Relay

A relay and armature technology, applied in relays, non-polar relays, electromagnetic relays, etc., can solve the problems of inability to build hybrid circuit breakers, increased disconnection time, and long contact disconnection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

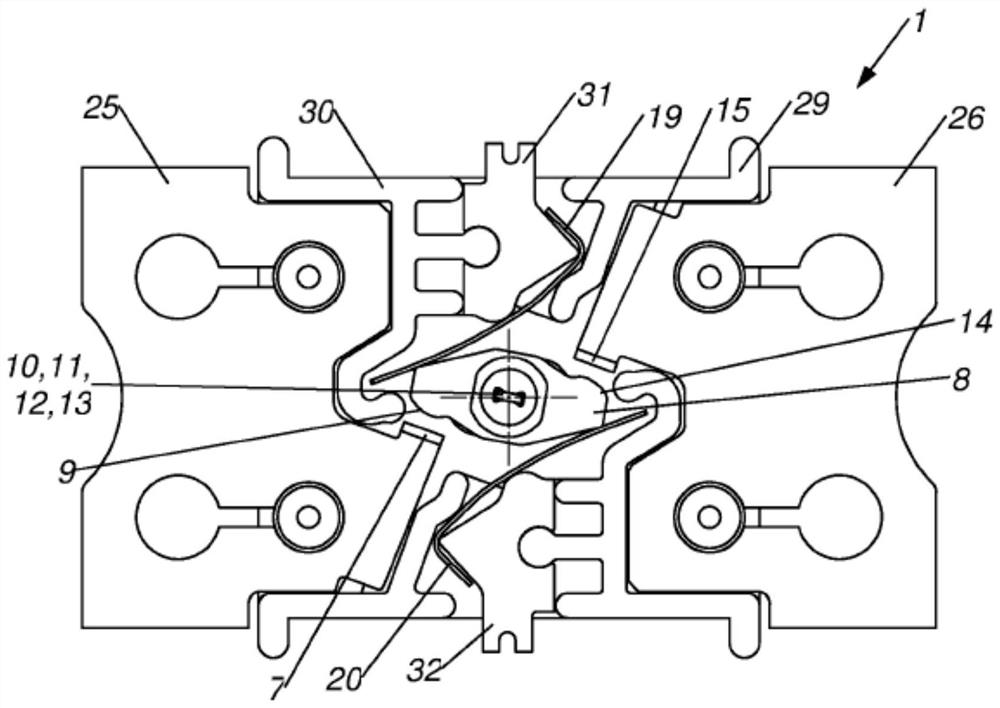

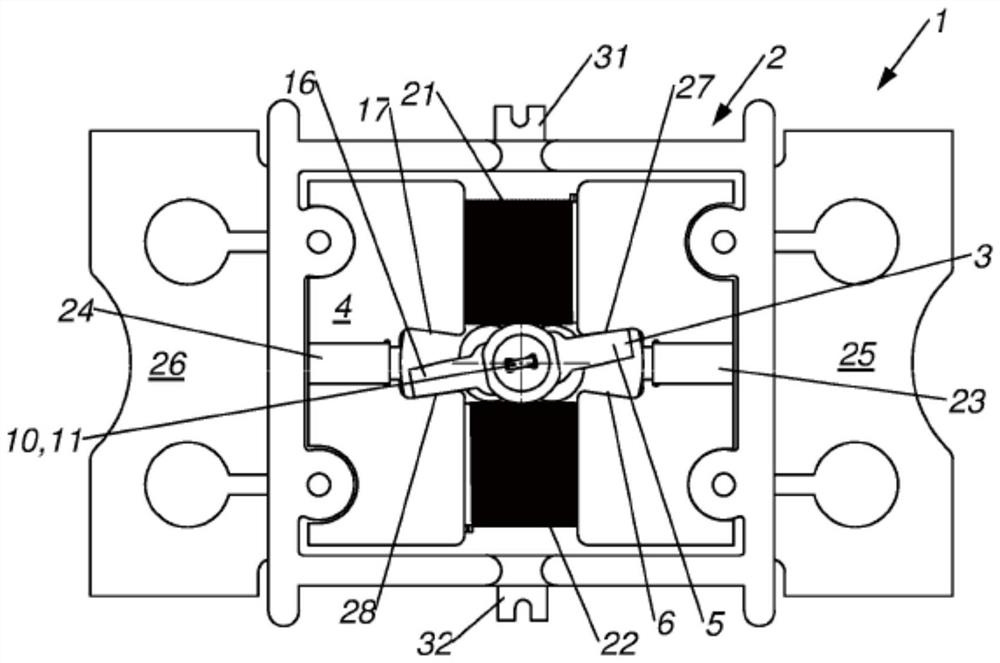

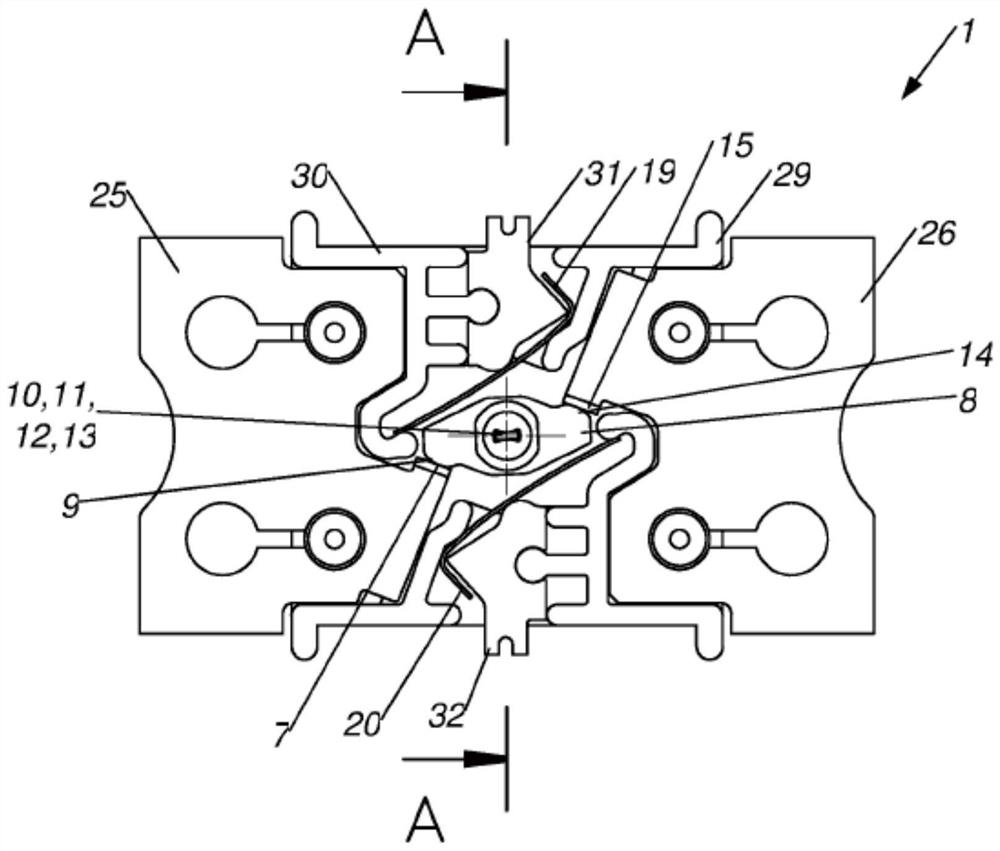

[0023] figure 1 5 shows a relay 1 comprising an electromagnetic drive unit 2 with a rotatable armature 3 comprising a first magnetic contact area 5 and a yoke 4 comprising a second magnetic contact area 6 and a first magnetic contact area 6. The contact area 5 is in contact with the second magnetic contact area 6 in the first state of the relay 1, the relay 1 further comprising at least a non-movable first electrical contact 7 and a movable contact arm 8 having at least a second electrical contact 9, In the first state, the first electrical contact 7 is in contact with the second electrical contact 9 , wherein the armature 3 and the contact arm 8 are arranged together on the shaft 10 and are embodied together with the shaft 10 as a torsion element 11 .

[0024] Therefore, the relay 1 according to the invention has a high contact pressure resulting in a low resistance. The relay 1 has no air gap between the yoke 4 and the armature 3, resulting in a low power demand on the coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com