Epoxy anticorrosion primer for smooth metal surface and preparation method thereof

A metal surface, anti-corrosion primer technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of small adhesion improvement, and achieve the effects of improved solubility, excellent adhesion effect, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

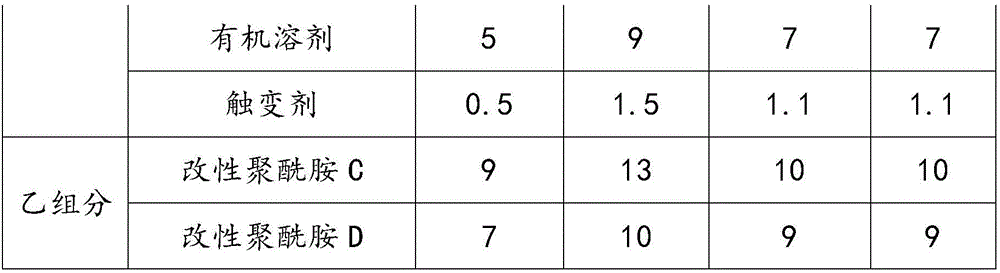

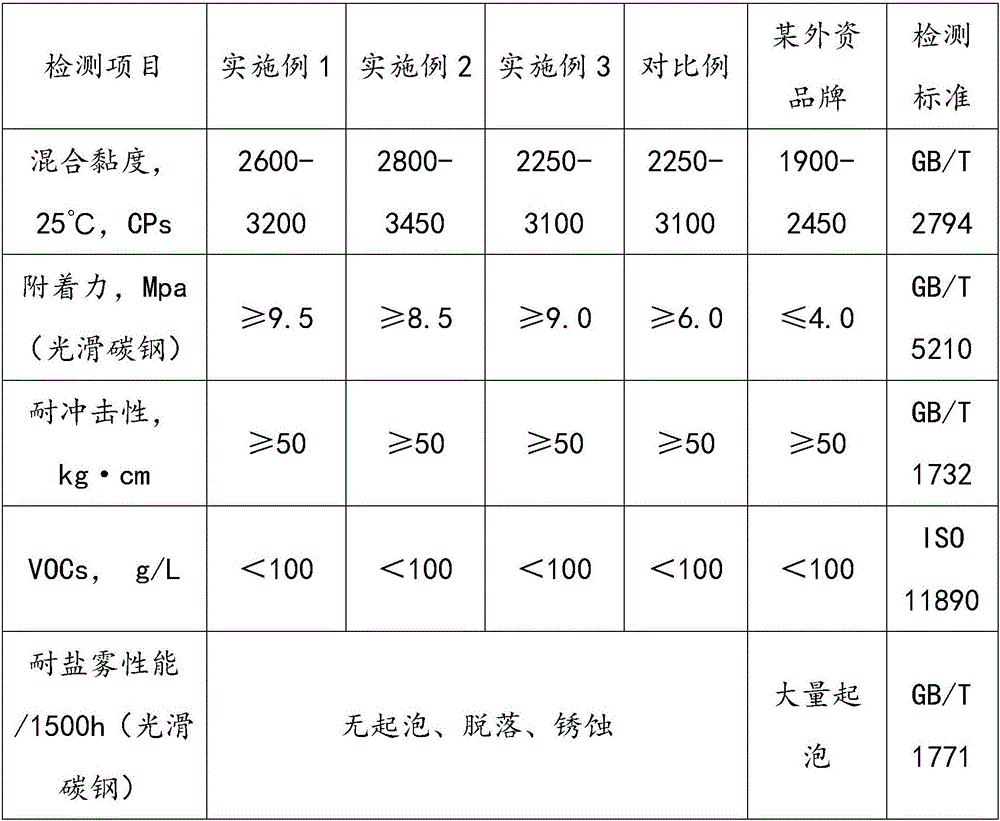

[0029] Table 1 provides 3 examples and 1 comparative example.

[0030] Table 1 Example

[0031]

[0032]

[0033] The preparation of component A in Examples 1-3 is carried out according to the preparation process flow provided by the present invention, and its specific preparation process is as follows: add diluent in the dispersion tank, mix epoxy resin E20, epoxy resin E51, aminosilane Add the coupling agent into the dispersion tank and stir evenly, the stirring line speed is 3-10m / s, after stirring for 10-20min, the temperature is raised to 70-75°C, and the temperature is kept for 25-35min to obtain the modified epoxy resin; to be mixed Add wetting and dispersing agent and defoaming agent to it when it is down to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com