Magnesium alloy artificial limb connector and manufacturing method thereof

A manufacturing method and a technology of a connecting head, which are applied in the field of prosthetics, can solve the problem that the comprehensive performance of the connecting head of the prosthesis cannot meet the requirements, etc., and achieve the effect of reducing the processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

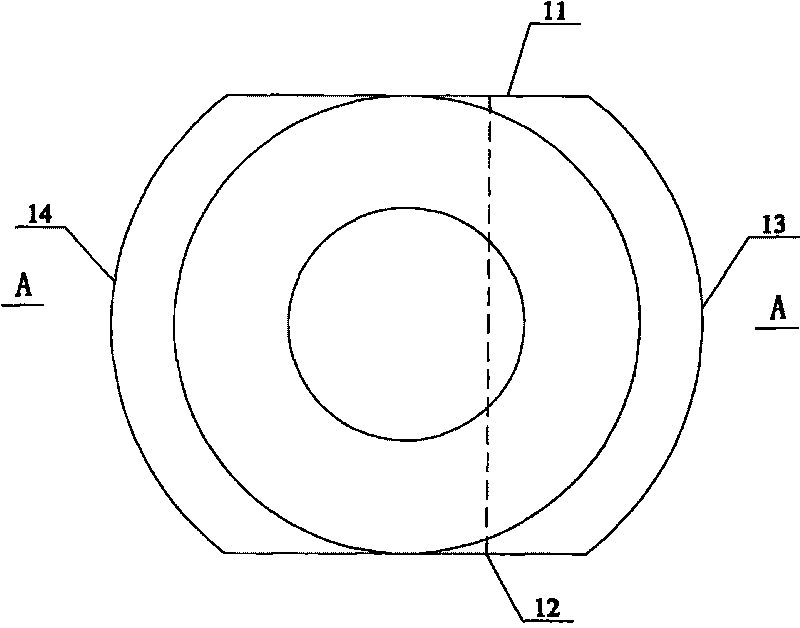

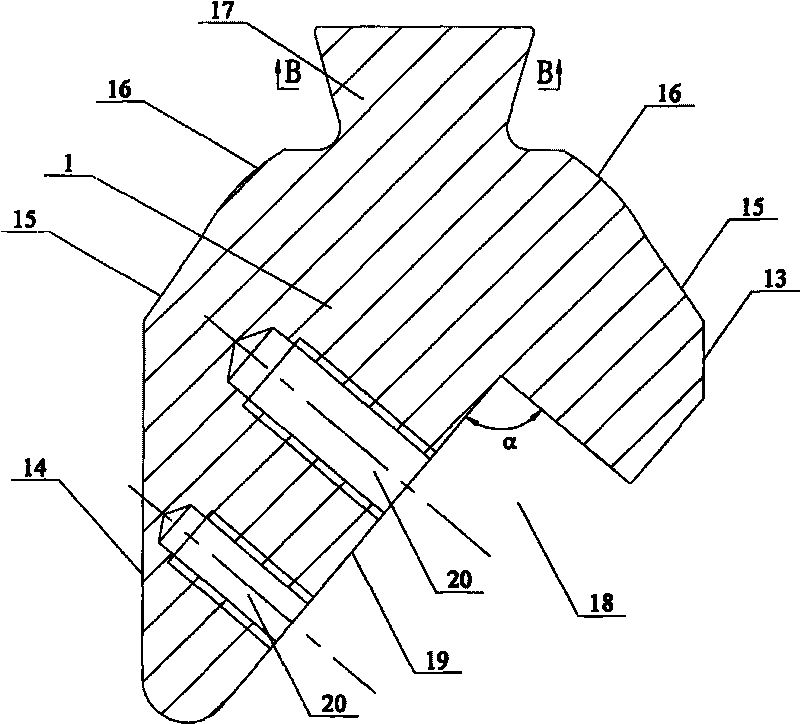

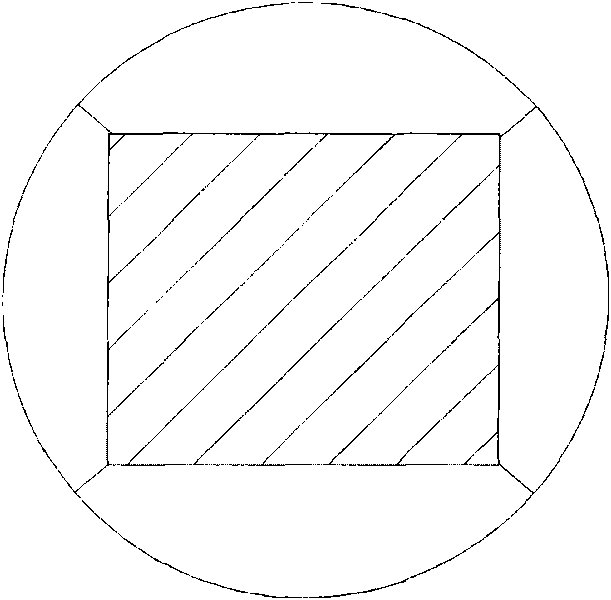

[0027] figure 1 is the top view of the prosthetic connection head, figure 2 for figure 1 The A-A profile in, such as figure 1 , figure 2 As shown, the prosthesis connector has a columnar body 1, the columnar body 1 has two parallel sides 11, 12, the lower parts 13, 14 of the other two sides of the columnar body 1 are cylindrical surfaces, and the middle part is small at the top and large at the bottom. The conical surface 15, the top is an arc surface 16, the upper surface of the columnar body 1 is provided with a four-sided truss 17 with a large upper part and a lower one, and the top of the four-sided truss 17 is cylindrical (see image 3 ), the bottom surface of the columnar body 1 is provided with a triangular wedge-shaped groove 18, and the apex angle α of the wedge-shaped groove 18 is 90 degrees. Two threaded connection holes 20 are drilled on the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com