Assembling device for display

A technology for display devices and assembling devices, which can be applied to identification devices, nonlinear optics, instruments, etc., can solve the problems of large-scale devices, decreased positioning accuracy, and reduced moving acceleration, and achieves high-precision assembly processing, improved positioning accuracy, and improved positioning accuracy. The effect of reducing inertial mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

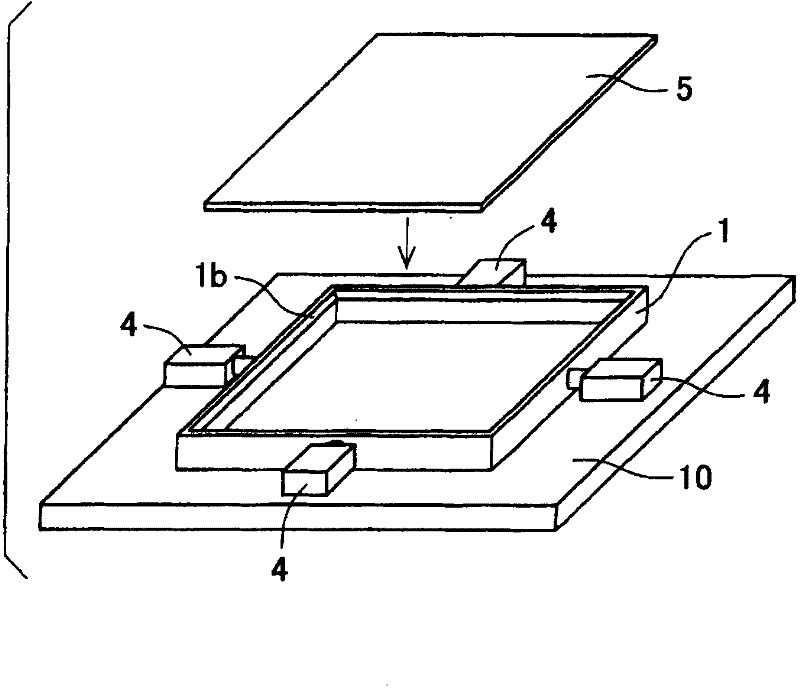

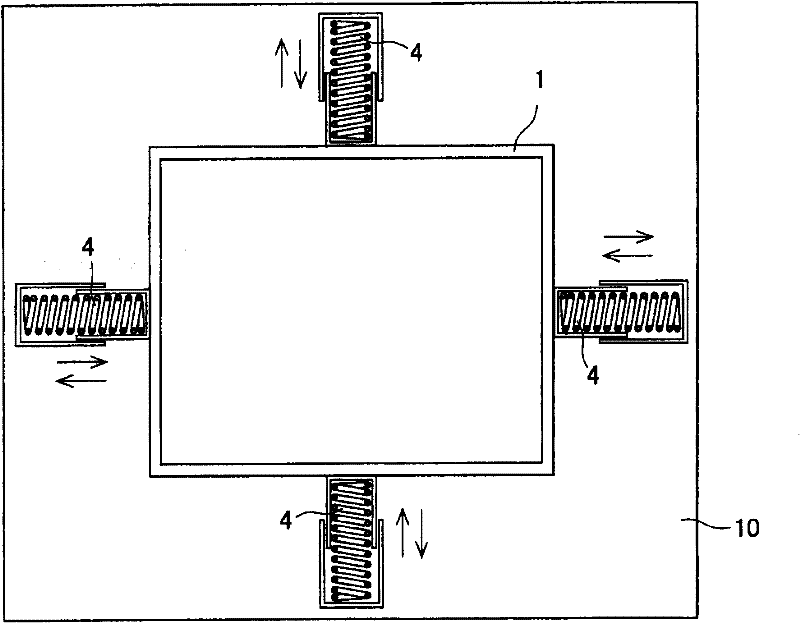

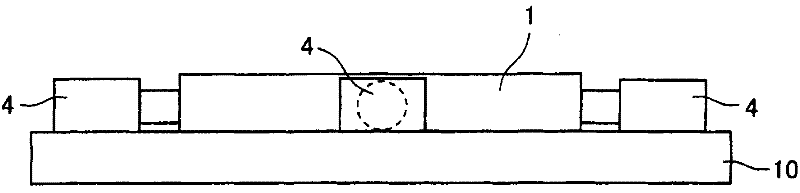

[0070] Embodiments of an apparatus for manufacturing a display device according to the present invention will be described below. figure 1 It is a perspective view illustrating an assembly device according to an embodiment of the present invention, showing a state in which a backlight unit (hereinafter referred to as a B / L unit) 1 and a panel 5 are assembled. In this embodiment, the panel 5 corresponding to the component for assembly is positioned by the suction hand of the transfer machine (not shown), sucked and held, and moved to the component corresponding to the component to be assembled placed on the loading table 10. Assembly is performed directly above the B / L unit 1. In this embodiment, if Figure 2A top view of and Figure 2B As shown in the side view of , the components are held while being centered by pressing the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com