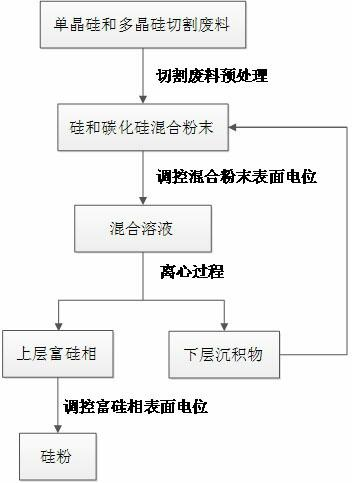

Method for recovering silicon powder from monocrystalline and polycrystalline silicon cutting wastes by utilizing potential adjustment centrifugal process

A technology for cutting waste and potential regulation, which is applied in the direction of chemical instruments and methods, silicon carbide, silicon compounds, etc., can solve the problems of difficult reduction principle, long process flow, complicated operation, etc., and achieves short separation operation time, simple process flow, The effect of process parameter stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

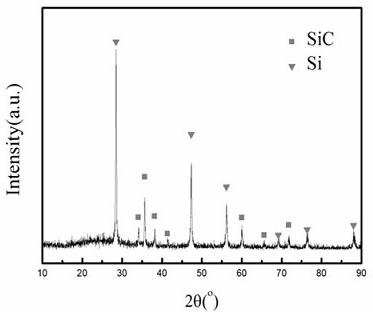

specific Embodiment 1

[0033] Add water to the mixed powder with polyethylene glycol removed according to the liquid-solid ratio of 4:1, adjust the pH value to 7 with sodium hydroxide solution, put the mixed solution into a centrifuge, centrifuge for 10 minutes, and rotate at 5000 rpm / min, the number of centrifugation is 3 times, the upper layer liquid is taken out and the pH value is adjusted to 2, the silicon powder settles rapidly, dried and recovered; the lower layer liquid is returned to the original mixed powder solution. It can be seen from the XRD pattern that only a small amount of silicon carbide is contained in the recovered silicon powder.

specific Embodiment 2

[0034] Add water to the mixed powder with polyethylene glycol removed according to the liquid-solid ratio of 10:1, adjust the pH value to 8 with sodium hydroxide solution, put the mixed solution into a centrifuge, centrifuge for 20 minutes, and rotate at 3000 rpm / min, the number of centrifugation is 5 times. Take out the upper layer liquid and adjust the pH value to 2, the silicon powder will settle rapidly, dry and recover; the lower layer liquid will return to the original mixed powder solution. Its XRD result is identical with embodiment one.

specific Embodiment 3

[0035] Add water to the mixed powder with polyethylene glycol removed according to the liquid-solid ratio of 5:1, adjust the pH value to 9 with sodium hydroxide solution, put the mixed solution into a centrifuge, centrifuge for 15 minutes, and rotate at 4000 rpm / min, the number of centrifuges is 4 times. Take out the upper layer liquid and adjust the pH value to 2, the silicon powder will settle rapidly, dry and recover; the lower layer liquid will return to the original mixed powder solution. Its XRD result is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com