CO (carbon monoxide) full-radial isothermal converting furnace

A technology of isothermal transformation and furnace body, which is applied in the field of temperature transformation furnace, can solve the problems of reactor overtemperature, isothermal reactor overtemperature, complex structure, etc., and achieve the effect of uniform gas distribution, small bed resistance and large flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

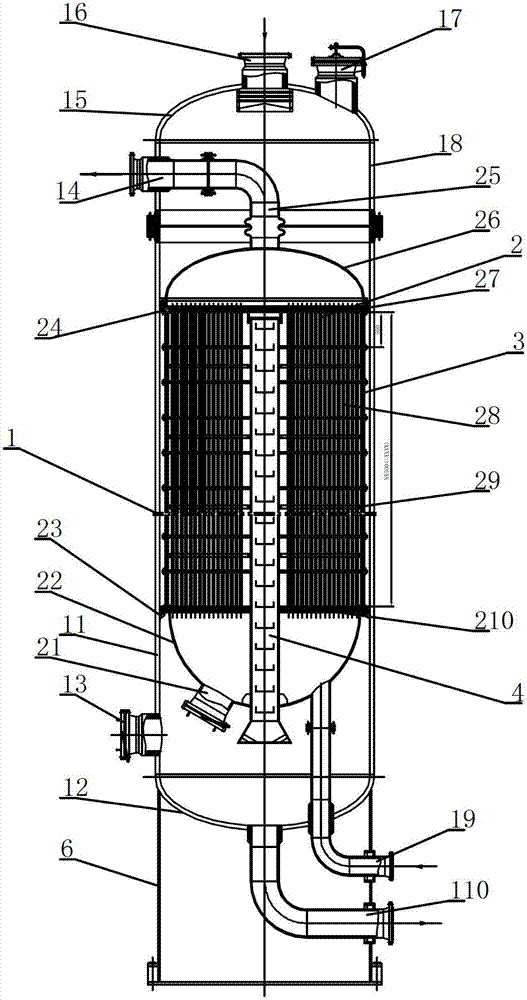

[0040] Figure 1 to Image 6 As shown, the CO omni-radial isothermal shift furnace includes:

[0041] The furnace body 1 includes a main body 11, an upper head 15 and a lower head 12, a transition section 18 is provided between the main body 11 and the upper head 15, and a flange is detachably connected between the main body 11 and the transition section 18. The main body 11 It is welded with the lower head 12, the upper head 15 and the transition section 18. The top of the upper head 15 is provided with a reaction gas inlet 16 and an upper maintenance manhole 17, a circulating cooling water outlet 14 is provided on the side wall of the transition section 18, a lower maintenance manhole 13 is provided on the side wall of the lower end of the main body 11, and a lower maintenance manhole 13 is provided at the bottom of the lower head. There is a cooling water inlet 19 and a shift gas outlet 110. The bottom of the furnace body 1 is seated on the skirt 6, which is the supporting ...

