Closing device of connector jack

A closing device and connector technology, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problem of not being able to guarantee the closing accuracy and plugging and contact performance, affecting the performance of the electrical connector, and not being able to ensure the overall concentricity And other problems, to achieve the effect of ensuring concentricity and plugging performance, high precision, and high concentricity of the closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

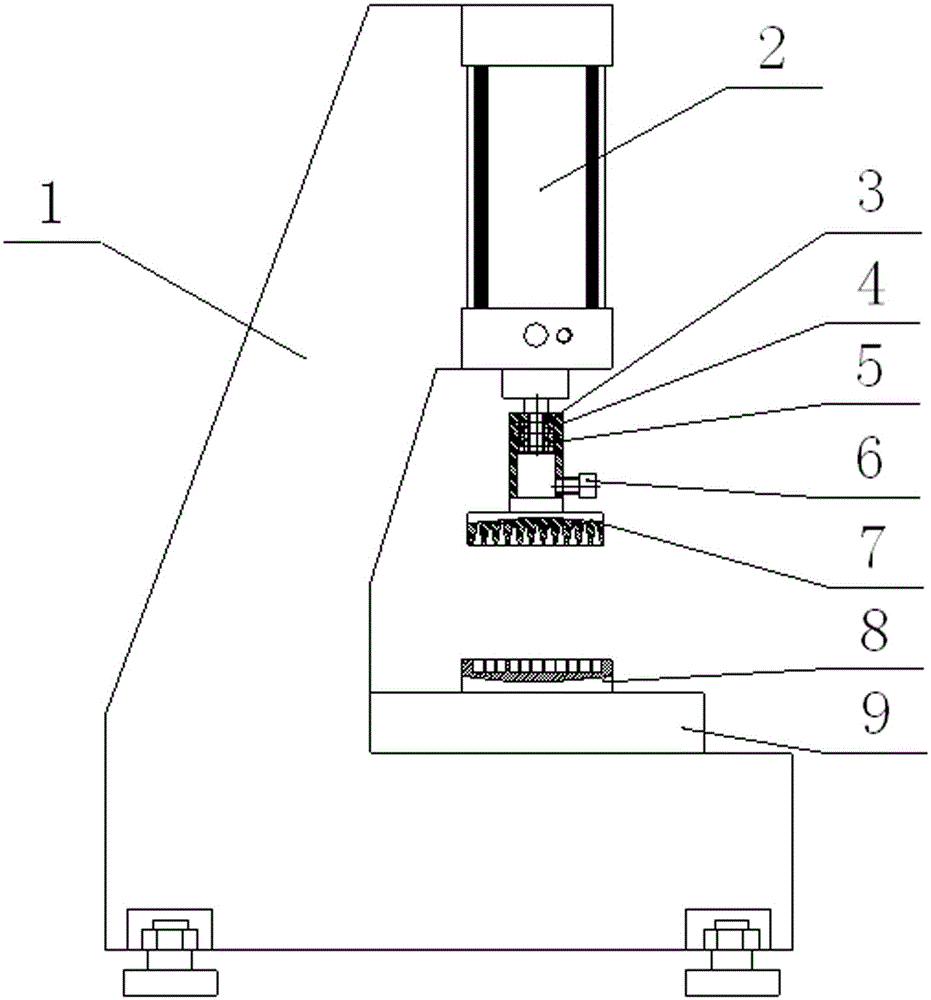

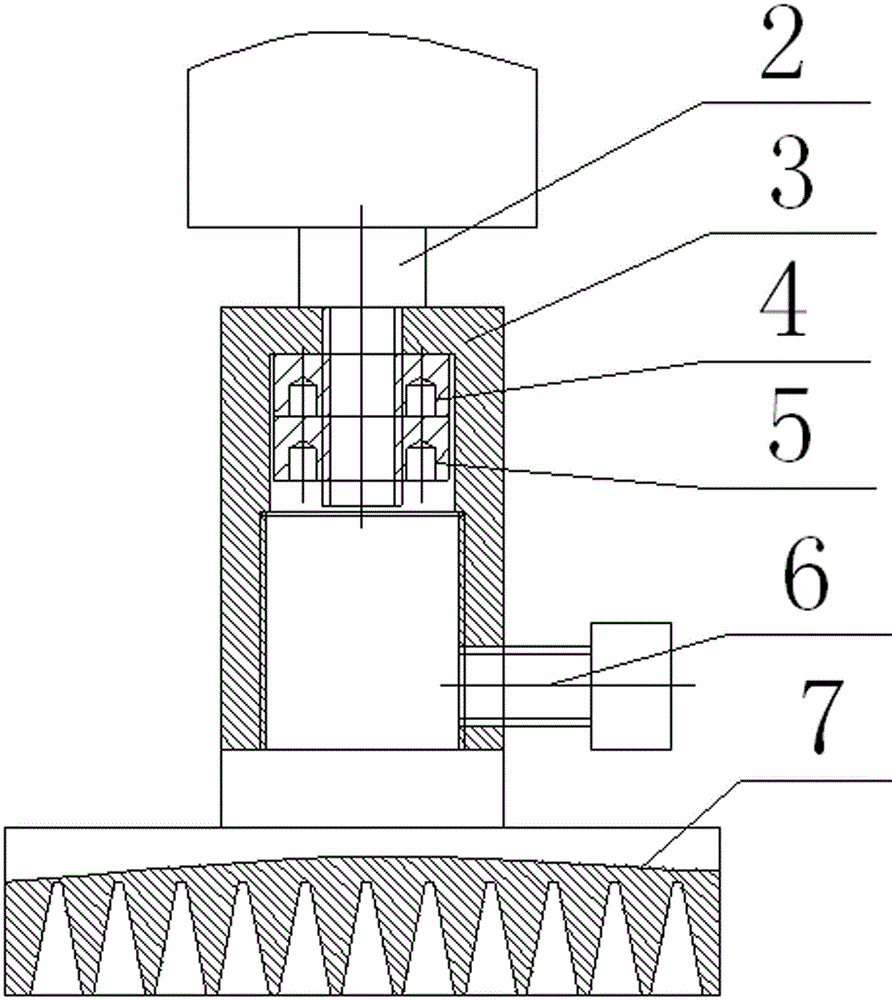

[0013] figure 1 , 2 As shown: a closing device for a connector jack includes a body 1, a pneumatic device 2, a fixing sleeve 3, a fixing nut 4, a stop nut 5, a set screw 6, a closing plate 7, a positioning fixture 8 and a workbench 9 . The pneumatic device 2 and the workbench 9 are respectively fixed on the fuselage 1 up and down, and the fixing sleeve 3 is tightly and fixedly connected to the bottom of the pneumatic device 2 through the fixing nut 4 and the stop nut 5 . The closing disc 7 is threadedly connected with the fixing sleeve 3, and the set screw 6 locks it. The positioning jig 8 is mounted on the workbench 9 corresponding to the closing disc 7 and is detachable.

[0014] The pneumatic device 2 pushes the closing disc 7 to move and return to the positioning fixture 8, thereby closing the socket of the electrical connector. The closing disc 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com