Device for clipping rubber rings

A technology of a rubber ring and a driving device is applied in the processing field of rubber rings, which can solve the problem of not being able to cut multiple rubber rings at the same time, and achieve the effects of simple structure, convenient operation and neat position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

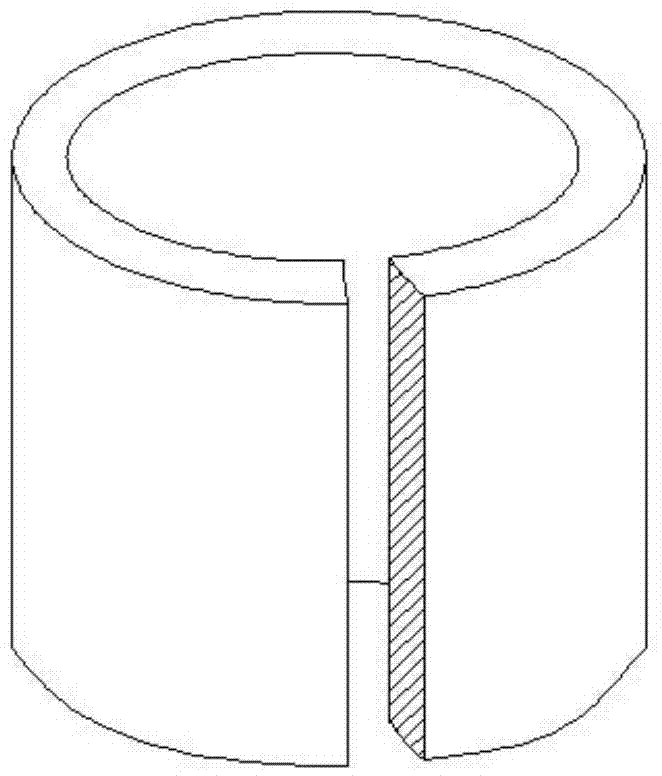

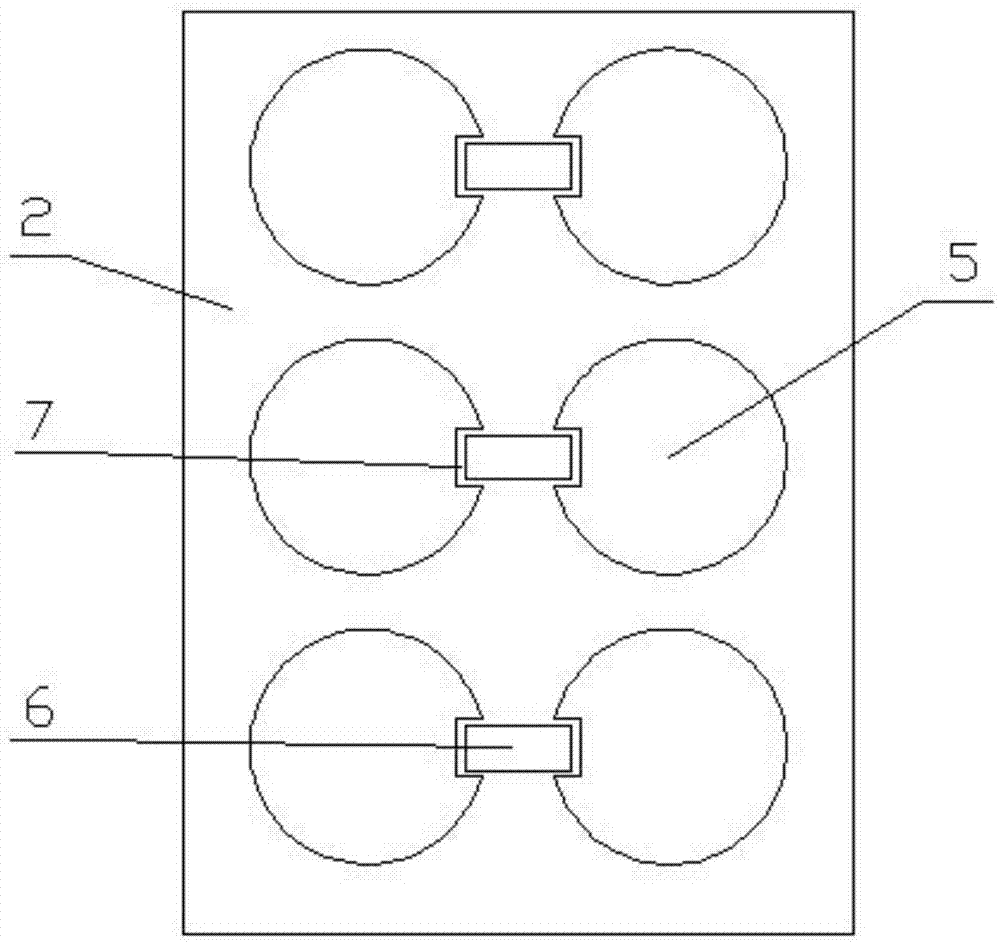

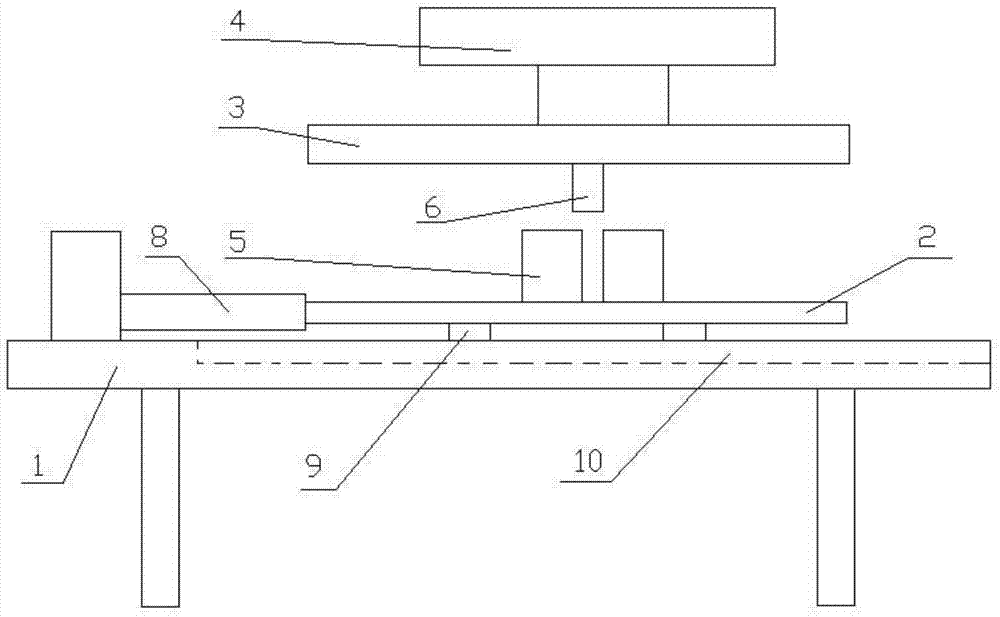

[0021] combine figure 1 , figure 2 , image 3 : A device for cutting rubber rings, related to rubber rings, including a workbench 1, a base plate 2, a pressure plate 3, a driving device 4, a plurality of columns 5, a plurality of blades 6, a hydraulic cylinder 8, and the base plate 2 is placed on the workbench 1 surface, cylinders 5 are arranged on the bottom plate 2, each cylinder 5 is provided with a groove 7 along the axial direction, the length of the groove 7 is not less than the height of the rubber ring, and the width of the groove 7 is not less than the blade 6 The thickness of the cylinder 5 is equal to the inner diameter of the rubber ring; the pressure plate 3 is placed above the bottom plate 2, the blade 6 is installed on the bottom of the pressure plate 3, the blade 6 is placed above the groove 7, the output of the pressure plate 3 and the drive device 4 end connection.

[0022] Put the rubber ring on the cylinder, push the pressure plate to move downward thro...

Embodiment 2

[0028] combine figure 1 , Figure 4 , Figure 5 : A device for cutting rubber rings, related to rubber rings, including a workbench 1, a base plate 2, a pressure plate 3, a driving device 4, a plurality of columns 5, a plurality of blades 6, a hydraulic cylinder 8, and the base plate 2 is placed on the workbench 1 surface, cylinders 5 are arranged on the bottom plate 2, each cylinder 5 is provided with a groove 7 along the axial direction, the length of the groove 7 is not less than the height of the rubber ring, and the width of the groove 7 is not less than the blade 6 The thickness of the cylinder 5 is equal to the inner diameter of the rubber ring; the pressure plate 3 is placed above the bottom plate 2, the blade 6 is installed on the bottom of the pressure plate 3, the blade 6 is placed above the groove 7, the output of the pressure plate 3 and the drive device 4 end connection.

[0029] Put the rubber ring on the cylinder, push the pressure plate to move downward thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com