Scratch-resistant outdoor powder paint

A powder coating, scratch-resistant technology, applied in powder coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve problems such as limited energy-saving effects, and achieve difficult precipitation, transparent and smooth coatings, and stable coating properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

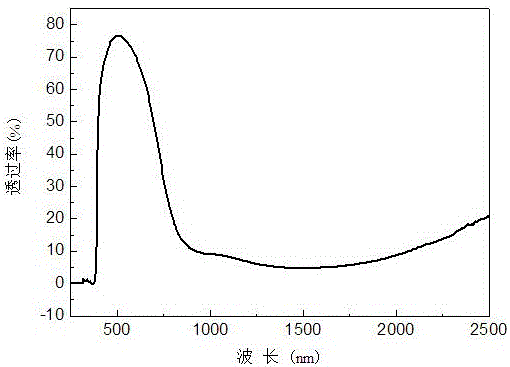

Image

Examples

Embodiment 1

[0029] A scratch-resistant outdoor powder coating, composed of the following raw materials in parts by weight: 5 parts of modified sericite, 10 parts of silicon dioxide, 8 parts of modified nano-tungsten tin oxide, 5 parts of barium sulfate, 7 parts of titanium dioxide, fat 1 part of amide ethanolamine, 1 part of silicone, 0.05 part of polydimethylsiloxane, 1 part of polytetrafluoroethylene wax, 30 parts of water-based polyurethane resin and 30 parts of silicone resin.

[0030] The preparation method of described modified sericite, its concrete steps are as follows:

[0031] (1) In terms of mass ratio, sericite: polyvinylpyrrolidone = 1:2, weigh sericite and polyvinylpyrrolidone (PVP) into a three-necked flask;

[0032] (2) Add ethanol and deionized water to the flask in step (1), disperse evenly by ultrasonic, add ammonia water while stirring, and continue stirring for 30 minutes;

[0033] (3) Add tetraethyl orthosilicate (TEOS) to the mixture in step (2), and stir at room t...

Embodiment 2

[0042] A scratch-resistant outdoor powder coating, composed of the following raw materials in parts by weight: 6 parts of modified sericite, 10 parts of silicon dioxide, 10 parts of modified nano-tungsten tin oxide, 5 parts of barium sulfate, 7 parts of titanium dioxide, fat 2 parts of diethylethanolamine, 2 parts of silicone, 0.07 parts of polydimethylsiloxane, 1 part of polytetrafluoroethylene wax, 30 parts of water-based polyurethane resin and 30 parts of silicone resin.

[0043] The preparation method of described modified sericite, its concrete steps are as follows:

[0044] (1) In terms of mass ratio, sericite: polyvinylpyrrolidone = 1:2, weigh sericite and polyvinylpyrrolidone (PVP) into a three-necked flask;

[0045] (2) Add ethanol and deionized water to the flask in step (1), disperse evenly by ultrasonic, add ammonia water while stirring, and continue stirring for 30 minutes;

[0046] (3) Add tetraethyl orthosilicate (TEOS) to the mixture in step (2), and stir at r...

Embodiment 3

[0055] A scratch-resistant outdoor powder coating, composed of the following raw materials in parts by weight: 8 parts of modified sericite, 10 parts of silicon dioxide, 15 parts of modified nano-tungsten tin oxide, 5 parts of barium sulfate, 7 parts of titanium dioxide, fat Diethanolamine 3 parts, silicone 3 parts, polydimethylsiloxane 1 part, polytetrafluoroethylene wax 1 part, water-based polyurethane resin 30 parts and silicone resin 30 parts.

[0056] The preparation method of described modified sericite, its concrete steps are as follows:

[0057] (1) In terms of mass ratio, sericite: polyvinylpyrrolidone = 1:2, weigh sericite and polyvinylpyrrolidone (PVP) into a three-necked flask;

[0058] (2) Add ethanol and deionized water to the flask in step (1), disperse evenly by ultrasonic, add ammonia water while stirring, and continue stirring for 30 minutes;

[0059] (3) Add tetraethyl orthosilicate (TEOS) to the mixture in step (2), and stir at room temperature for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com