Shearing-type piezoelectric sensor module pre-loading device

A piezoelectric sensor, shear-type technology, applied in the field of sensors, can solve the problems of irrelevant research, low quality, low efficiency, etc., and achieve the effects of controllable process, stability between batches, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

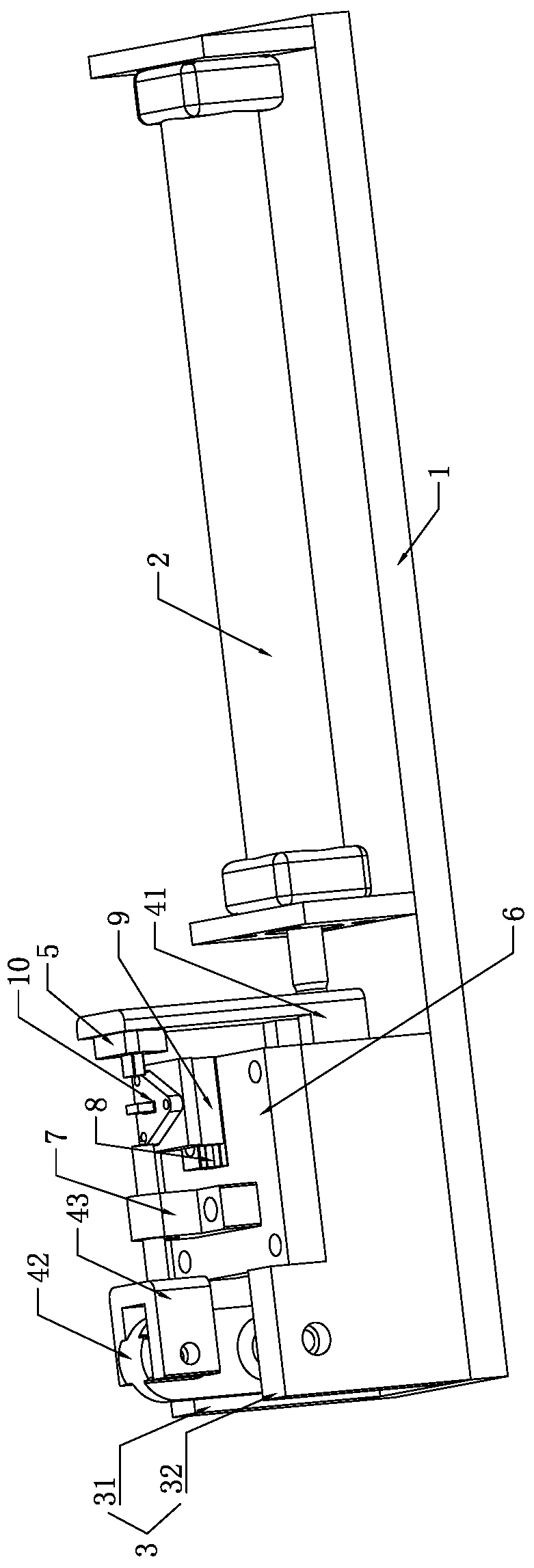

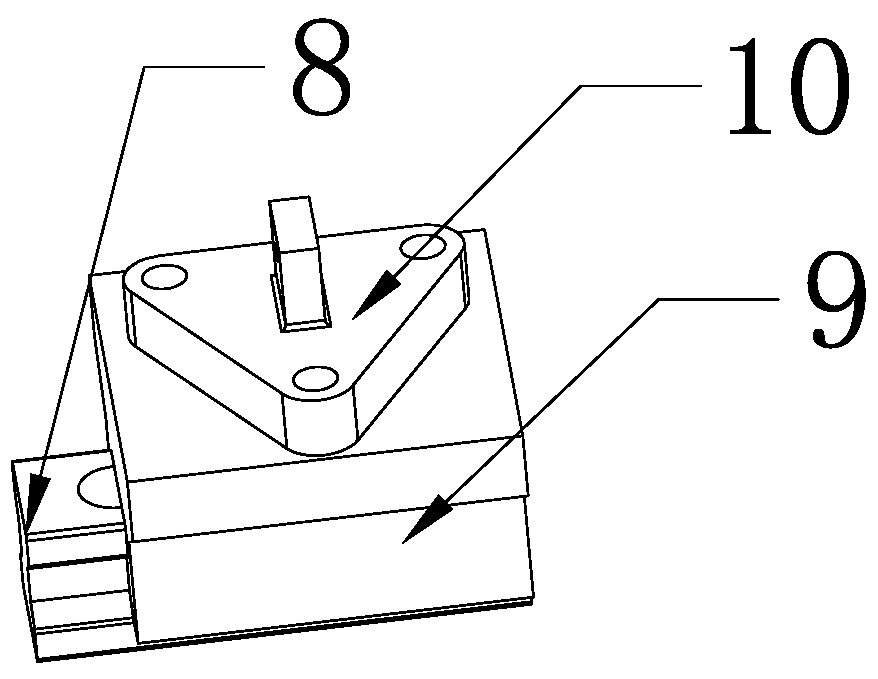

[0027] Such as Figure 1-3 As shown, a shear type piezoelectric sensor assembly pretensioning device disclosed by the present invention includes:

[0028] Base 1, the base 1 is designed as a long strip;

[0029] Power device 2, the power device 2 is arranged on the right end of the base 1, which can provide horizontal pulling force or thrust, the power device 2 can be a cylinder or a hydraulic cylinder, and the output pressure can be controlled by adjusting the air pressure or hydraulic pressure. According to actual needs, its There are also other power mechanisms that can provide thrust and pull;

[0030] Bracket 3, the bracket 3 is fixed on the left end of the base 1, the bracket 3 is composed of a front bracket 31 and a rear bracket 32, both the front bracket and the rear bracket are L-shaped, and the front bracket 31 and the rear bracket 32 are symmetrically arranged on the center line of the base 1 Base 1 front and rear;

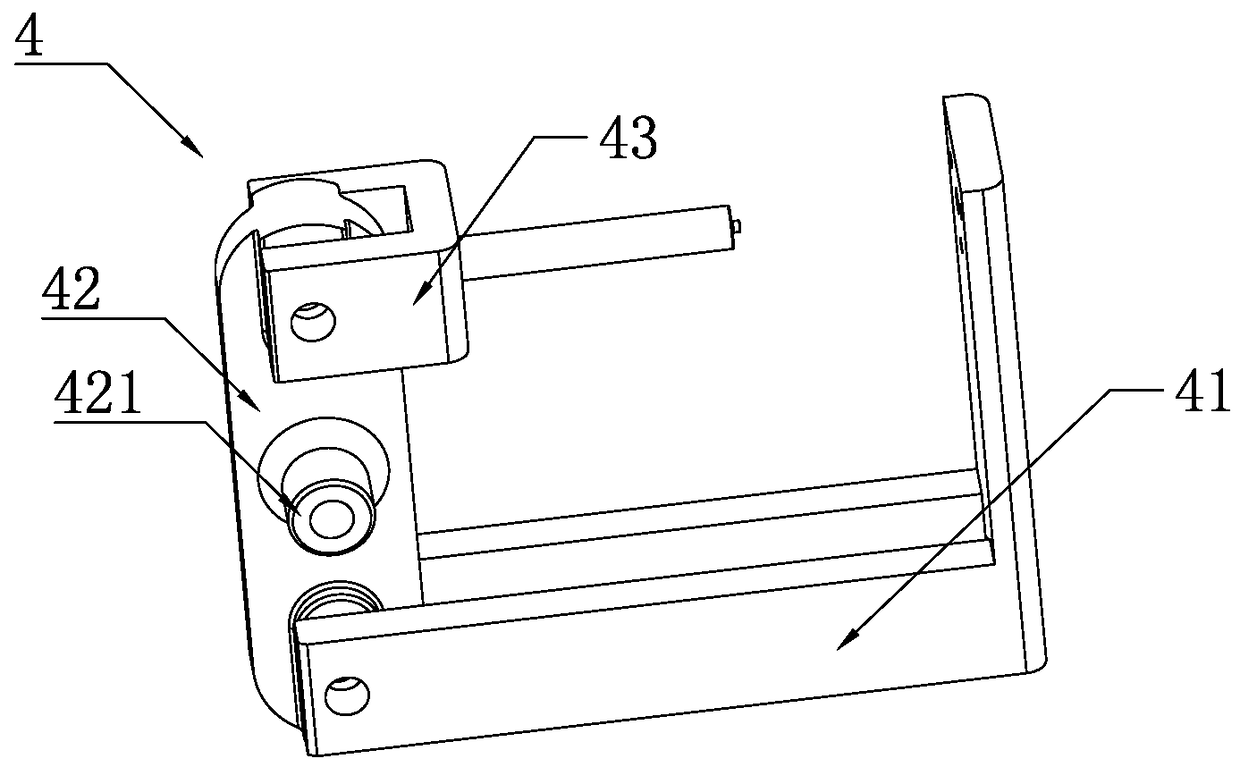

[0031] The drive link device 4 is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com