A kind of steel belt pretensioning method

A steel belt and grooved technology, applied in the field of robots, can solve the problems of large volume, unsuitable multi-layer steel belt pretensioning, and uncompact structure of the robot steel belt pretensioning device, and achieves small size, compact structure, and occupied volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

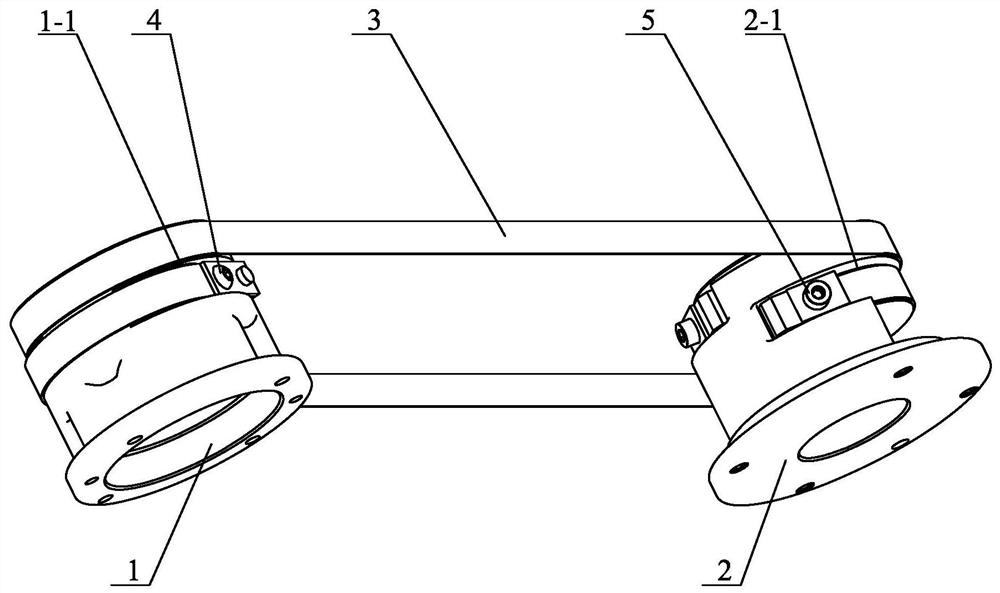

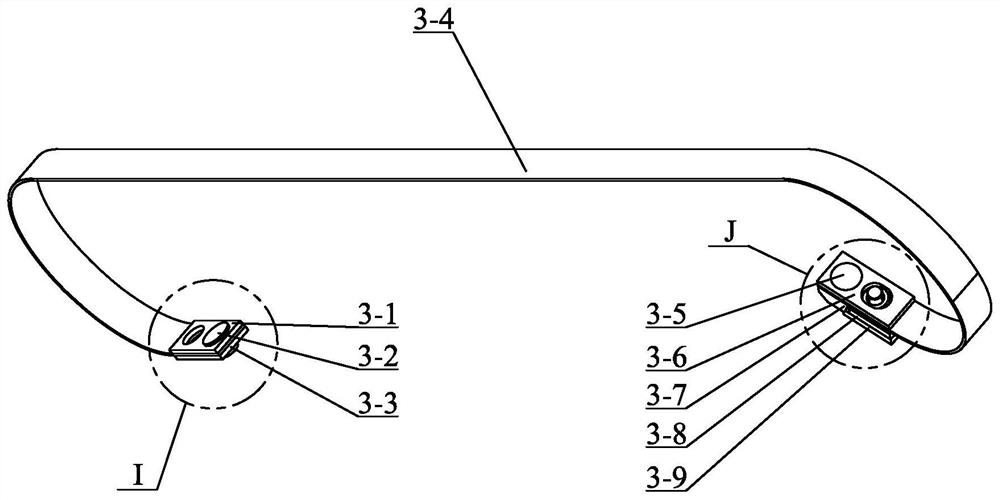

[0022] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, a steel belt pretensioning device described in this embodiment includes a steel belt pulley A1, a steel belt pulley B2, a steel belt assembly 3, a first fastening screw 4 and a second fastening screw 5, and the steel belt assembly One end of 3 is fixed on the outer peripheral side wall of the steel belt pulley A1 through the first fastening screw 4, and the other end of the steel belt assembly 3 is fixed on the outer peripheral side wall of the steel belt pulley B2 through the second fastening screw 5 superior;

