Anti-drift apparatus of device in microgravity environment and device

A microgravity, anti-drift technology, applied in the direction of quick-acting fasteners, bolts, etc., can solve the problems of mission failure, the anti-drift device has not been verified on-orbit, and the formation of space junk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

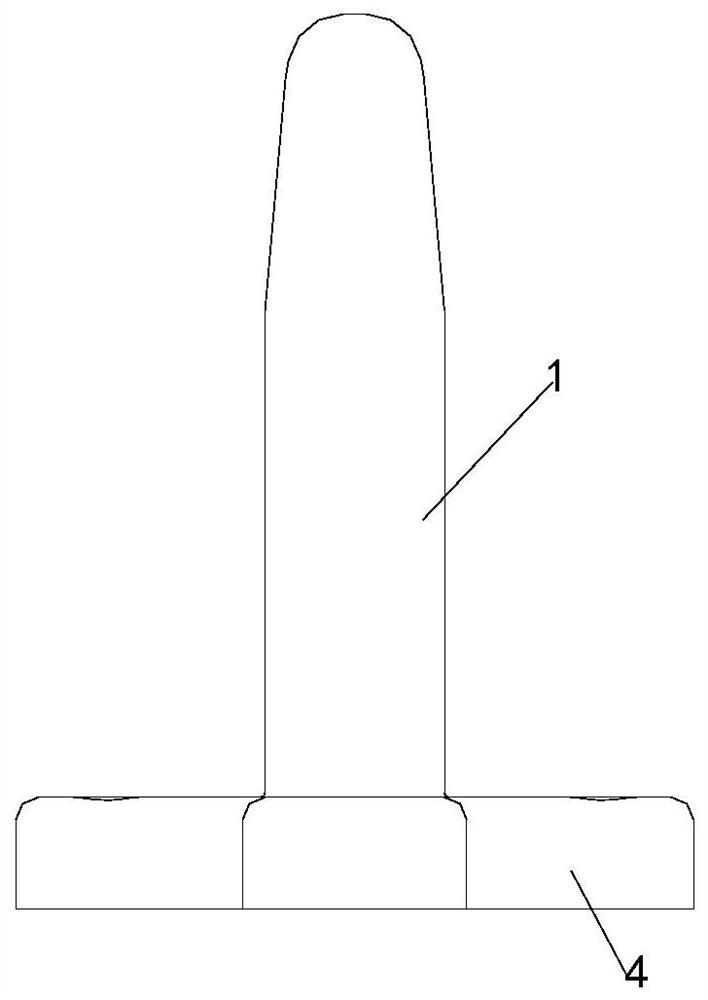

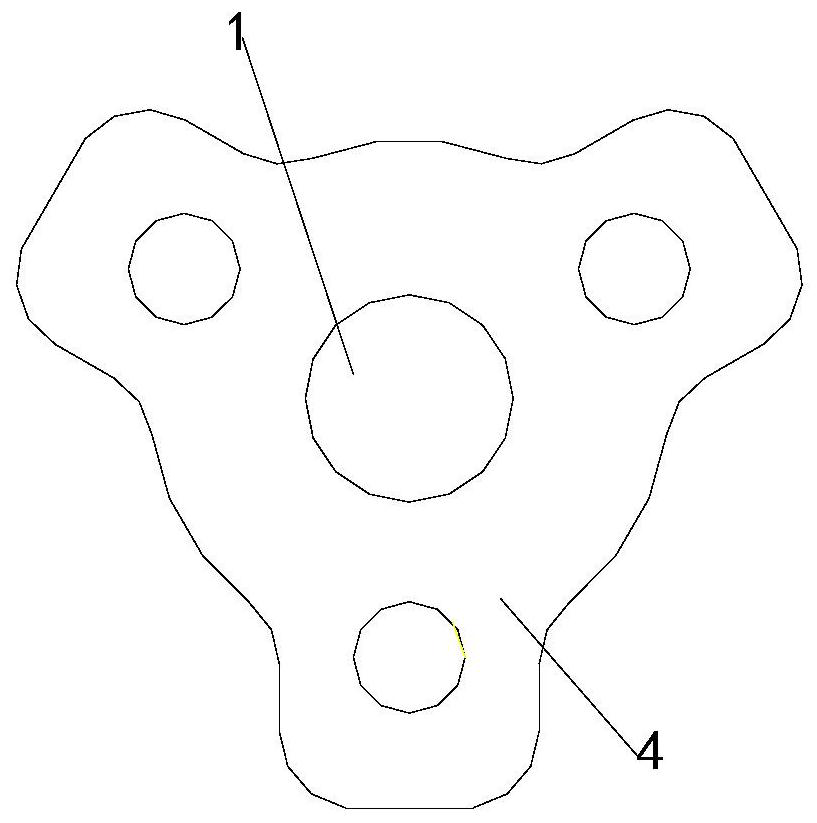

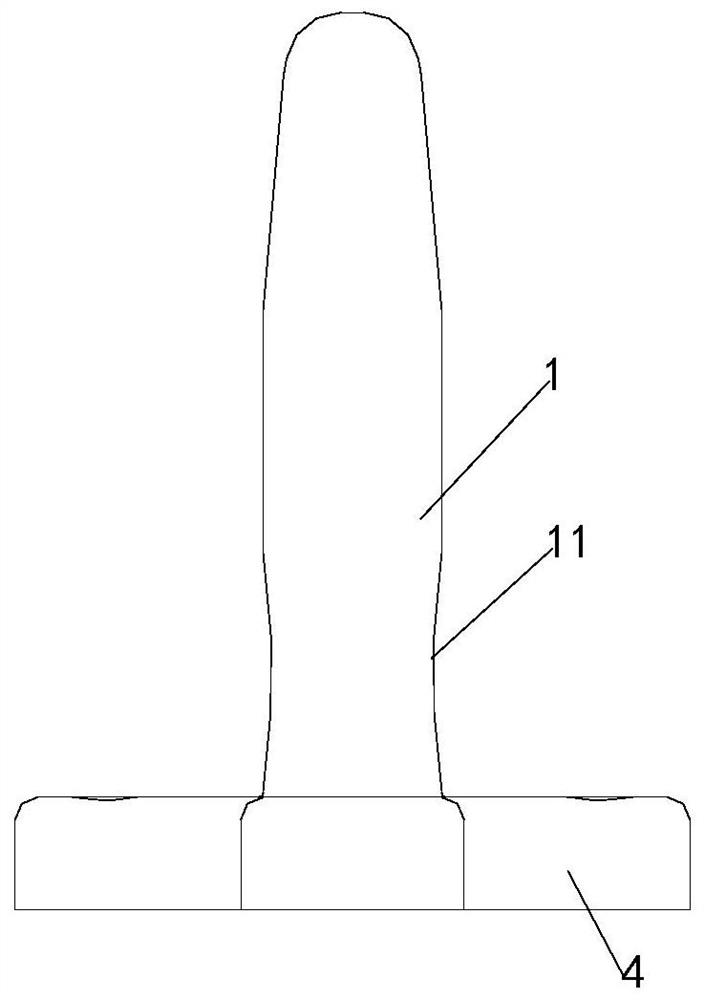

[0052] Such as Figure 1a-Figure 10 As shown, an anti-floating device for equipment in a microgravity environment includes an anti-floating component and a guiding and positioning component. The anti-floating component includes a locking pin 1 and an anti-floating guide sleeve 2. There is a locking through hole 21, and the locking pin 1 can be axially moved and inserted in the locking through hole 21; the guide positioning assembly includes a guide sleeve 6 and a guide pin 5, and the guide sleeve 6 is provided with a guide through hole, and the guide pin 5 can be axially moved and inserted in the guide through hole; the height of the guide pin 5 is greater than the height of the locking pin 1 .

[0053] Wherein, the locking pin 1 and the guide pin 5 of this embodiment may be of a cylindrical structure or a polygonal prism structure, etc., and the locking through hole 21 and the guiding through hole may be of suitable round holes or polygonal holes.

[0054] In this embodiment, ...

Embodiment 2

[0057] Such as Figure 1a-Figure 10 As shown, an anti-floating device for equipment in a microgravity environment includes an anti-floating component and a guiding and positioning component. The anti-floating component includes a locking pin 1 and an anti-floating guide