Infant and child training pants shaping derice and shaping method

A composite device and training pants technology, which is applied to baby underwear, clothing, clothing, etc., to achieve low energy consumption, good skin and body comfort, and full of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

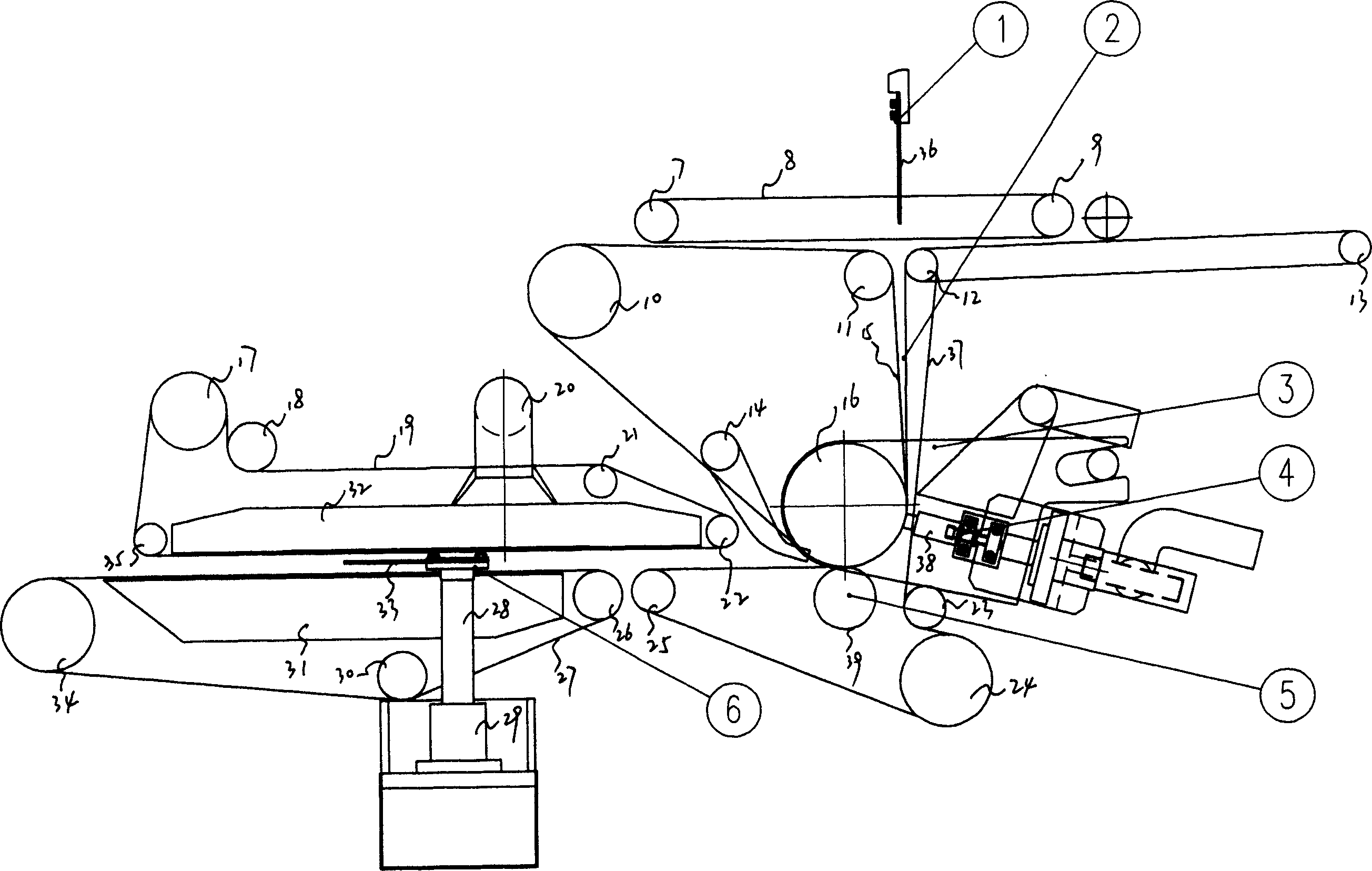

[0019] Embodiment 1: with reference to attached figure 1. The composite device for forming infant training pants is composed of a discount mechanism, a finishing mechanism, a welding mechanism, a follow-up mechanism, an edge trimming mechanism and an edge closing mechanism. After the welding mechanism is welded, the edge is trimmed by the edge trimming mechanism, and the edge is closed by the edge receiving mechanism. Folding mechanism 1 is made of plate 36, external eccentric power mechanism, guide pulley 7 and 9 and belt 8, and the transmission mechanism that guide pulley and belt constitute is used for conveying infant training pants. Insert plate 36 inserts the infant training trousers downwards from its center under the effect of the external eccentric power mechanism, so that the training trousers are folded in half and transported to the finishing mechanism 2; 11, 12, 13, 15, drive wheel 24, guide wheel 25 and belt 37 constitute, purpose forces the left and right wais...

Embodiment 2

[0020] Embodiment 2: Composite molding method of infant training pants, as described in claims 1 and 2, the inserting plate in the folding mechanism inserts the infant training pants downwards from its center so that the training pants are folded in half and transported to the finishing mechanism, and the finishing mechanism The waists on both sides of the infant training pants are smoothed, and the pattern die wheel or die roller in the welding mechanism is matched with the ultrasonic die head. When the gap is formed, the ultrasonic waves emitted by the ultrasonic die head will cause the molecular vibration between the material of the raised part of the pattern and the contact surface of the material to generate heat energy, so that the two layers of materials will be rolled and compounded by the raised part of the patterned die wheel, and the two layers of the infant training pants will be formed. The side waist piece is welded, and the two follower plates in the follow-up me...

