Plate alignment adhesive for surface plate lamination of engineered wood flooring and preparation method thereof

A technology of splicing glue and mixture, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor initial strength and poor water resistance of adhesives, and achieve the improvement of initial strength and water resistance, application simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

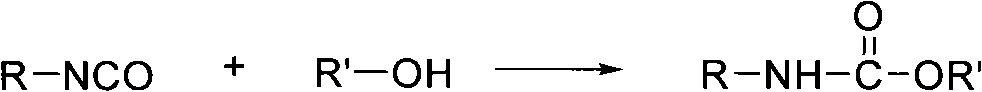

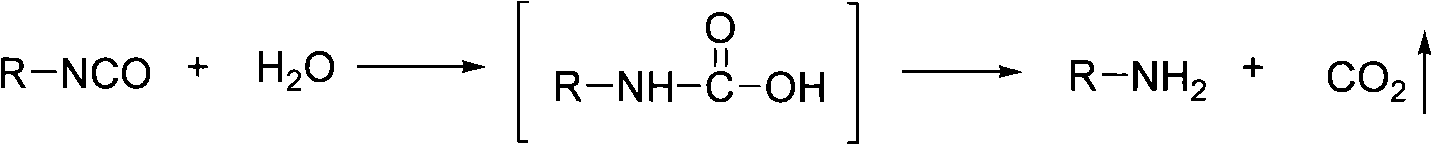

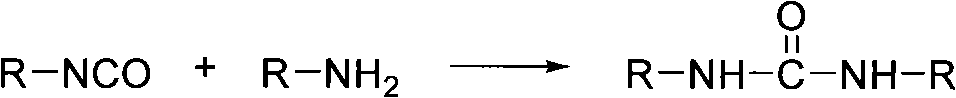

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of the jigsaw glue of the present invention is accomplished through two steps, specifically:

[0073] 1) Dissolve acrylic acid, butyl acrylate, hydroxyethyl acrylate, vinyl acetate, silane and ammonium persulfate in water, and mix them uniformly to obtain emulsified mixed monomers.

[0074] Dissolve polyvinyl alcohol in water, add an emulsifier, then heat the resulting mixture, then add the above-mentioned emulsified mixed monomers into it and mix evenly, carry out emulsion polymerization to obtain the main rubber emulsion, then add inorganic fillers, and use a 80-100 mesh filter to Filter to obtain the main ingredient;

[0075] 2) Before use, mix the main agent and curing agent obtained in step 1) evenly according to the stated ratio.

[0076] Wherein, the emulsion polymerization reaction is carried out in a stainless steel jacketed reaction kettle provided with a heat exchanger; the temperature of the emulsion polymerization reaction is 70-85° ...

Embodiment 1

[0081] Mix 100g of the main ingredient and 15g of MDI evenly, and the main ingredient is composed of the following raw materials:

[0082] Polyvinyl alcohol 4g;

[0083] Acrylic acid 1g;

[0084] Butyl acrylate 10g;

[0085] Hydroxyethyl acrylate 6g;

[0086] Vinyl acetate 20g;

[0087] Vinyltrimethoxysilane 1g;

[0088] RS-610 0.5g;

[0089] Ammonium persulfate 0.06g;

[0091] Heavy calcium 10g;

[0092] Deionized water 42.44g.

[0093] Among them, polyvinyl alcohol is PVA1788 produced by Beijing Organic Chemical Factory, its degree of polymerization is 1700, and its degree of alcoholysis is 87. RS-610 is purchased from Rhodia Company, and other raw materials are commercially available.

[0094] The preparation method is specifically:

[0095] Step 1: Mix 30g of water, 1g of acrylic acid, 10g of butyl acrylate, 6g of hydroxyethyl acrylate, 20g of vinyl acetate, 1g of vinyltrimethoxysilane and 0.06g of ammonium persulfate to obtain an emulsif...

Embodiment 2

[0101] Mix 100g of main ingredient and 15g of TDI evenly, and the main ingredient is composed of the following raw materials:

[0102] Polyvinyl alcohol 5g;

[0103] Acrylic acid 1.5g;

[0104] Butyl acrylate 10g;

[0105] Hydroxyethyl acrylate 6g;

[0106] Vinyl acetate 18g;

[0107] Vinyltriethoxysilane 1.5g;

[0108] RS-610 0.5g;

[0109] Ammonium persulfate 0.06g;

[0110] Heavy calcium 15g;

[0111] Deionized water 42.44g;

[0112] Among them, polyvinyl alcohol is PVA1788 produced by Beijing Organic Chemical Factory, its degree of polymerization is 2400, alcoholysis degree is 89, RS-610 is purchased from Rhodia Company, and other raw materials are commercially available.

[0113] The preparation method is specifically:

[0114] Step 1: Mix 30g of water, acrylic acid, butyl acrylate, hydroxyethyl acrylate, vinyl acetate, vinyltriethoxysilane, and ammonium persulfate to obtain emulsified mixed monomers.

[0115] Step 2: Heat 12.44g of water to 80°C to dissolve pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com