Preparation method of H-grade water-solubility silicon steel sheet paint

A silicon steel flake paint, water-soluble technology, applied in coatings, polyester coatings, etc., can solve the problems of agglomeration and agglomeration, paint liquid performance decline, paint liquid powder sedimentation and other problems, to improve the interface state, paint liquid volume and other problems Uniform and non-settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

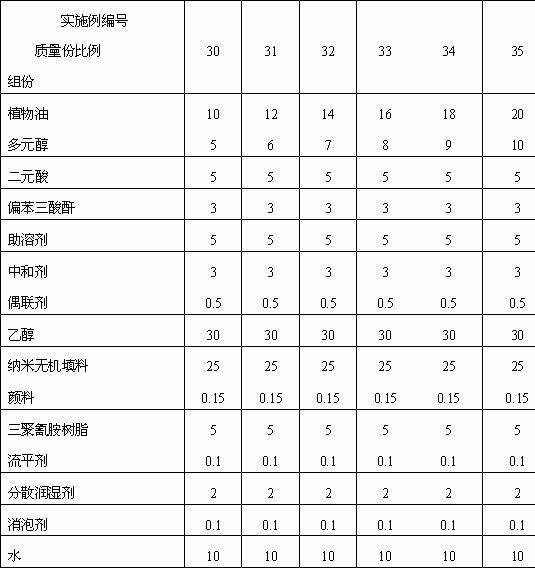

Examples

Embodiment 1

[0055] a. 440kg vegetable oil (catalysal oil: tung oil: linseed oil: castor oil mass ratio = 1:1:3:5, that is, the vegetable oil is composed of catalpa oil, tung oil, linseed oil, Composition with castor oil, the mass ratio described in the following examples (that is, the mass ratio of the raw material components described outside the brackets), 220kg glycerol is added to the reactor, and the temperature is stirred to 150°C ± 5°C for alcoholysis reaction 2h, then heat up to 200°C±5°C for alcoholysis for about 1h, cool down to below 200°C, add 110kg of isophthalic acid, react at 250°C for 2-4h, cool down to 180°C, add 66kg of trimellitic anhydride, react at 175°C for 30-60min, After cooling down, add 110kg of co-solvent (ethylene glycol butyl ether: propylene glycol ether: ethanol mass ratio = 2:1:4), add 66kg of neutralizing agent triethylamine below 60°C, and stir for 0.5h to obtain a water-soluble alkyd Resin, spare.

[0056] b. In the dispersion tank 1, add 11kg of coupli...

Embodiment 2

[0059] a. 440kg of vegetable oil (mass ratio of catalpa oil: tung oil: linseed oil: hydrogenated castor oil = 1:1:3:5), 110kg of polyols (mass ratio of neopentyl glycol and trimethylolpropane = 1:4) Add to the reaction kettle, stir and heat up to 150°C±5°C for alcoholysis for 2 hours, then heat up to 200°C±5°C for alcoholysis for about 1 hour, cool down to below 200°C, add 110kg of isophthalic acid, react at 250°C for 2-4 hours, cool down Add 66kg of trimellitic anhydride to 180°C, react at 175°C for 30-60min, add 110kg of co-solvent after cooling down (ethylene glycol butyl ether: butanol: ethylene glycol propyl ether: propylene glycol methyl ether mass ratio = 1:5:1:1 ), add 66kg of neutralizing agent triethylamine below 60°C, and stir for 0.5h to obtain a water-soluble alkyd resin for later use.

[0060] b. In the dispersion tank 1, add 11kg of coupling agent silane coupling agent and 660kg of ethanol and mix evenly, then add 550kg of nanometer inorganic filler silica and c...

Embodiment 3

[0063] a. Add 220kg of vegetable oil (mass ratio of catalpa oil: soybean oil: linseed oil: castor oil = 1:1:3:5) and 220kg of trimethylolpropane to the reactor, stir and heat up to 150℃±5℃ for alcoholysis reaction for 2 hours , then heat up to 200°C±5°C for alcoholysis for about 1h, cool down to below 200°C, add 110kg of isophthalic acid, react at 250°C for 2-4h, cool down to 180°C, add 66kg of trimellitic anhydride, react at 175°C for 30-60min, cool down Finally, add 110kg of co-solvent (ethylene glycol propyl ether: butanol mass ratio = 1:7), add 66kg of neutralizing agent ammonia water below 60°C, and stir for 0.5h to obtain a water-soluble alkyd resin for later use.

[0064] b. In the dispersion tank 1, add 11kg of coupling agent titanate coupling agent and 660kg of ethanol and mix evenly, then add 550kg of nanometer inorganic filler aluminum oxide and disperse with high-speed stirring to make it fully wet. Then, at normal temperature, after most of the ethanol is volatili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com