Embodiment 3

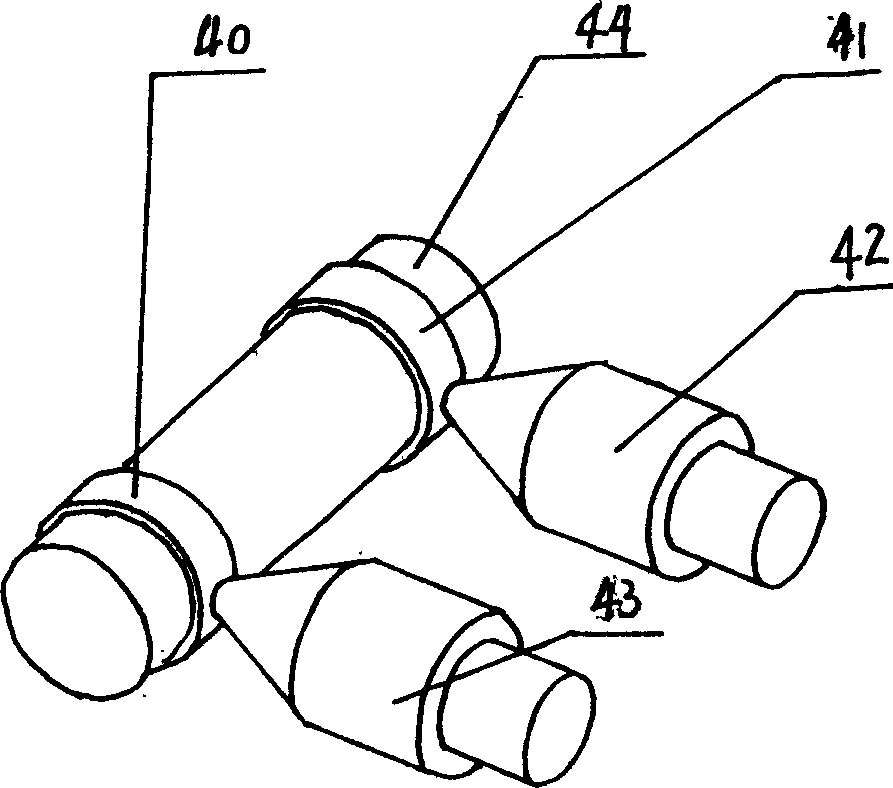

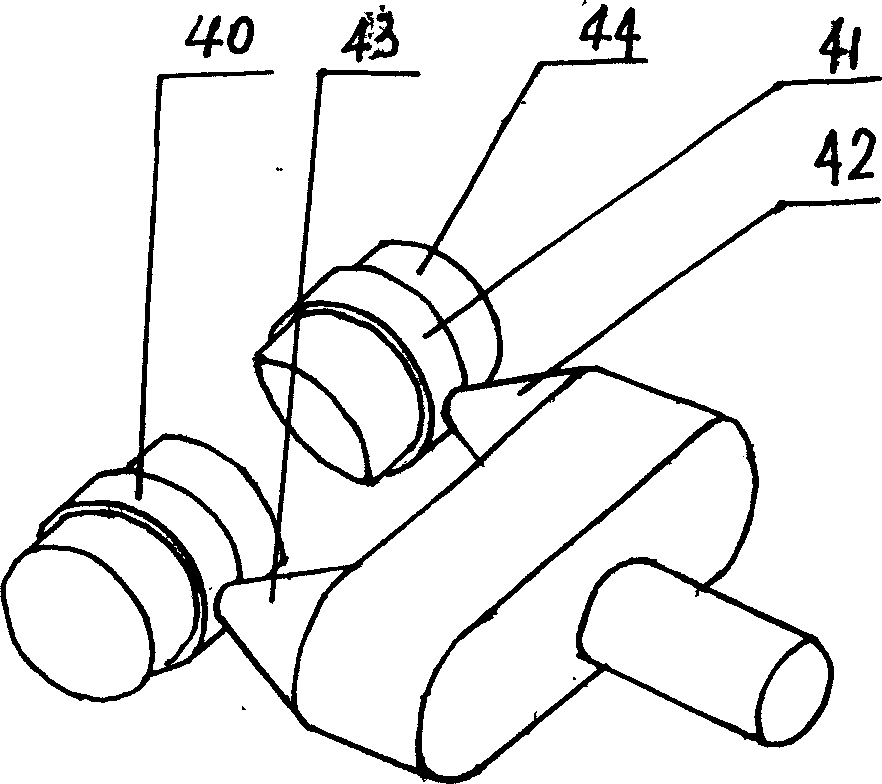

[0021] Embodiment 3: with reference to attached figure 2 . In the left and right waist piece bonding device of the infant training trousers production line, the left and right pattern mold wheels 40 and 41 are driven to rotate by coaxial (or roller) or non-axial 44 (roller) forces. This driving mechanism is a prior art (such as the present application The power drive mechanism in the production line of sanitary napkins produced by human beings). Therefore, it will not be described here. The ultrasonic heads 42 and 43 of the ultrasonic generator correspond to the points or lines of the pattern mold wheels 40 and 41, and the gap is -0.03 or -0.02 or -0.01 or 0.00 or +0.01 or +0.02 or +0.03 or or +0.04 or +0.05 or +0.06 or +0.07 or +0.08 or +0.09 or +0.10 or +0.11 or +0.12 or +0.13 or +0.14 or +0.15 or +0.16 or +0.17 or +0.18 or +0.19 or +0.20 or +0.21 Or +0.22 or +0.23 or +0.24 or +0.25mm. The ultrasonic generators are two single-head ultrasonic generators, and the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com