Rotary induction and crankshaft assembly

A technology for introducing devices and rotating components, applied in the direction of shafts and bearings, bearing elements, ball bearings, etc., can solve problems such as large structural lengths, and achieve reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

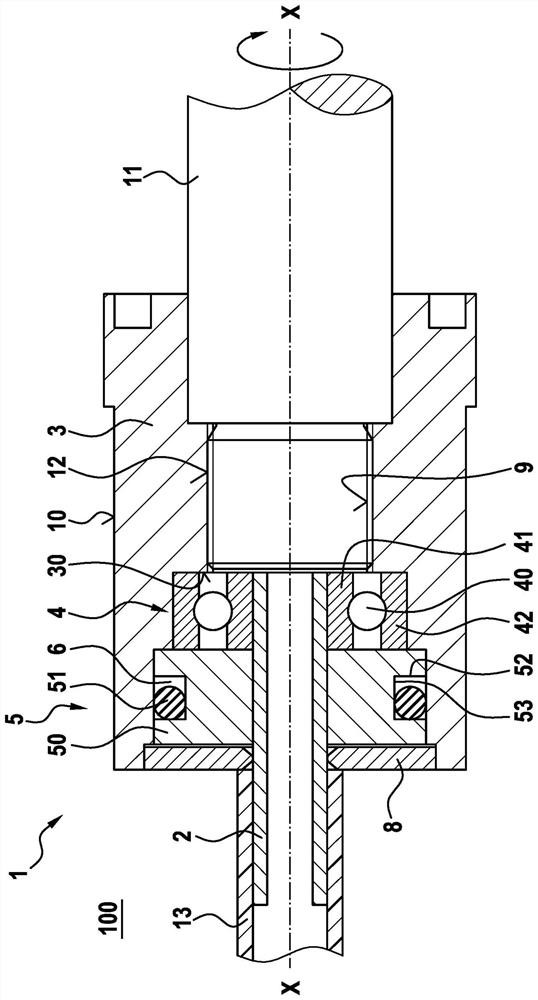

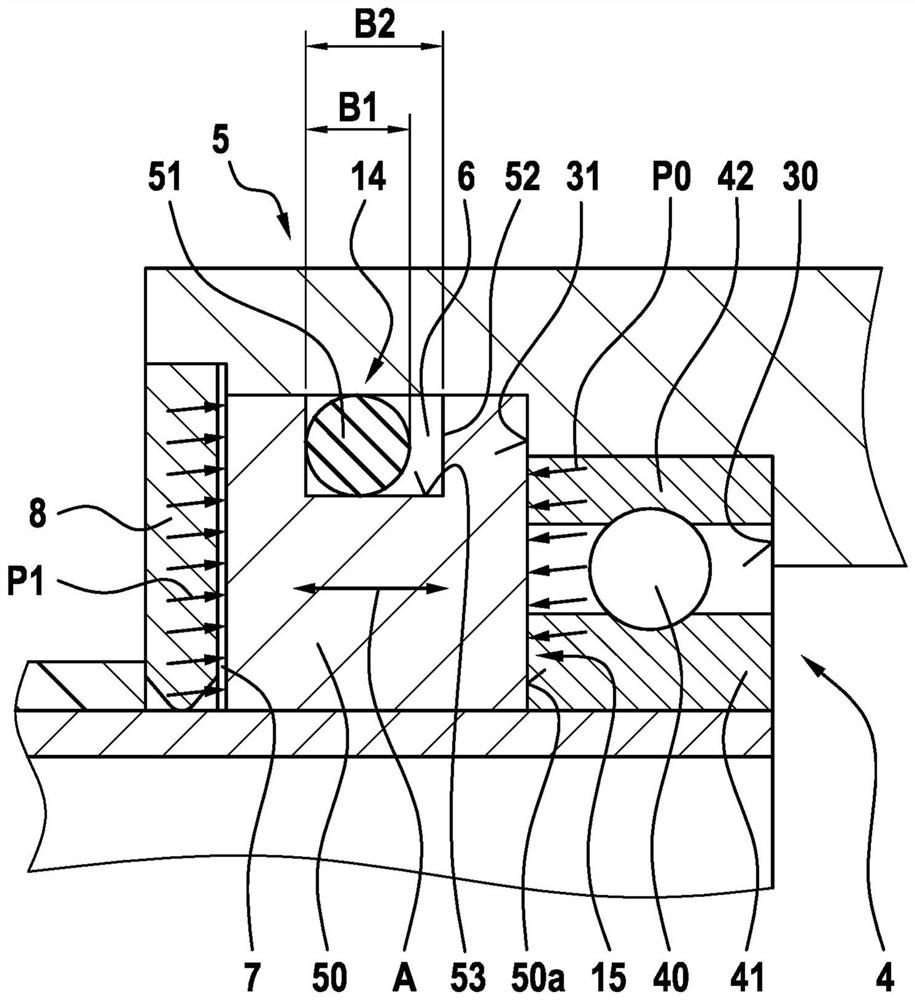

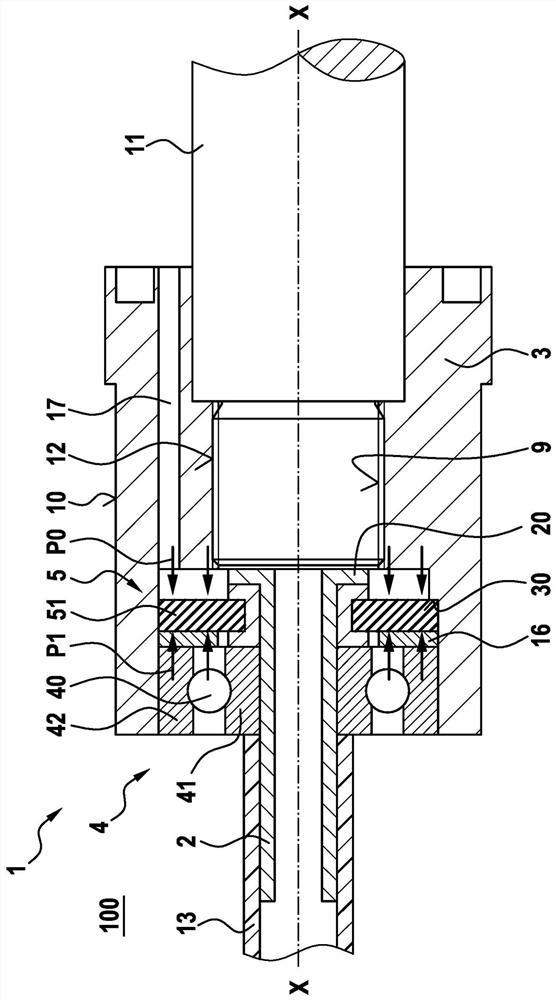

[0026] Refer below figure 1 and 2 The rotary introduction device 1 according to the first preferred embodiment of the present invention is explained in detail.

[0027] as from figure 1 It can be seen that the rotational introduction device 1 comprises a stationary member 2 and a rotating member 3 . The stationary component 2 is in this embodiment a pipe piece on which a hose 13 is arranged.

[0028] Thus, the rotating member 3 is arranged around the outer circumference of the stationary member 2 and has a notch provided in the axial direction X-X of the rotation introduction device, the notch having an internal thread 9 .

[0029] Furthermore, the rotational introduction device 1 also comprises exactly one bearing 4 , which is arranged between the stationary member 2 and the rotating member 3 .

[0030] The bearing 4 includes a plurality of rolling elements 40 , an inner bearing ring 41 and an outer bearing ring 42 . The bearing inner ring 41 is connected with the statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com