Built-in plug door device for rail vehicle

A rail vehicle and door leaf technology, which is applied in the field of built-in sliding door devices for rail vehicles, can solve problems such as uneven appearance, poor aerodynamic characteristics, and reduce the 2' width of the vehicle body, so as to improve safety and sealing. reliability, improve ride comfort, and solve the effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

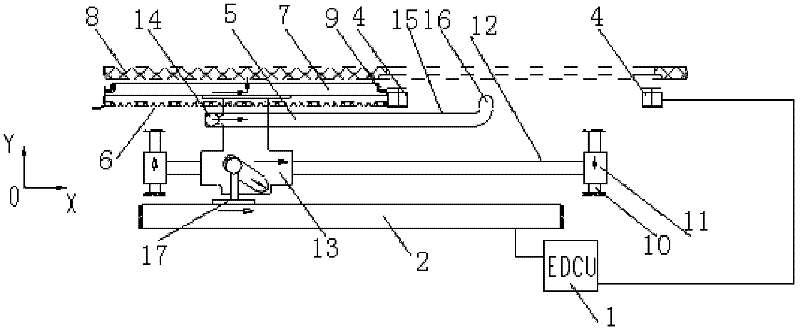

[0026] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

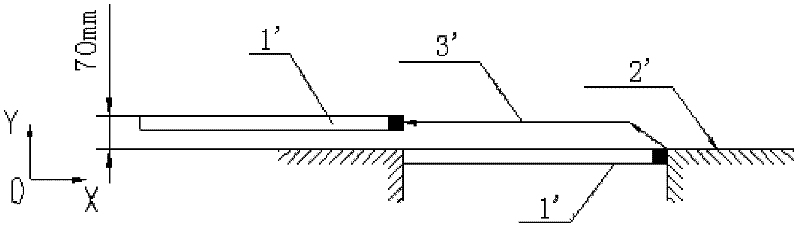

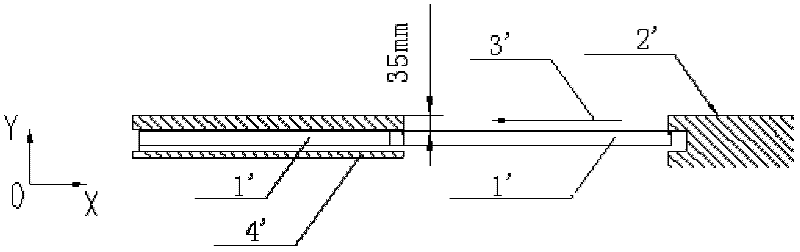

[0027] Such as image 3 As shown, this embodiment includes a control mechanism 1, a drive mechanism 2, a bearing mechanism 3, a pressing mechanism 4, a guide chute 5, a side wall partition 6, a door leaf 7, a car body 8 and a sealing mechanism 9; the side wall partition 6 is located at On the inner side of the car body 8, an interlayer is formed between the side wall partition wall 6 and the car body 8, and the size of the interlayer matches the door leaf 7; The inner side of the body 8; the carrying mechanism 3 includes a guide column 10, two sleeves 11, a connecting rod 12, a slider 13 and a guide wheel 14; wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com