Metal organic framework/wood composite material, and preparation method and application thereof

A metal-organic framework and composite material technology, which is applied in the field of metal-organic framework/wood composite materials and their preparation, and can solve the problems of the preparation process and poor binding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

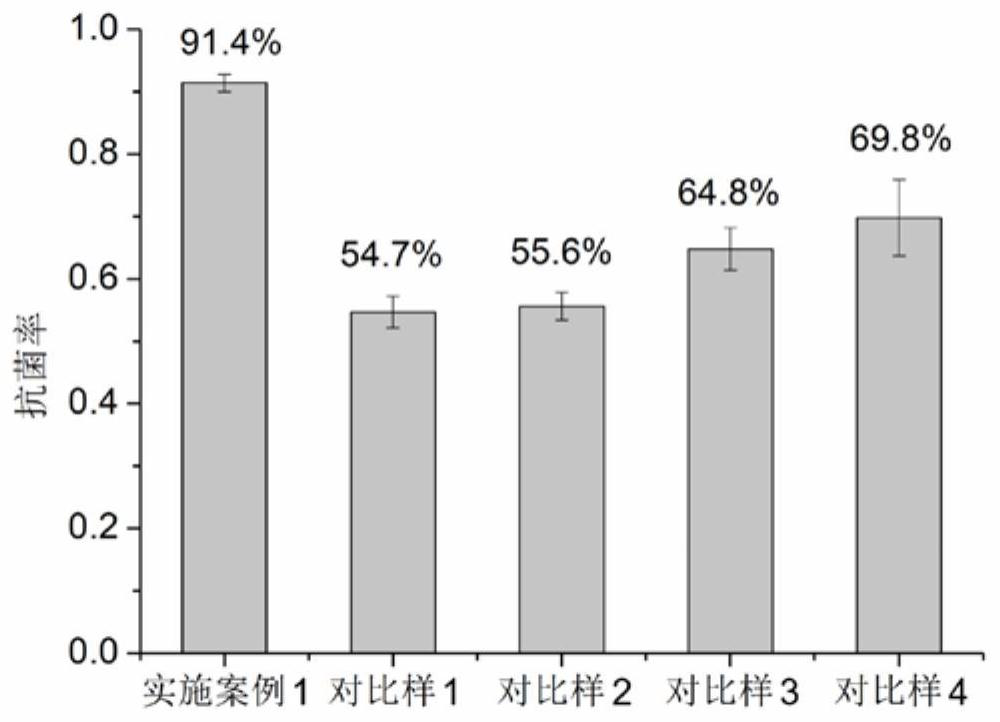

Examples

Embodiment 1

[0063] (1) Soak the three-year-old Moso bamboo block (L×T×R=20cm×25mm×6mm) in sodium chlorite (NaClO 2 , 80%) solution, the solution was adjusted to pH 4.6 with acetic acid, heated in a water bath (100° C.) for 1 h, and finally the bamboo pieces were washed with deionized water, and vacuum-dried for later use.

[0064] (2) The delignified bamboo pieces were placed in 1 mol / L sodium hydroxide solution and kept at room temperature for 30 minutes, then the samples were taken out and soaked in 1 mol / L sodium chloroacetate solution and kept at room temperature for 30 minutes. Finally, the sample was soaked in 2 g / L acetic acid solution for 10 min, washed with deionized water and dried to obtain pretreated bamboo pieces.

