Water-based transparent super-amphiphobic nano-paint and preparation method and application thereof

A nano-coating, super-amphiphobic technology, applied in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of complex water-based super-amphiphobic coating processes, high costs, and harsh experimental conditions. Low cost, low risk, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

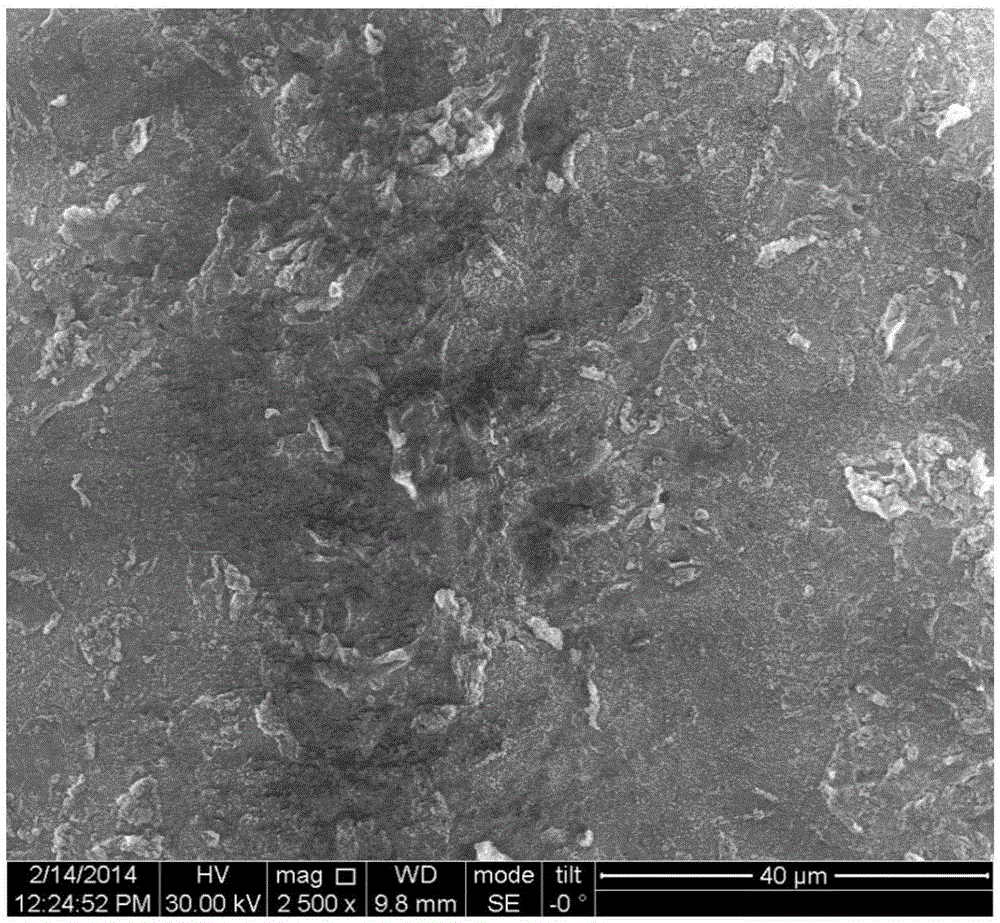

[0039] Preparation of water-based nano-coating: 40kHz frequency ultrasonic dispersion, and under the condition of 500-1000rpm mechanical stirring, slowly add deionized water into the high-solid-content nano-coating concentrate, the amount of water added is 1-90vol.% of the coating, and then immediately The surfactant is added in an amount of 0.01-1 vol.% of the water-based paint, and after 30-60 minutes, the water-based nano paint for preparing a transparent superamphiphobic surface can be obtained. The surfactant refers to sodium lauryl sulfate, Span80, Tween20, TritonX-100 or Surfynol61.

