Semiconductor technology processing system and processing method thereof

A technology for semiconductors and process parts, which is applied in the field of semiconductor process processing systems and its processing, and can solve the problems of low reliability and complex mechanical structures of mass production devices for process parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

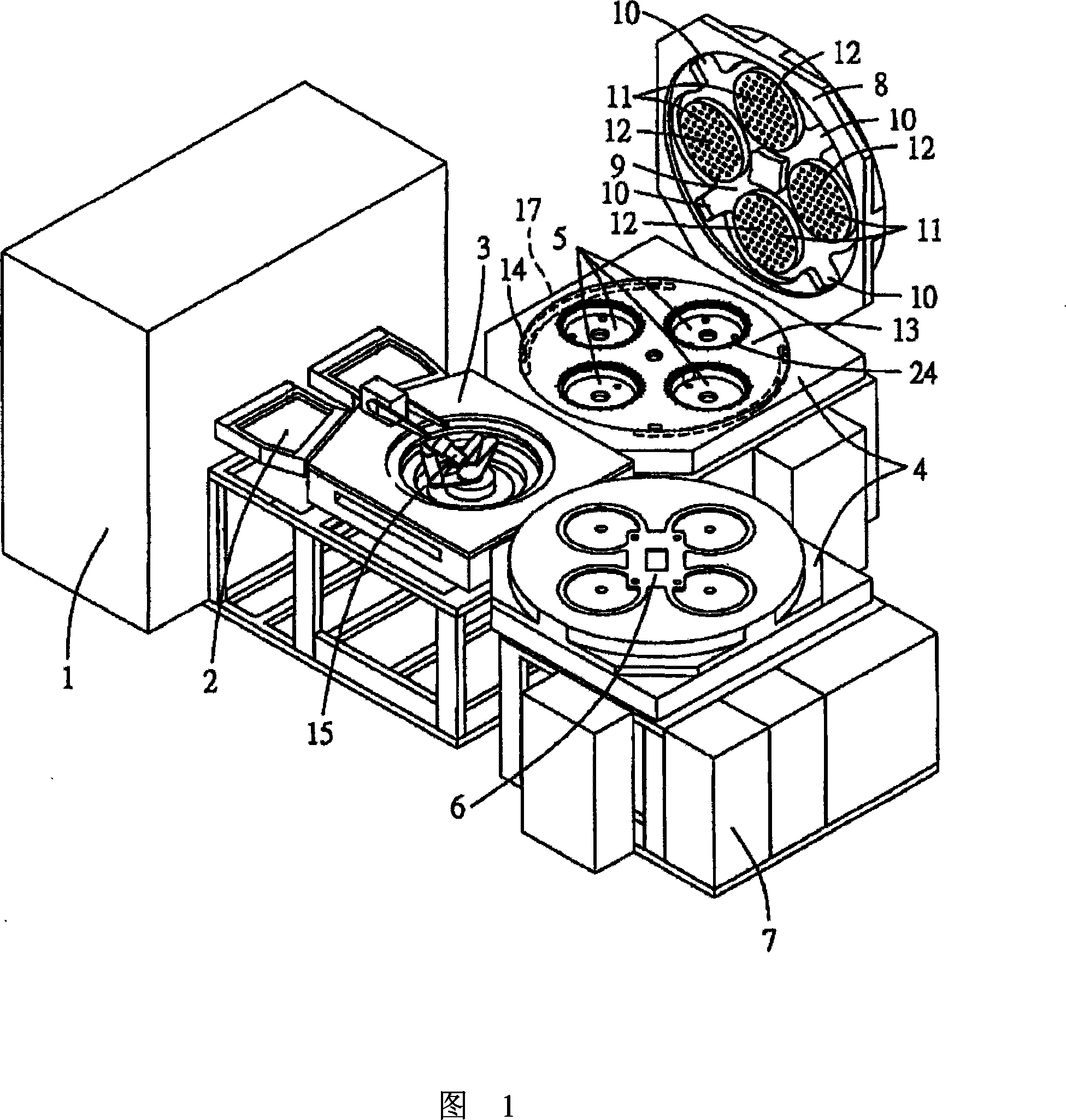

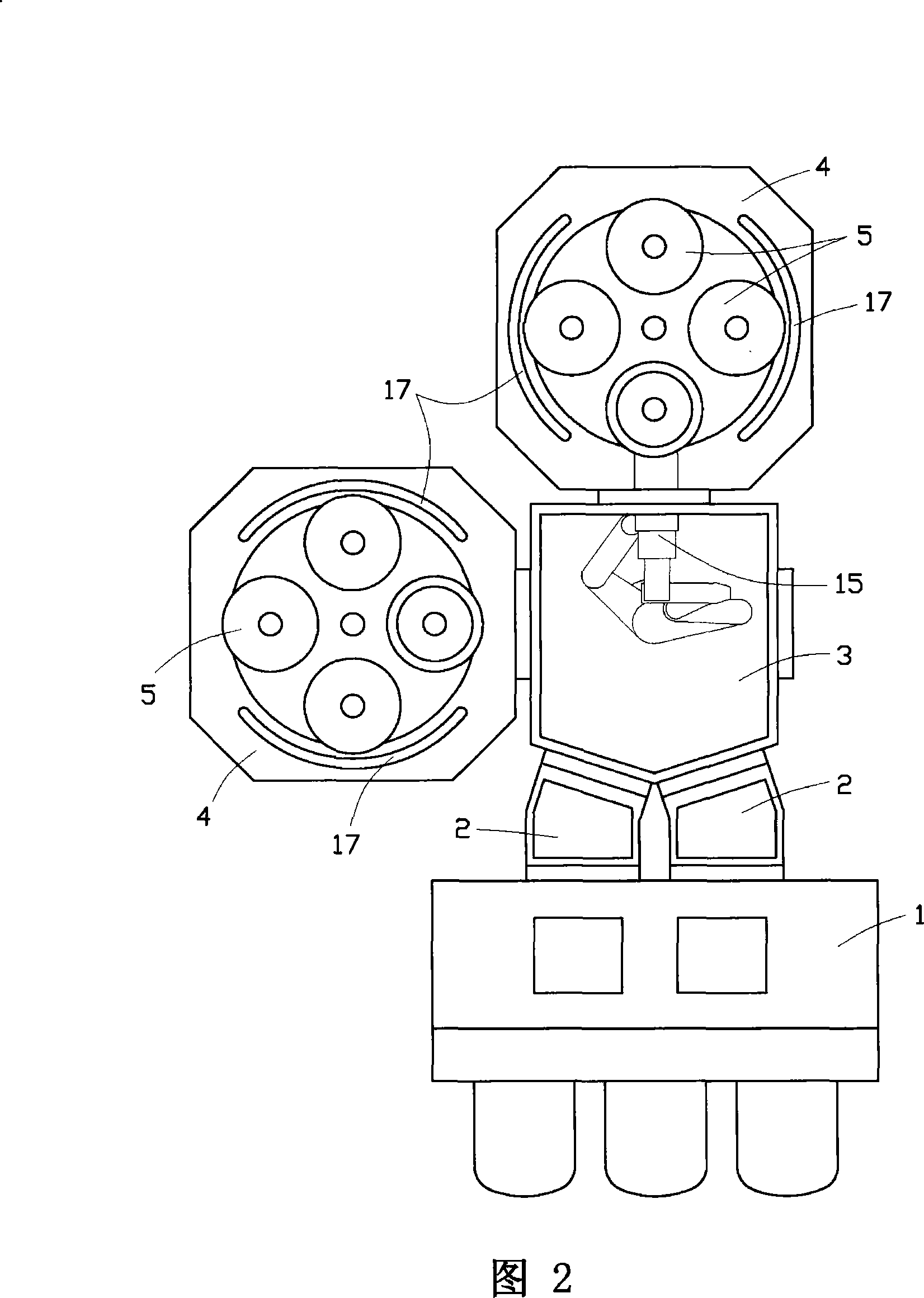

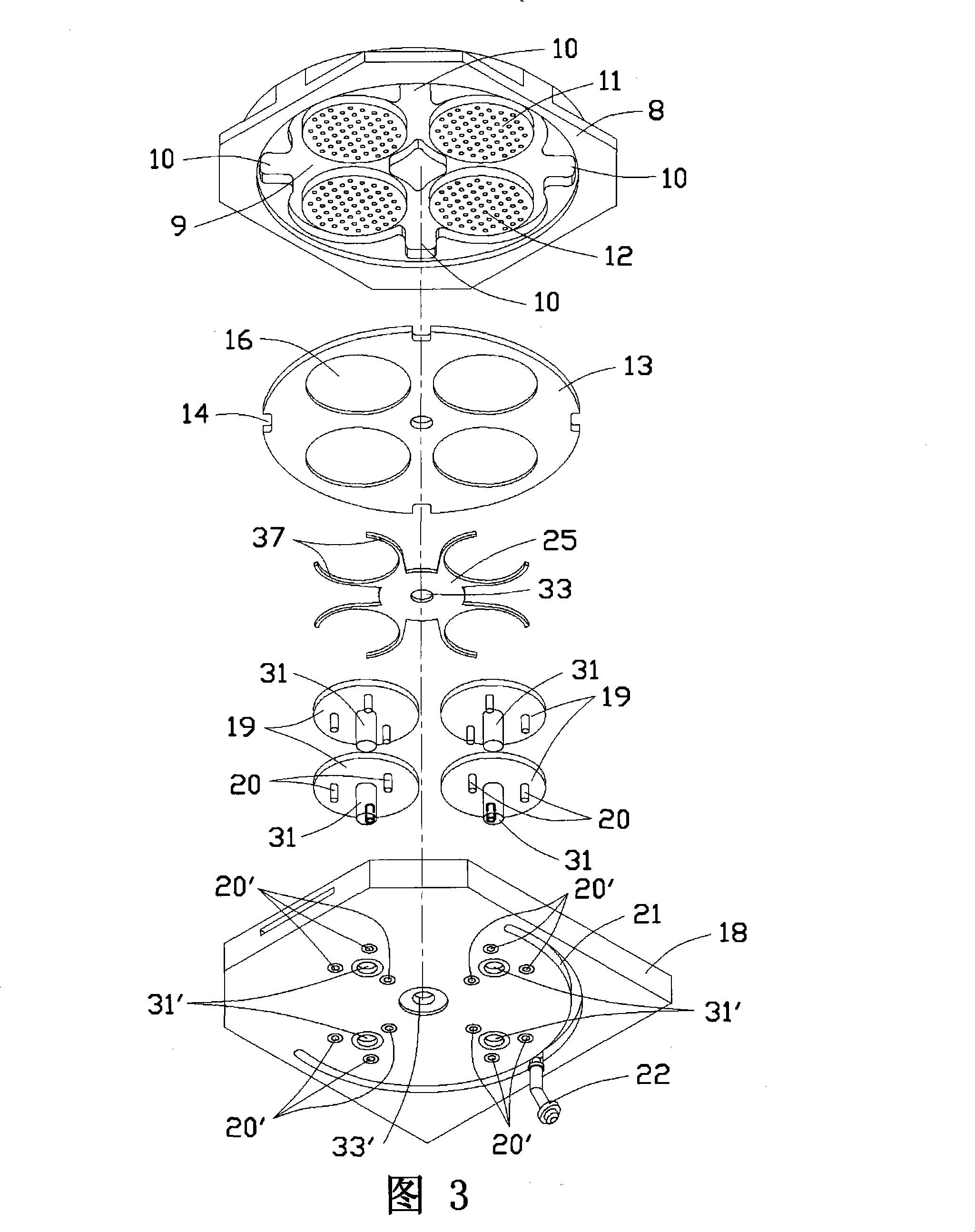

[0100]Please refer to FIG. 1 . FIG. 1 is a schematic perspective view of the semiconductor process system of the present invention. The present invention consists of a standard factory interface 1 , two vacuum locks 2 , a transfer chamber 3 , and one or more processing chambers 4 . Among them, the factory interface 1 is adjacent to the vacuum lock 2 . The transfer chamber 3 is located between the vacuum lock 2 and the processing chamber 4 . A plurality of processing chambers 4 may be arranged around the transfer chamber 3 . Each processing chamber 4 contains a plurality of processing platforms 5 , and each processing platform 5 can process a piece of semiconductor process. In the embodiment shown in FIG. 1 , the semiconductor processing system includes two processing chambers 4 arranged around the transfer chamber 3 . A chamber top cover 8 is arranged above each processing chamber 4. For the convenience of description of the present invention, the chamber top cover 8 of one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com