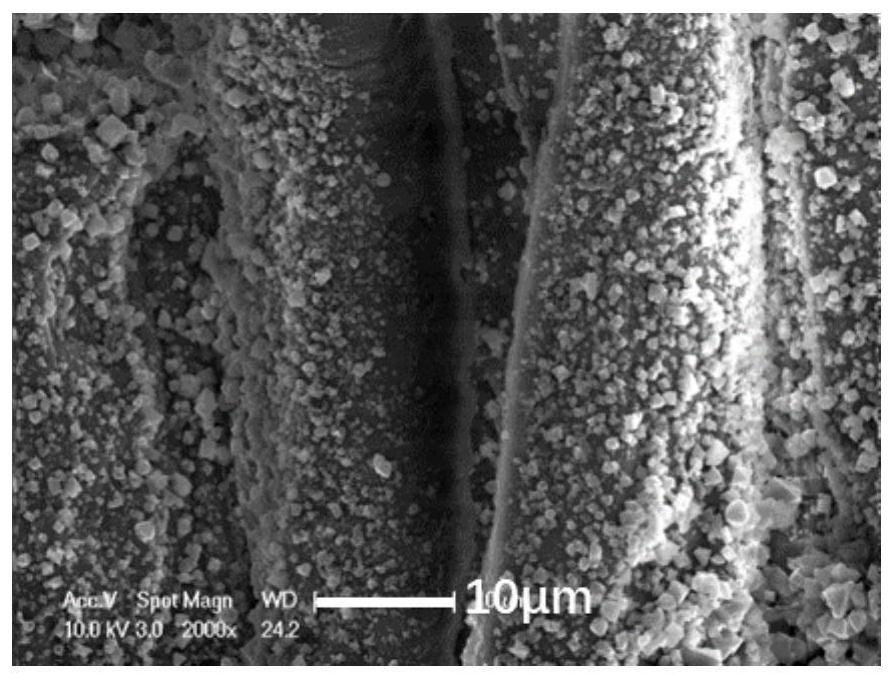

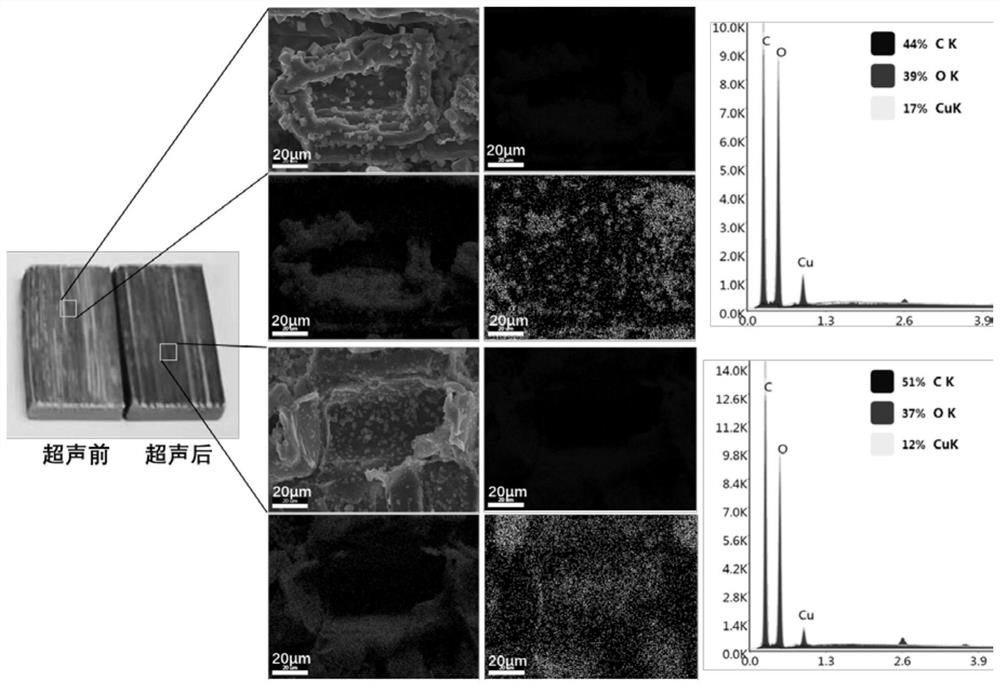

[0065] (3) soak the pretreated bamboo pieces obtained above in a mixed solution of copper nitrate (0.3mol / L) and DMF, ethanol, water (V:V:V=1:1:1), soak at room temperature for 12 hours, remove and drain excess liquid on the surface for later use.

[0066] (4) P...

Embodiment 2

[0071] (1) Soak balsa wood (L×T×R=10mm×10mm×10mm) in a 2% mass fraction of sodium chlorite solution (pH=4.6), heat in a water bath at 100°C for 6 hours, and the sodium chlorite The solution was replaced every 2 hours, and after taking it out, it was cleaned with a mixed solution of ethanol and water, and dried for 6 hours for later use.

[0072] (2) Put the delignified wood block in 1mol / L sodium hydroxide solution, keep it at room temperature for 30min, then take out the sample and soak it in 1mol / L sodium chloroacetate solution, keep it at room temperature for 30min. Finally, the sample was soaked in 2 g / L acetic acid solution for 10 min, washed with deionized water and dried to obtain the pretreated wood block.

[0073] (3) Soak the pretreated wood blocks obtained above in a mixed solution of copper chloride (0.3mol / L) and DMF, methanol, water (V:V:V=1:1:1), soak at room temperature and keep After 12 hours, take out and drain the excess liquid on the surface for later use....

Embodiment 3

[0077] By adjusting the concentration of the metal salt solution, the controllable growth of MOF199 on the surface of the pretreated bamboo is realized, and the specific steps are as follows:

[0078] (1) Dissolve 0.075, 0.15, 0.3, 0.6mol / L copper nitrate trihydrate in 250ml mixed solvent solution of DMF / ethanol / water (V:V:V=1:1:1) respectively to prepare different concentrations of copper solution.

[0079] (2) Subsequently, 10.417 g of trimesic acid was dissolved in 250 ml of a mixed solution of DMF / ethanol / water (V:V:V=1:1:1) to prepare an organic ligand solution.

[0080] (3) Bamboo pieces treated according to steps (1) and (2) of Example 1 for delignification and carboxylation were soaked in copper nitrate trihydrate solutions of four concentrations for 12 hours.

[0081] (4) Take out the four samples respectively, drain them, place them in the trimesic acid solution, continue to stir for 24 hours, take them out and wash them with absolute ethanol and deionized water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com