Embodiment 2

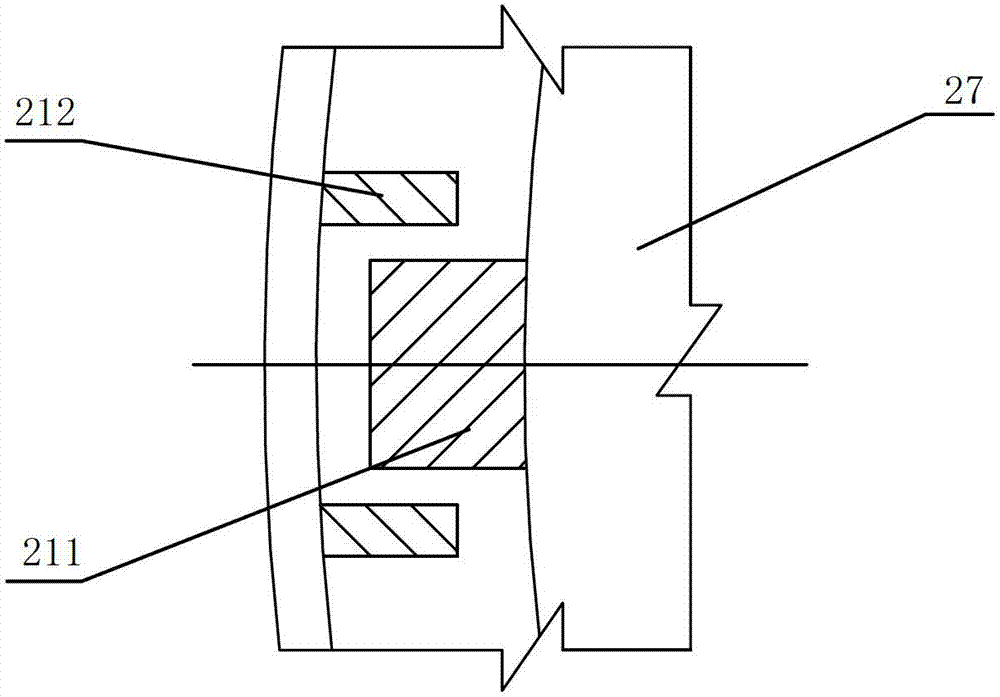

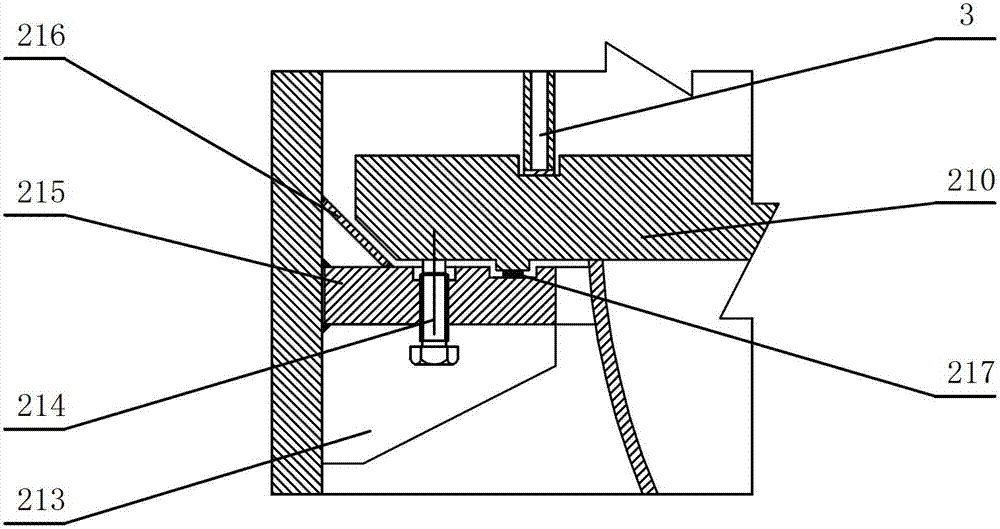

[0046] Such as Figure 7 , Figure 8 As shown: the gas distributor in the CO omni-radial isothermal shift furnace is composed of several distributors with the same structure bolted together, each distributor includes an inner cylinder 55 and an outer cylinder 54, and the inner cylinder 55 consists of a triangular shape with a length of 500mm The ribs are arranged in gaps. The outer cylinder 54 is composed of two semicircular cylinders. Two sets of vertical connecting plates 53 are welded at both ends of the semicircular outer cylinder to bolt the semicircular cylinders together to form a cylindrical cylinder. The outer cylinder 54 is uniformly distributed with round holes, and the inner cylinder 55 is used as a gas secondary distributor. The gap between the triangular ribs is smaller than the diameter of the outer cylinder and not greater than 3mm. At the same time, the contact between the outer cylinder and the upper tube plate 27 is kept at a height of 100mm without opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com