An adjustable pretightening force double-layer shock-absorbing fastener system

A technology for damping fasteners and pre-tightening force, applied in the directions of roads, tracks, buildings, etc., can solve the problems of reducing pre-tightening force, increasing clearance, affecting the safety of trains, etc., achieving convenient operation, simple structure, and ensuring train safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described with reference to the accompanying drawings and specific embodiments.

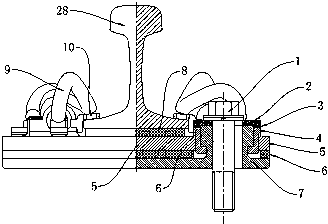

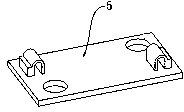

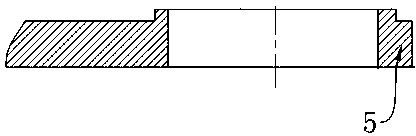

[0032] like figure 1 As shown, a double-layer shock-absorbing fastener system with adjustable pretightening force, the fastener system includes an anchor bolt assembly 1, a locking cover plate 2, a bottom plate connection sleeve 4, an upper bottom plate 5, and a bottom plate elastic insulation Pad 6, lower bottom plate 7, elastic insulating pad 8 under the rail, elastic bar 9 and gauge block 10; combine Figure 8 , the anchor bolt assembly includes an anchor bolt 25 , a flat washer 26 , and a spring washer 27 . combine Figure 4 , Figure 5 , the upper end surface of the lower bottom plate 7 has a boss 13, and there are two bosses 13; combined figure 2 , image 3, the upper bottom plate 5 has a through hole matched with the boss 13 of the lower bottom plate; the boss 13 on the lower bottom plate 7 passes through the through hole on the upper bottom plate 5; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com