A kind of low-viscosity and high-permeability building concrete reinforcement and plugging epoxy waterproof material and preparation method thereof

A technology of concrete reinforcement and waterproof material, which is applied in the field of low-viscosity and high-permeability building concrete reinforcement and plugging epoxy waterproof material and its preparation field, can solve the problems of concrete leakage, waterproof failure, plastic shrinkage cracks, etc. Good corrosion performance, stable structure and moderate pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

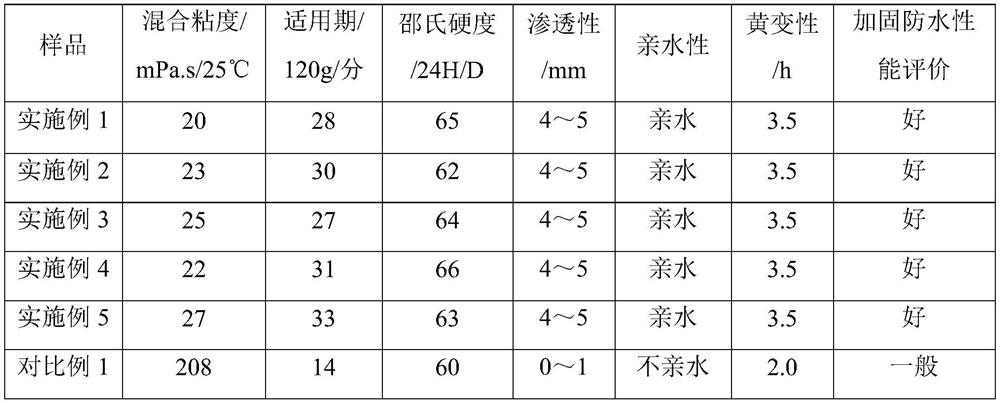

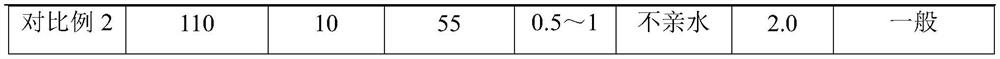

Examples

preparation example Construction

[0030] The preparation method of the modified cycloaliphatic amine curing agent adopted in each of the following embodiments comprises: adding cycloaliphatic amine curing agent PACM in the reaction vessel, adjusting the temperature to be 47~52 DEG C, dripping epoxy resin E-54 benzyl alcohol solution ( 20wt.% E-54, 80wt.% benzyl alcohol), complete in 2.0-2.5 hours, adjust the temperature to 51-56°C and continue the reaction for 1.5-2.5 hours, then filter and discharge to obtain the product;

[0031] The weight ratio of PACM to epoxy resin E-54 benzyl alcohol solution (17wt.%-23wt.% E-54, 77wt.%-83wt.% benzyl alcohol) is 6-7:1.

[0032] The preparation method of the flexible modifying agent that adopts comprises: adding 1,4-butanediol diglycidyl ether in reaction vessel, adjusting temperature is 50~55 ℃, dripping gamma-aminopropyltriethoxysilane, 1.5 ~ 2.0 hours to complete, adjust the temperature to 55 ~ 60 ° C and continue to react for 1 hour, then filter and discharge;

[00...

Embodiment 1

[0036] A low-viscosity and high-permeability building concrete reinforcement plugging epoxy waterproof material, including A component and B component;

[0037] The raw materials of component A are as follows: 45.0g bisphenol A epoxy resin E-54, 32.0g 1,4-butanediol diglycidyl ether, 14.0g flexible modifier, 3.0g KH560 and 6.0g benzyl alcohol;

[0038] The raw materials of component B are as follows: 21.0g 1,3-BAC, 40.0g modified alicyclic amine curing agent, 29.0g polyetheramine D220 and 10.0g benzyl alcohol.

[0039] A method for preparing a low-viscosity high-permeability building concrete reinforcement plugging epoxy waterproof material, comprising the steps of:

[0040] (1) Heat 45.0g of bisphenol A epoxy resin E-54 to 65-70°C, add it into the reaction flask, start stirring, add 32.0g of 1,4-butanediol diglycidyl ether, 14.0g of flexible modified agent, 3.0g KH560 and 6.0g benzyl alcohol, and stirred for 70 minutes to obtain component A.

[0041](2) Add 21.0g of 1,3-BAC...

Embodiment 2

[0053] A low-viscosity and high-permeability building concrete reinforcement plugging epoxy waterproof material, including A component and B component;

[0054] The raw materials of component A are as follows: 51.0g bisphenol A epoxy resin E-54, 20.0g 1,4-butanediol diglycidyl ether, 11.0g flexible modifier, 6.0g KH560 and 12.0g benzyl alcohol;

[0055] The raw materials of component B are as follows: 28.0g 1,3-BAC, 36.0g modified alicyclic amine curing agent, 21.0g polyetheramine D220 and 15.0g benzyl alcohol.

[0056] A method for preparing a low-viscosity high-permeability building concrete reinforcement plugging epoxy waterproof material, comprising the steps of:

[0057] (1) Heat 51.0g of bisphenol A epoxy resin E-54 to 65-70°C, add it into the reaction flask, start stirring, add 20.0g of 1,4-butanediol diglycidyl ether, 11.0g of flexible modified agent, 6.0g KH560 and 12.0g benzyl alcohol, and stirred for 70 minutes to obtain component A.

[0058] (2) Add 28.0g of 1,3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com