Novel rail vehicle fireproof coating

A technology for fire-resistant coatings and rail vehicles, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve problems such as unsuitable construction, strong odor of curing agent, sensitivity to water vapor, etc., to avoid skin allergies, avoid strong odor, and good The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

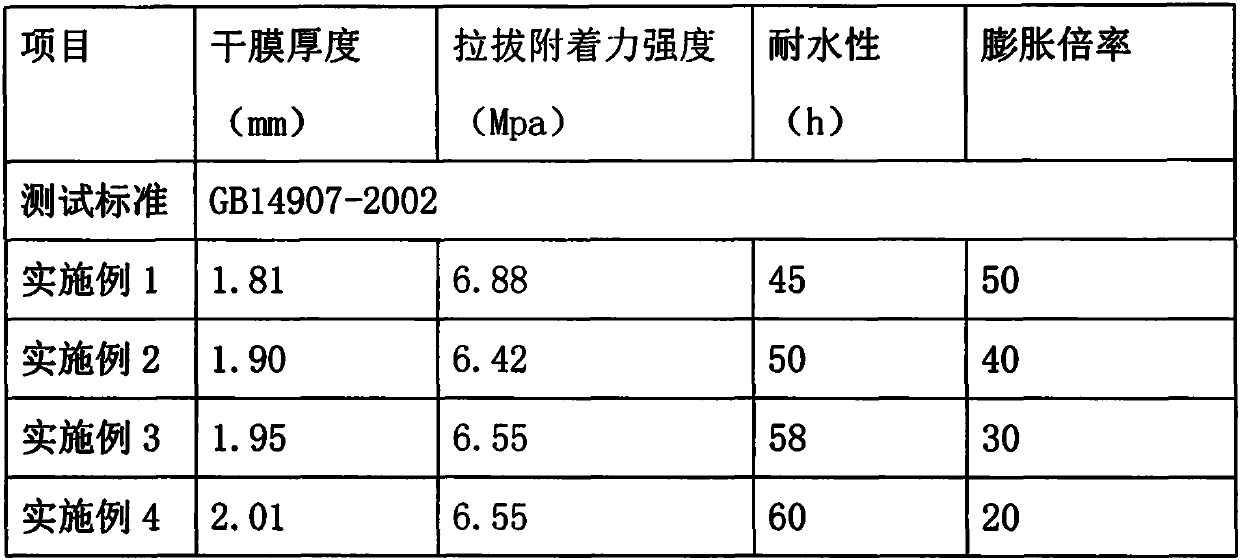

Examples

Embodiment 1

[0031] The mixing weight ratio of resin A component and curing agent B component is 3.5:1.5;

[0032] Resin A component: 30 parts of acrylic modified epoxy resin, specifically, select 60% bisphenol A epoxy resin, 20% bisphenol A ethoxy diacrylate, 10% 1,6-hexanediol Diacrylate, 10% pentaerythritol tetraacrylate, thus mixed to obtain acrylic modified epoxy resin; 28 parts of fire retardant, 11 parts of reinforcing agent, 1 part of thickening aid;

[0033] Curing agent B component: 10 parts of modified amine curing agent, 14 parts of foaming agent, 2 parts of glass fiber, 2 parts of carbon fiber, and 2 parts of ceramic fiber.

Embodiment 2

[0035] The mixing weight ratio of resin A component and curing agent B component is 3.5:1.5;

[0036] Resin A component: 35 parts of the same acrylic modified epoxy resin as in Example 1, 20 parts of flame retardant, 14 parts of reinforcing agent, and 1 part of thickening additive;

[0037] Curing agent component B: 15 parts of modified amine curing agent, 12 parts of foaming agent, 1 part of glass fiber, 1 part of carbon fiber, and 1 part of ceramic fiber.

Embodiment 3

[0039] The mixing weight ratio of resin A component and curing agent B component is 3.5:1.5;

[0040] Resin A component: 40 parts of the same acrylic modified epoxy resin as in Example 1, 15 parts of flame retardant, 13 parts of reinforcing agent, and 2 parts of thickening aid;

[0041] Curing agent B component: 18 parts of modified amine curing agent, 9 parts of foaming agent, 1 part of carbon fiber, and 2 parts of ceramic fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com