Method for repairing corner of locating pin of bearing case

A technology of bearing casing and locating pin is applied in the field of aero-engine to achieve the effects of low processing difficulty, cost saving and simple repair operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

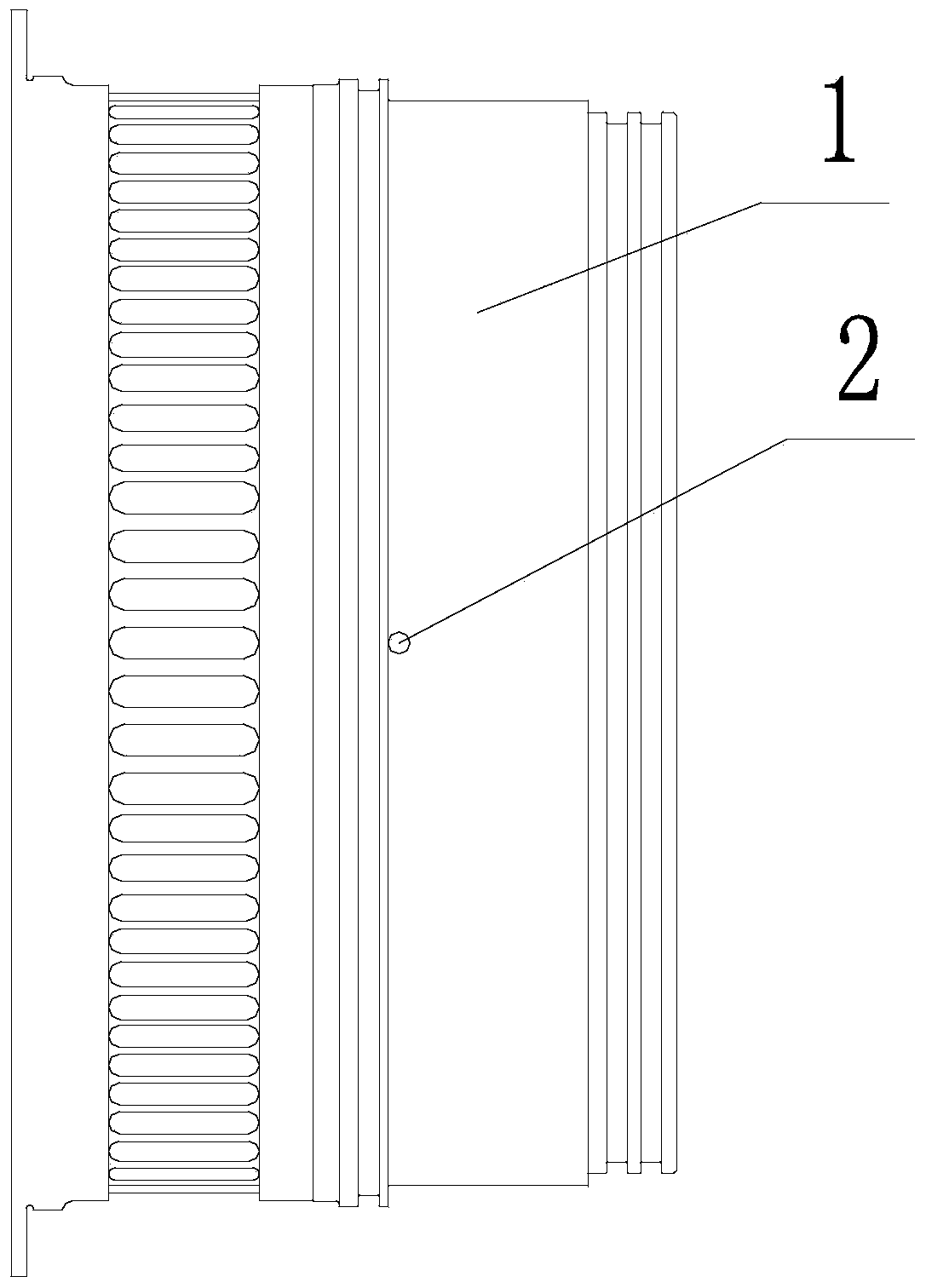

[0018] Repair the structure of the positioning pin part of the front bearing casing, such as figure 1 As shown, the bearing case is repaired by adopting the method for repairing the positioning pin angle of the bearing case of the present invention, which specifically includes the following steps:

