Method for preparing super fine light conductive fibre

A conductive fiber, lightweight technology, applied in the direction of fiber type, fiber processing, melt spinning, etc., can solve problems such as thick diameter, achieve the effect of small filling amount, not easy to settle, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

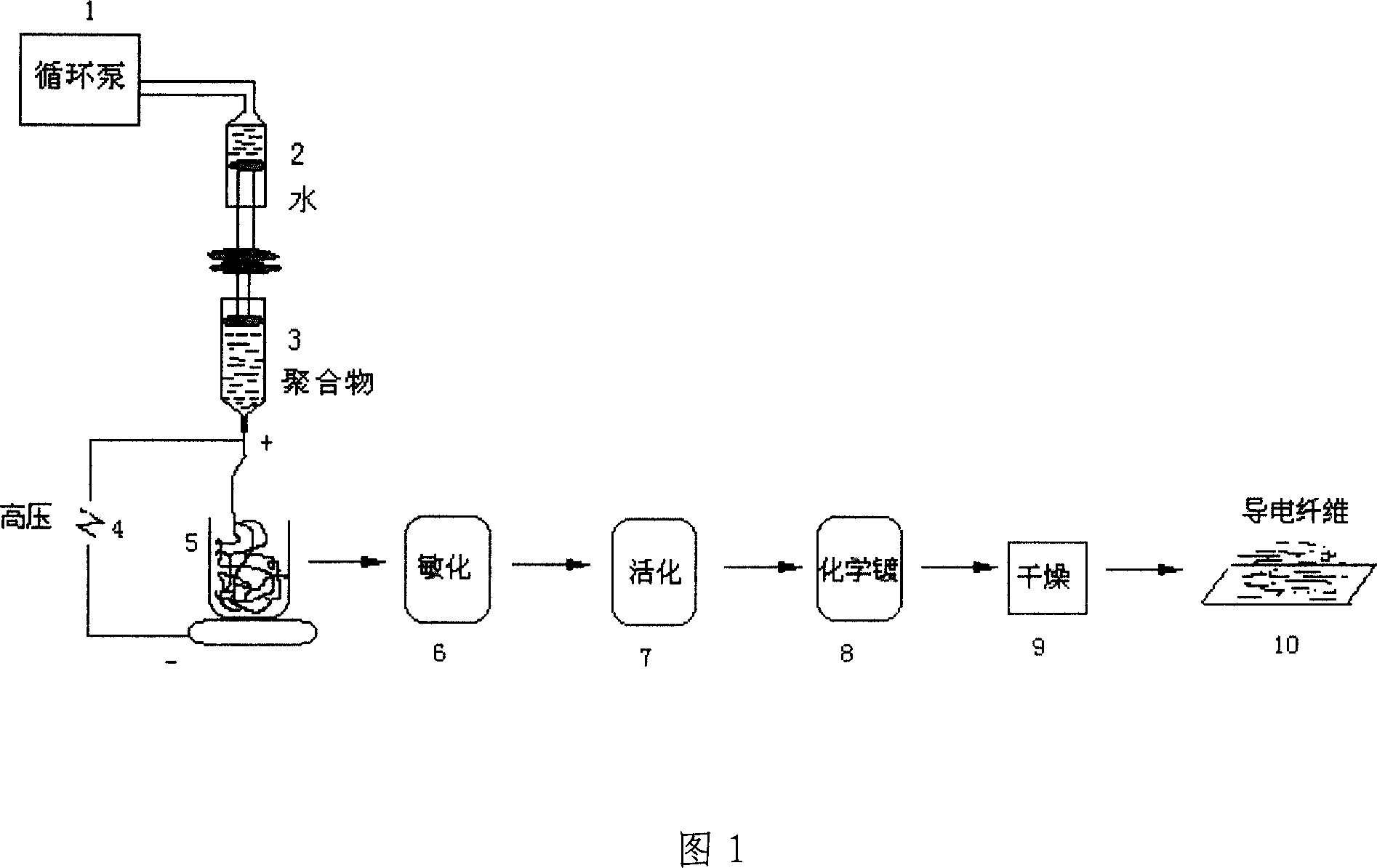

Image

Examples

Embodiment 1

[0019] Dissolve 15g of polyacrylonitrile (PAN) in 100g of dimethylformamide (DMF), and perform electrospinning at a high voltage of 10-30 kV to obtain ultrafine polyacrylonitrile fibers. After high-speed crushing and sieving, short fibers with a diameter of 0.01-1 μm and different lengths can be obtained. Sensitized by sensitizing solution (stannous chloride 10g / L, hydrochloric acid 50mL / L), activated by activation solution (palladium chloride 0.3g / L, hydrochloric acid 10g / L), and then in electroless copper plating solution (copper sulfate 10g / L) L, potassium sodium tartrate 40g / L, potassium hydroxide 20g / L, formaldehyde 15g / L) in copper plating for 30 minutes, after filtering and drying, the obtained density is 1.9g / cm 3 Copper-coated conductive fibers.

Embodiment 2

[0021] Dissolve 75g of polyacrylonitrile (PAN) in 500g of dimethylformamide (DMF), and perform electrospinning at a high voltage of 10-30 kV to obtain ultrafine polyacrylonitrile fibers. After high-speed crushing and sieving, short fibers with a diameter of 0.01-1 μm and different lengths can be obtained. Sensitized by sensitizing solution (stannous chloride 10g / L, hydrochloric acid 50mL / L), activated by activation solution (palladium chloride 0.3g / L, hydrochloric acid 10g / L), and then in electroless silver plating solution (silver nitrate 5g / L) L, potassium hydroxide 2g / L, invert sugar 0.7g / L) silver-plated in 5 minutes, through filtering and drying, namely obtain density is 2g / cm 3 silver-plated conductive fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com