Lithium ion battery aqueous anode slurry and preparation method thereof

A lithium-ion battery and positive electrode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor consistency of water-based positive electrode slurry, difficulty in uniform dispersion of solid substances, poor battery cycle performance, etc., to achieve capacity The effect of good cycle performance, good consistency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

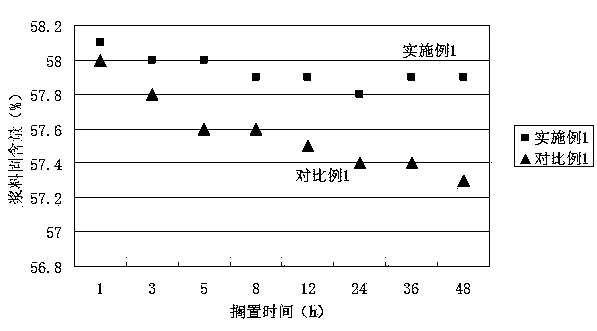

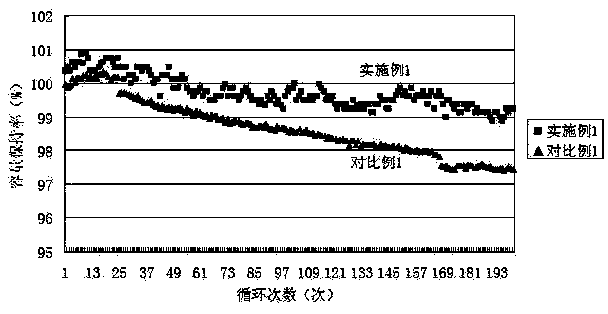

Embodiment 1

[0036] (1) Premix preparation: Weigh the positive electrode active material, carbon nanotubes, conductive agent, water-based binder and deionized water according to the ratio. The specific ratio of each component is shown in Table 1. The specific ratio of the water-based binder is The composition is shown in Table 2. Add deionized water and water-based binder accounting for 60% of the total mass of deionized water into a planetary slurry mixer and stir at a low speed for 30 minutes to obtain a premixed liquid. The speed of low-speed stirring is 25r / min for revolution and 500r / min for rotation. min.

[0037] (2) Preparation of conductive glue: add carbon nanotubes and conductive agent to the premixed solution, and stir at high speed for 60 minutes to obtain conductive glue. The speed of high-speed stirring is 50r / min for revolution and 2500r / min for rotation.

[0038] (3) Primary dispersion: Grind the conductive glue solution in a colloid mill to a fineness of 6 μm.

[0039] (...

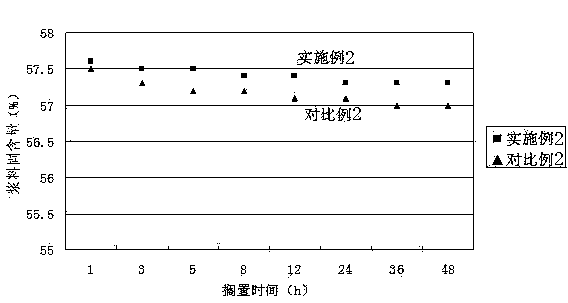

Embodiment 2

[0047] (1) Premix preparation: Weigh the positive electrode active material, carbon nanotubes, conductive agent, water-based binder and deionized water according to the ratio. The specific ratio of each component is shown in Table 1. The specific ratio of the water-based binder is The composition is shown in Table 2. Add deionized water and water-based binder accounting for 70% of the total mass of deionized water into a planetary slurry mixer and stir at a low speed for 20 minutes to obtain a premixed liquid. The speed of low-speed stirring is 50 r / min in revolution and 700 in rotation. r / min.

[0048] (2) Preparation of conductive glue: add carbon nanotubes and conductive agent to the premixed solution, and stir at high speed for 100 minutes to obtain conductive glue. The speed of high-speed stirring is 20r / min for revolution and 1800r / min for rotation.

[0049] (3) Primary dispersion: Grind the conductive adhesive solution in a sander to a fineness of 10 μm.

[0050] (4) S...

Embodiment 3

[0057] (1) Premix preparation: Weigh the positive electrode active material, carbon nanotubes, conductive agent, water-based binder and deionized water according to the ratio. The specific ratio of each component is shown in Table 1. The specific ratio of the water-based binder is The composition is shown in Table 2. Add deionized water and water-based binder accounting for 80% of the total mass of deionized water into a planetary slurry mixer and stir at a low speed for 10 minutes to obtain a premixed solution. The speed of low-speed stirring is 20 r / min for rotation and 1000 r for revolution. / min.

[0058] (2) Preparation of conductive glue: add carbon nanotubes and conductive agent to the premixed solution, and stir at high speed for 120 minutes to obtain conductive glue. The speed of high-speed stirring is 30r / min for revolution and 2000r / min for rotation.

[0059] (3) Primary dispersion: Grind the conductive glue solution in a colloid mill to a fineness of 5 μm.

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com