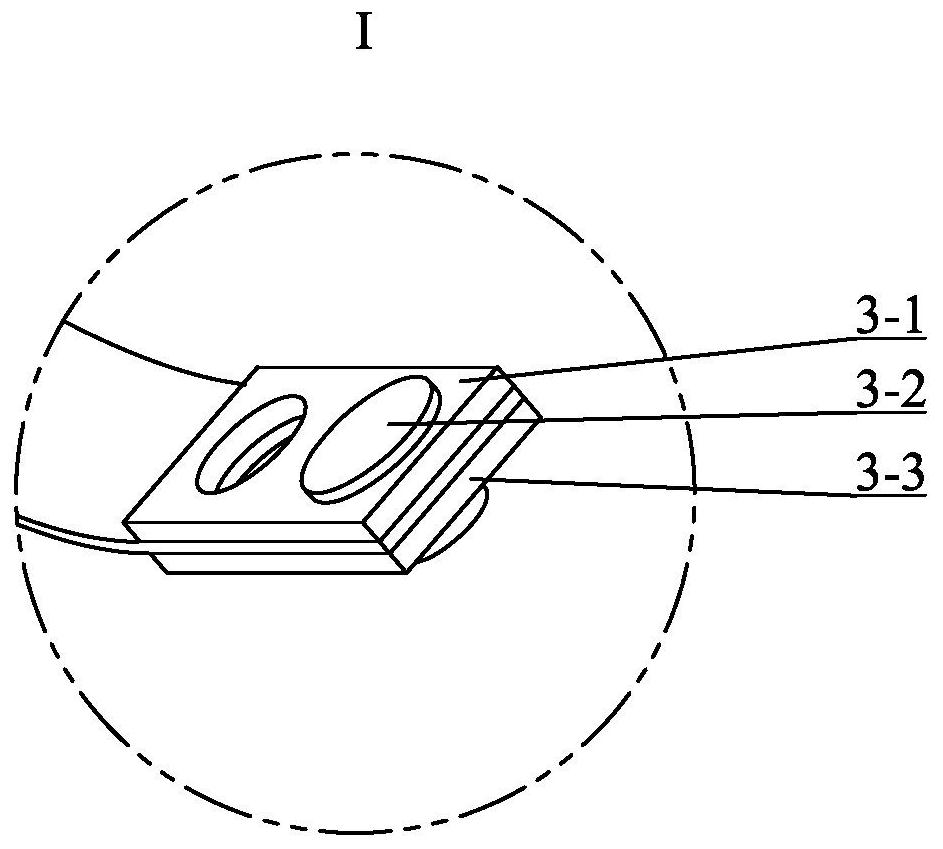

[0023] The steel belt assembly 3 includes a first pressing plate 3-1, a first cylindrical pin 3-2, a second pressing plate 3-3, a second cylindrical pin 3-5, a third pressing plate 3-6, a wedge-shaped pressing plate 3-7 and a fourth Pressing plate 3-9, one end of the steel strip 3-4 is fixedly connected between the first pressing plate 3-1 and the second pressing pla...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, the outer end surface of the fourth pressure plate 3-9 in this embodiment that cooperates with the groove wall of the wedge-shaped groove 3-7-1 is an inclined plane, and the inclined direction of the inclined surface is the same as the inclined direction of the groove wall of the wedge-shaped groove 3-7-1. unanimous. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0025] Such a design makes the inclined surface of the fourth pressing plate 3-9 cooperate with the groove wall of the wedge-shaped groove 3-7-1, so as to prevent stress concentration on the fourth pressing plate 3-9.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the outer peripheral side wall of the steel belt pulley A1 described in this embodiment is provided with a belt groove A1-1 along the circumferential direction, and one end of the steel belt assembly 3 is clamped in the belt groove A1-1, and the steel belt pulley The outer peripheral side wall of B2 is provided with a belt groove B2-1 along the circumferential direction, and the other end of the steel belt assembly 3 is clamped in the belt groove B2-1. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0027] It is designed in this way to facilitate the axial positioning between the steel belt assembly 3 and the steel pulley A1 and the steel pulley B2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com