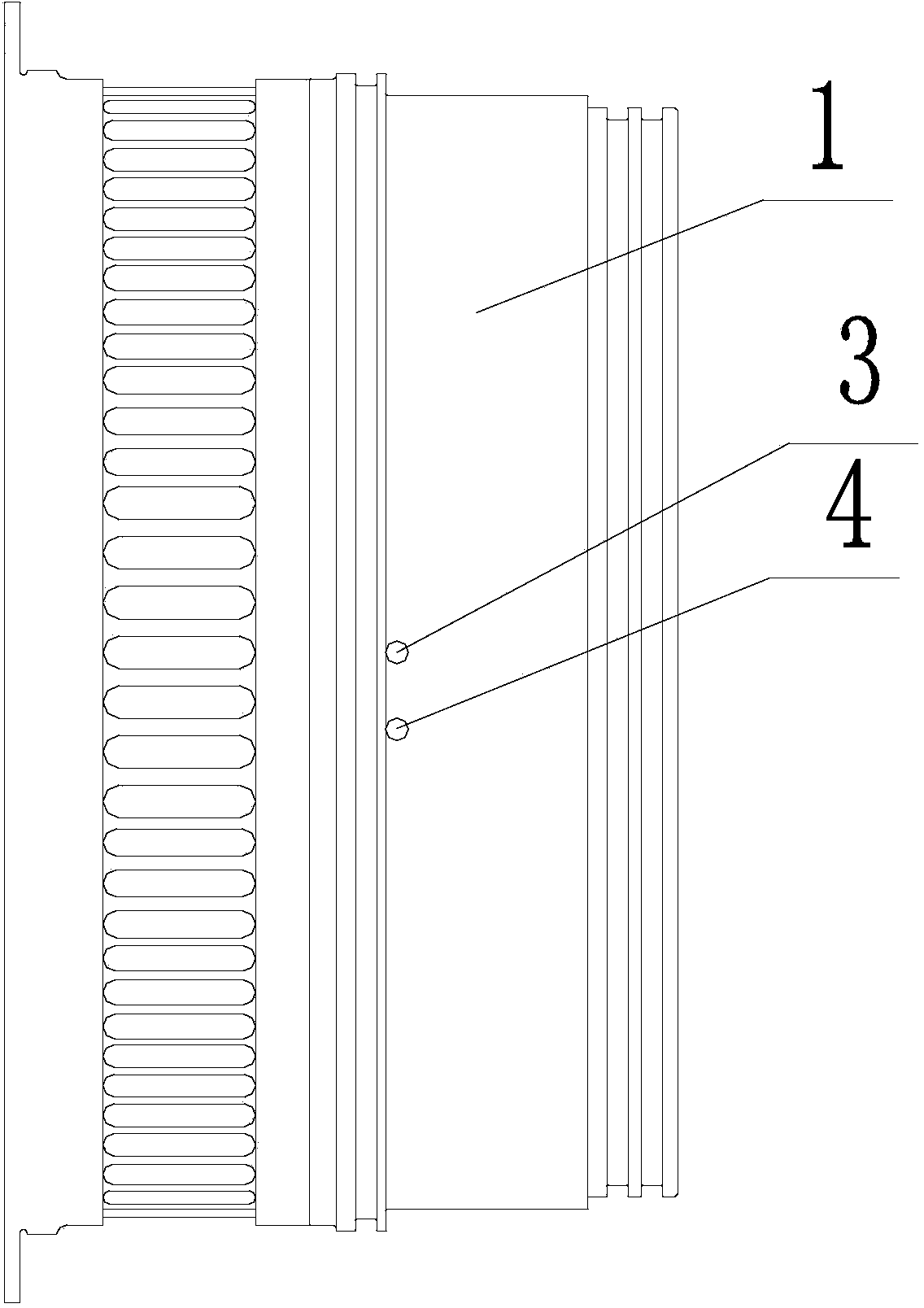

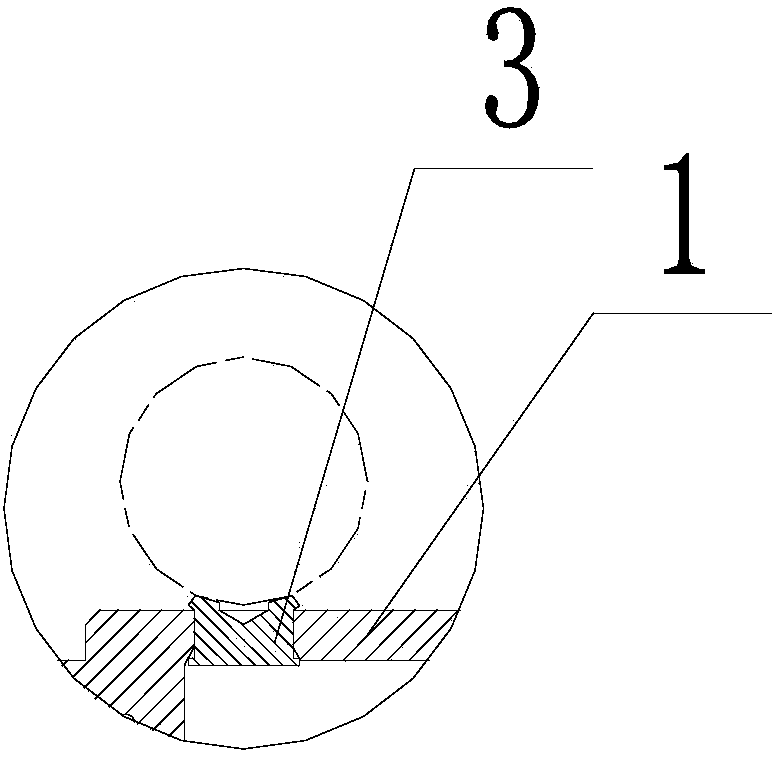

[0019] Step 1: processing the plugging pin 3, which corresponds to the hole of the original positioning pin;

[0020] Step 2: Pull out the original positioning pin 2 of the bearing casing 1, align the bearing casing 1 on the machine tool and fix it, and use the original positioning pin hole as a reference, rotate the bearing casing 1 by 9° and process the new positioning pin hole , and process a 30° chamfer;

[0021] Step 3: Install the plugging pin 3 in the original positioning pin hole, and install the new positioning pin 4 in the new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com