Numerical control equipment spindle inner cone grinding device and grinding method of grinding device

A technology of grinding device and numerical control equipment, applied in the direction of grinding device, grinding drive device, grinding machine tool, etc., can solve the problems of damage to the transmission mechanism, fluctuation, uneven force of inner cone loss, etc., to prevent damage to the transmission mechanism, eliminate Impaired accuracy, the effect of eliminating force fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

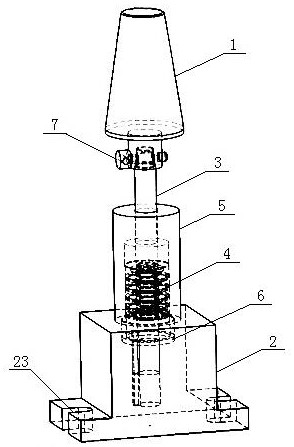

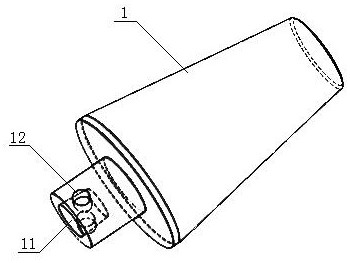

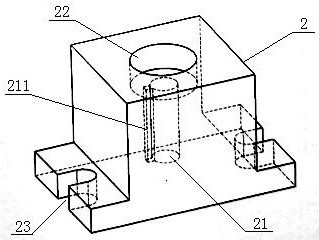

[0034] This embodiment discloses an inner cone grinding device for the main shaft of numerical control equipment. figure 1 , image 3 and Figure 4 , the grinding device includes a grinding knife handle 1 and a fixed base 2, the fixed base 2 is arranged on the workbench, the grinding knife handle 1 is installed on the fixed base 2 by supporting the connecting shaft 3; further, the bottom end of the supporting connecting shaft 3 An installation key 31 is provided, a fixing hole 21 is provided on the fixed base 2, a keyway 211 for limiting the installation key 31 is provided on the inner wall of the fixing hole 21, and the bottom end of the supporting connecting shaft 3 is inserted into the above-mentioned fixing hole 21 and The installation key 31 is located in the keyway 211; further, the fixed base 2 is also provided with a groove 22, the cross section of the groove 22 is circular, the groove 22 is coaxial with the fixing hole 21 and is connected with the fixing hole 21 thr...

Embodiment 2

[0043] This embodiment discloses an inner cone grinding device for the main shaft of numerical control equipment. figure 1 and Figure 5 , on the basis of Embodiment 1, the support connecting shaft 3 is sleeved with a pre-tension spring seat 5, and the pre-tension spring seat 5 is provided with a step hole 51 along the axial direction, which are respectively the first step hole 511 and the second step In the hole 512, the supporting connecting shaft 3 runs through two stepped holes, and the two ends are respectively connected with the grinding handle 1 and the fixed base 2, and the preload spring 4 and the supporting shoulder 32 are all arranged in the second stepped hole 512. The bottom end of the pre-tightening spring seat 5 is provided with an external thread, and the inner wall of the groove 22 is correspondingly provided with an internal thread, and the pre-tightening spring seat 5 is connected with the internal thread on the groove 22 by the external thread, thereby bein...

Embodiment 3

[0051] This embodiment discloses a method for grinding the inner cone of the main shaft of a numerical control equipment. The method is realized by the grinding device in the above embodiment. Apply it on the surface of the grinding tool holder, then move the machine tool so that the inner cone of the main shaft fits the grinding tool holder of the grinding device, manually rotate the main shaft, make the inner cone of the main shaft and the grinding tool holder automatically center and make them match evenly, and finally pass Fix the grinding device on the workbench by fixing the base, start the machine tool, and use the spindle to rotate to grind the inner cone of the spindle and the grinding handle.

[0052] In this implementation, the method of first aligning and then fixing the grinding device is used to realize the grinding of the inner cone of the main shaft. Compared with the prior art, the method of first fixing the grinding device and then using the numerical control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com