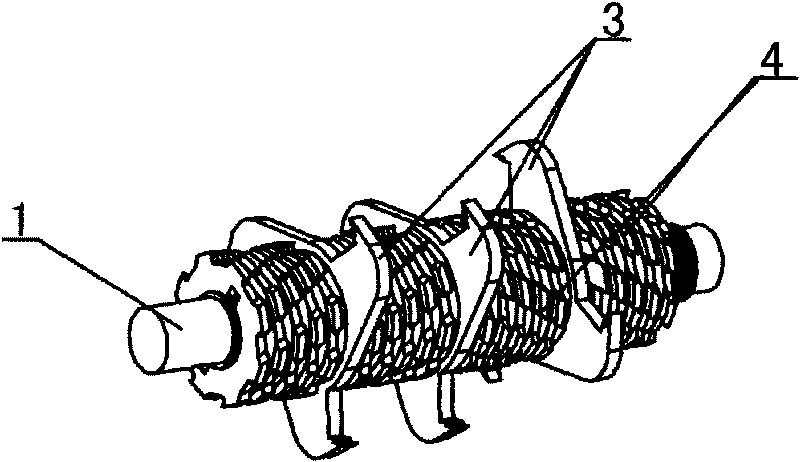

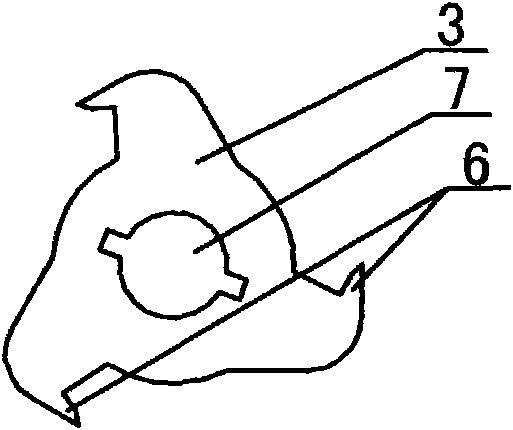

[0016] Such as Figure 1-6 As shown, the crushing mechanism of the plastic crusher described in the embodiment of the present invention includes a transmission shaft 1, a fixed knife 2 and a moving knife set, and the moving knife set includes three identical pressing knives 3 and four circular knives 4, the central positions of the press knife 3 and the round knife 4 are provided with a concentric press knife shaft hole 7 and a round knife shaft hole 8, and are installed on the transmission shaft 1 through the shaft hole, and the press knife 3 is trilobate Spiral structure and each pressing knife 3 is provided with three R-shaped pressing knife edges 6; several blades of the circular knife 4 are arranged in a spiral V-shaped structure as a whole and each circular knife 4 is provided with several R-shaped circular knife edges 9 A group of fixed knives 2 are arranged on both sides of the moving knife group and a fixed knife edge 5 matching the moving knife part is provided. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com