sleeve 2. There is a locking through hole 21, and the locking pin 1 can be axially moved and inserted in the locking through hole 21; the guide positioning assembly includes a guide sleeve 6 and a guide pin 5, and the guide sleeve 6 is provided with a guide through hole, and the guide pin 5 can be axially moved and inserted in the guide through hole; the height of the guide pin 5 is greater than the height of the locking pin 1 .

[0058] Wherein, the locking pin 1 and the guide pin 5 of this embodiment may be of a cylindrical structure or a polygonal prism structure, etc., and the locking through hole 21 and the guiding through hole may be of suitable round holes or polygonal holes.

[0059] Such as Figure 6...

Embodiment 3

[0069] Such as Figure 1a-Figure 10 As shown, an anti-floating device for equipment in a microgravity environment includes an anti-floating component and a guiding and positioning component. The anti-floating component includes a locking pin 1 and an anti-floating guide sleeve 2. There is a locking through hole 21, and the locking pin 1 can be axially moved and inserted in the locking through hole 21; the guide positioning assembly includes a guide sleeve 6 and a guide pin 5, and the guide sleeve 6 is provided with a guide through hole, and the guide pin 5 can be axially moved and inserted in the guide through hole; the height of the guide pin 5 is greater than the height of the locking pin 1 .

[0070] Wherein, the locking pin 1 and the guide pin 5 of this embodiment may be of a cylindrical structure or a polygonal prism structure, etc., and the locking through hole 21 and the guiding through hole may be of suitable round holes or polygonal holes.

[0071] Such as Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com