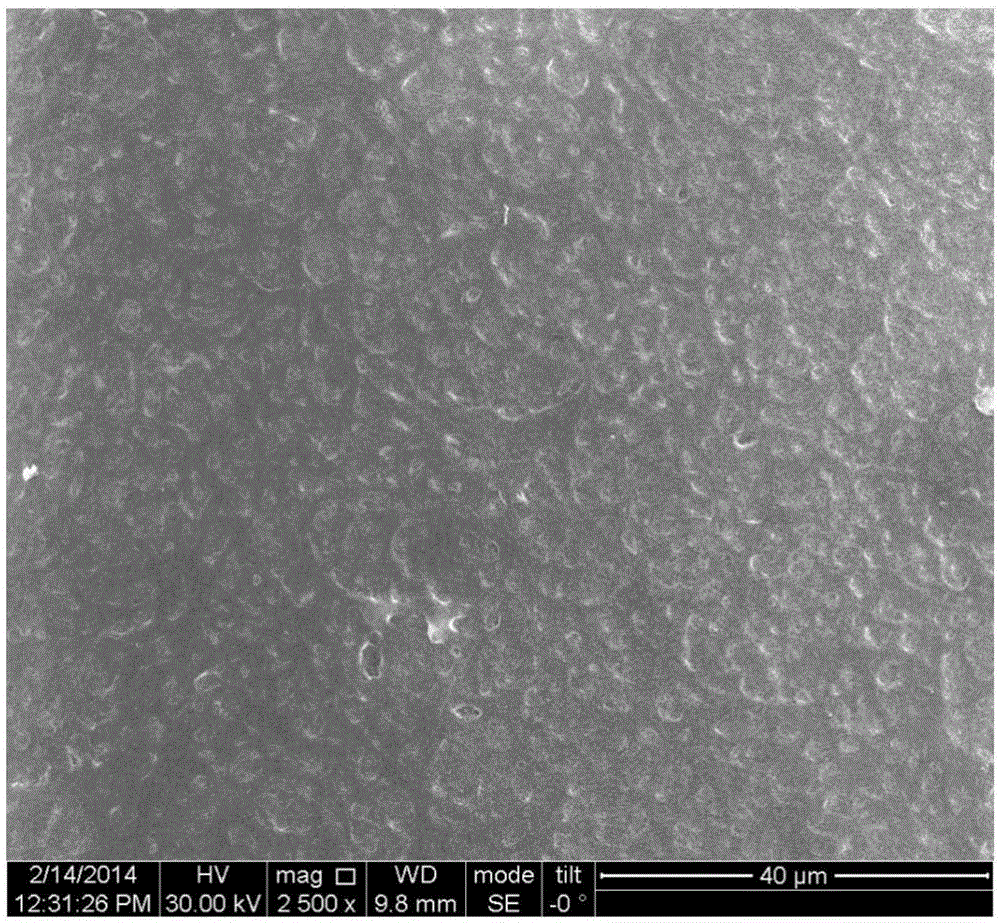

[0040] Spraying technology: before spraying, wipe the substrate with a clean cotton cloth, brush or dust-free paper, or ultrasonically clean it in ethanol for 5-15 minutes, take it out and dry it before using it. The substrate is glass, ceramic tile, concrete, metal, textile, plastic, wood, composite material, and the like. Choose a spray gun with a nozzle diameter of 0.5-2mm to spray, us...

