Preparation method for polymethacrylimide composite foam conductive wave-absorbing material

A technology of polymethacrylimide and polymethacrylimide resin, which is applied in the field of preparation of polymethacrylimide composite foam conductive wave-absorbing materials, can solve the problems of easy precipitation, poor wave-absorbing performance, No problems such as frequency absorption performance, good dispersion uniformity and compatibility, enhanced overall mechanical properties, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

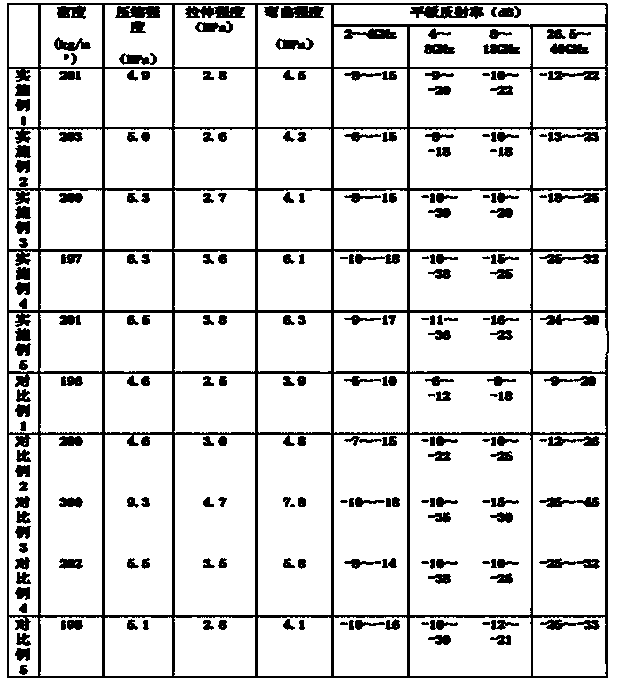

Embodiment 1

[0052] A preparation method of polymethacrylimide composite foam conductive wave-absorbing material, comprising the steps of:

[0053] Step 1: Preparation of expandable polymethacrylimide resin particles

[0054] Weigh 50 parts by weight of methacrylic acid, 50 parts by weight of methacrylonitrile, 10 parts by weight of the third monomer, 10 parts by weight of functionalized wave absorbing agent, 5 parts by weight of dispersant, 5 parts by weight of anti-settling agent, initiator 1 part by weight, 1.5 parts by weight of a nucleating agent, 1 part by weight of a polymerization inhibitor, 5 parts by weight of a cerium-containing foaming material and 1 part by weight of a crosslinking agent are added to the reactor, and these raw materials are first stirred mechanically, and then ultrasonically treatment to obtain a material mixture; then inject the obtained material mixture into a mold, first polymerize in a water bath at 45°C for 30 hours, then polymerize in a water bath at 60°...

Embodiment 2

[0071] A preparation method of polymethacrylimide composite foam conductive wave-absorbing material, comprising the steps of:

[0072] Step 1: Preparation of expandable polymethacrylimide resin particles

[0073] Weigh 40 parts by weight of acrylic acid, 60 parts by weight of acrylonitrile, 0.5 parts by weight of the third monomer, 1 part by weight of functionalized wave absorbing agent, 0.1 part by weight of dispersant, 1 part by weight of anti-settling agent, 0.05 parts by weight of initiator, 0.1 parts by weight of nucleating agent, 0.01 parts by weight of polymerization inhibitor, 0.5 parts by weight of cerium-containing foaming material and 0.2 parts by weight of crosslinking agent are added to the reactor, and these raw materials are mechanically stirred first, and then ultrasonically treated to obtain the material mixed solution; then inject the obtained material mixed solution into the mold, first polymerize in a water bath at 30°C for 10 hours, then polymerize in a wate...

Embodiment 3

[0090] A preparation method of polymethacrylimide composite foam conductive wave-absorbing material, comprising the steps of:

[0091] Step 1: Preparation of expandable polymethacrylimide resin particles

[0092] Weigh 60 parts by weight of methacrylic acid, 40 parts by weight of methacrylonitrile, 20 parts by weight of the third monomer, 30 parts by weight of functionalized wave absorbing agent, 10 parts by weight of dispersant, 10 parts by weight of anti-settling agent, initiator 2 parts by weight, 3 parts by weight of nucleating agent, 2 parts by weight of polymerization inhibitor, 10 parts by weight of cerium-containing foaming material and 2 parts by weight of crosslinking agent are added to the reactor, and these raw materials are first stirred by mechanical, and then ultrasonically treatment to obtain a material mixture; then inject the obtained material mixture into a mold, first polymerize in a water bath at 55°C for 60 hours, then polymerize in a water bath at 70°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com