Sweet-scented osmanthus cake molding machine

A molding machine and pastry technology, applied in the field of sweet-scented osmanthus pastry molding machines, can solve problems such as unhygienic and complicated operation, and achieve the effect of improving efficiency and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

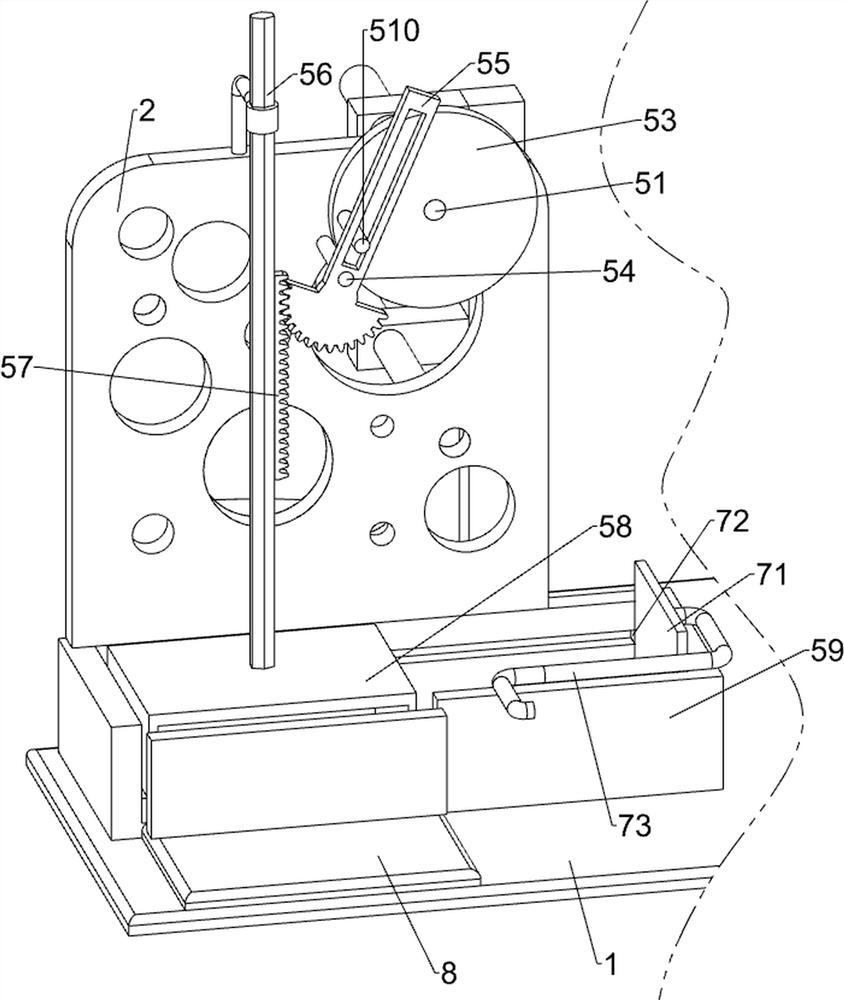

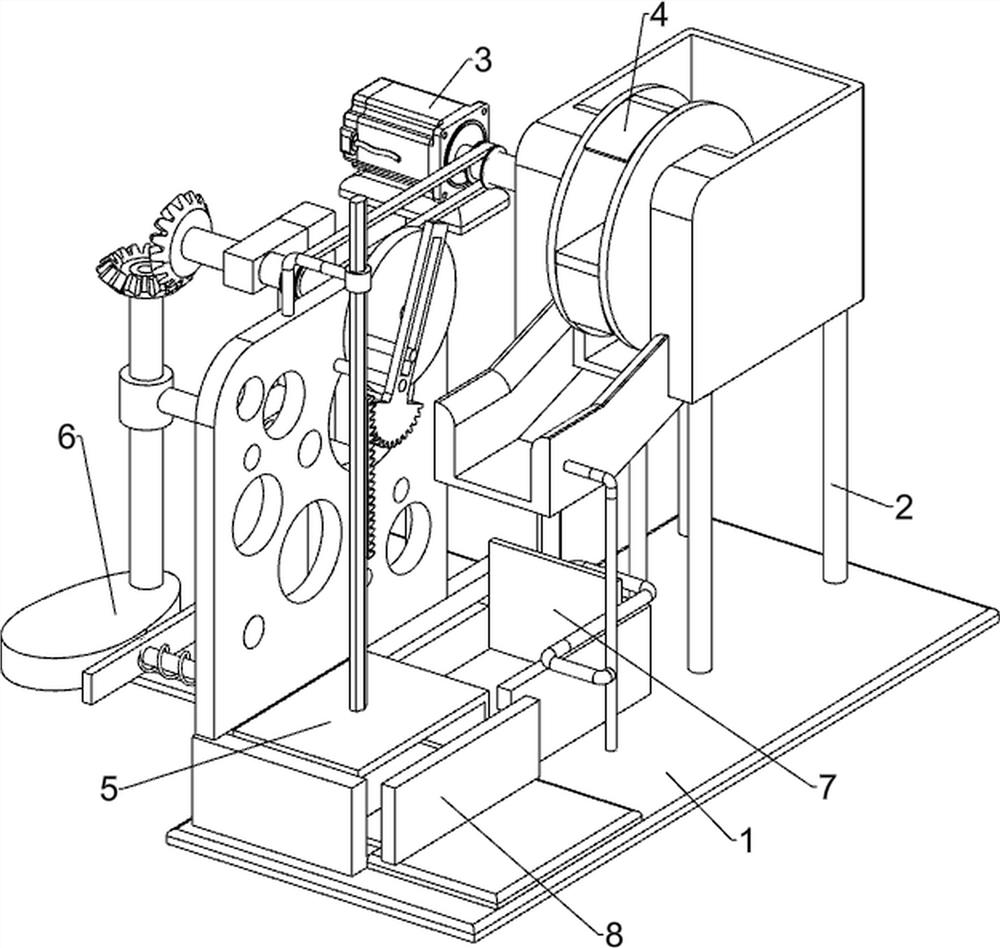

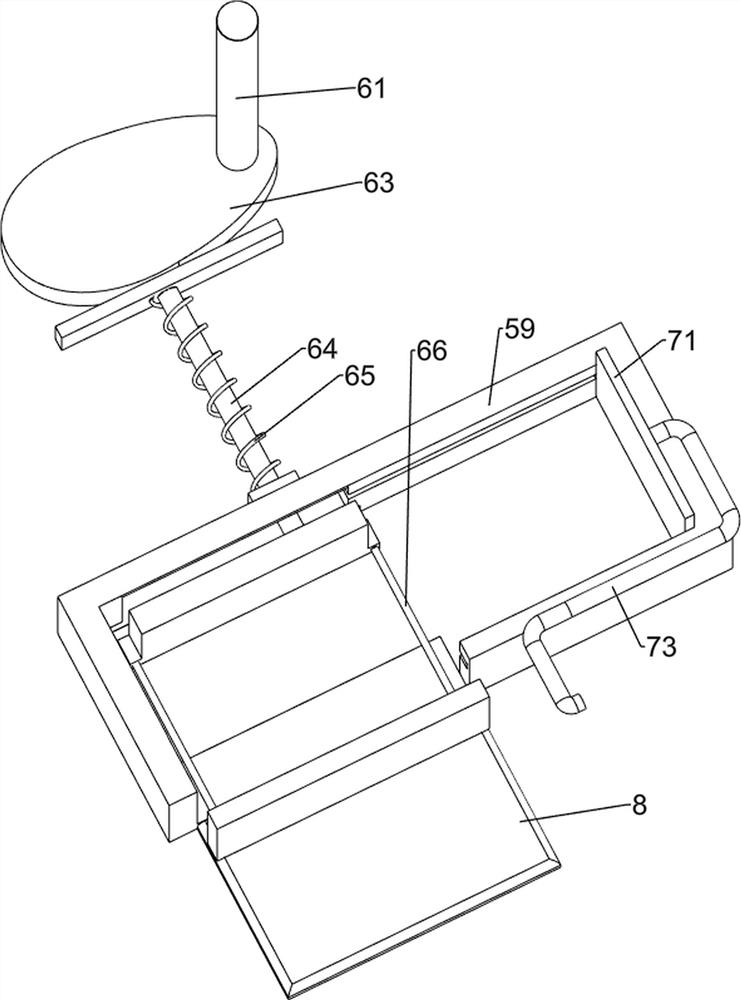

[0023] A molding machine for osmanthus pastry, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base plate 1, a support frame 2, a motor 3, a feeding mechanism 4, an extrusion mechanism 5 and a material pushing mechanism 6, the base plate 1 is provided with a support frame 2, and the support frame 2 on the left side of the upper rear part of the base plate 1 A motor 3 is installed on the bottom plate 1, and a feeding mechanism 4 is provided on the support frame 2 at the upper rear of the bottom plate 1. The output shaft of the motor 3 is connected with the feeding mechanism 4. The output shaft of the output shaft is connected with the extruding mechanism 5, and the upper left part front side of the bottom plate 1 is provided with a pushing mechanism 6, and the pushing mechanism 6 cooperates with the extruding mechanism 5.

[0024] When people prepare to make sweet-scented osmanthus cake, first raw material is poured in the feeding mechanism 4, s...

Embodiment 2

[0032] On the basis of Example 1, such as image 3 and Figure 4 As shown, a scraper mechanism 7 is also included, and the scraper mechanism 7 includes a scraper 71, a slider 72 and a second pull rod 73, and the left and right sides of the inside of the storage box 59 are slidably connected with the slider 72, and the left and right sides A scraper 71 is arranged between the sliders 72, and a second pull rod 73 is arranged at the rear of the scraper 71.

[0033] After the raw material knife was put into the holding box 43, the motor 3 was started, and now the feeding wheel 42 rotated to drive the sweet-scented osmanthus cake raw material to fall into the storage box 59. The scraper 71 moves forward. At this time, the scraper 71 will push the raw materials in the material storage box 59 to the extrusion block 58. After pushing, people manually pull the second pull rod 73, and the second pull rod 73 will drive the scraper. 71 moves backward, and when the scraper 71 returns to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com