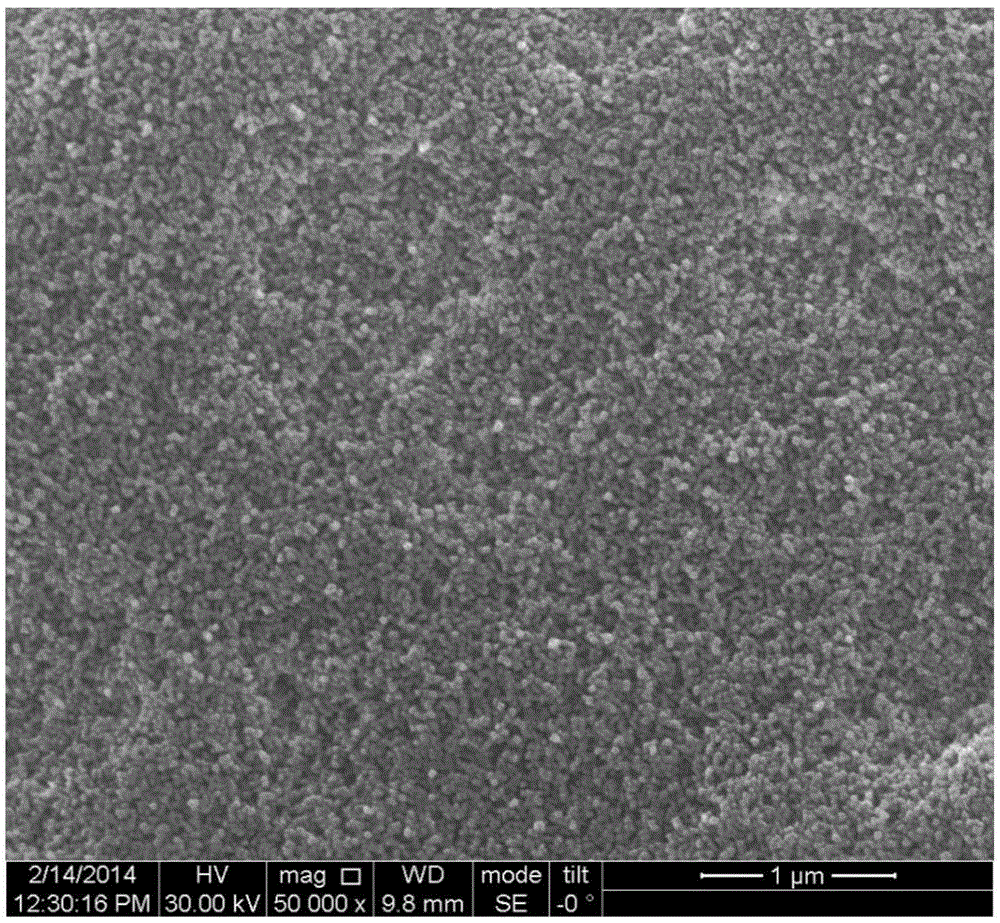

Embodiment 1

[0043] At room temperature of 25°C, the hydrophilic silica nanoparticles were added to ethanol (EtOH), and after ultrasonic dispersion at 40kHz frequency for 30min, under the condition of 800rpm magnetic stirring, ethyl orthosilicate was added at a volume ratio of 20:1 (TEOS), followed by dropwise addition of ammonia (NH 4 OH) the mixed solution of alkalized ethanol and deionized water, the dropping speed is 0.2mL / s, after reacting for 12h, drop in the silane coupling agent, the molar ratio is KH570:TEOS=2:1, the dropping speed is 0.5mL / s After continuing the magnetic stirring for 1 hour, slowly add fluorosilane (FAS) dropwise, the molar ratio FAS:TEOS=2:1, the dropping speed is 0.5mL / s, and after continuing the magnetic stirring for 24 hours, the oily nano-coating with a concentration of 1 mg / mL is obtained. According to the volume ratio of 1:1, add fluorocarbon resin solution to the oily nano coating to obtain the oily organic-inorganic hybrid coating, then put the oily nano...

Embodiment 2

[0046] Preparation of oil-based nano-coatings: Add hydrophilic silica nanoparticles to ethanol (EtOH) at room temperature at 20°C, disperse with 40kHz ultrasonic waves for 30 minutes, and add positive Ethyl silicate (TEOS), then, add dropwise the mixed solution of ethanol and deionized water acidified with hydrochloric acid (HCl), the drop rate is 0.3mL / s, after reacting for 24h, drop into the silane coupling agent, the molar ratio is KH570: TEOS = 3:1, drop rate 0.5mL / s, continue magnetic stirring for 1h, slowly add fluorosilane (FAS), molar ratio FAS: TEOS = 3:1, drop rate 0.3mL / s, continue magnetic stirring After 24 hours, a 6 mg / mL oily nano-coating was obtained.

[0047] Preparation of organic-inorganic hybrid coatings: First, add fluorocarbon resin solution to oily nano-coatings at a volume ratio of 1:1 to obtain oily organic-inorganic hybrid coatings, then put the oily nano-coatings into a rotary evaporator at 90°C Water bath, 200rmp condition, after evaporating for 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com