Independent weight adding force standard machine and independent weight adding method

A standard machine and weight technology, applied in the calibration/testing of force/torque/power measuring instruments, weighing equipment testing/calibration, measuring devices, etc., can solve problems such as large reverse loads, and achieve fast loading and unloading, control The method and process are simple, and the effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

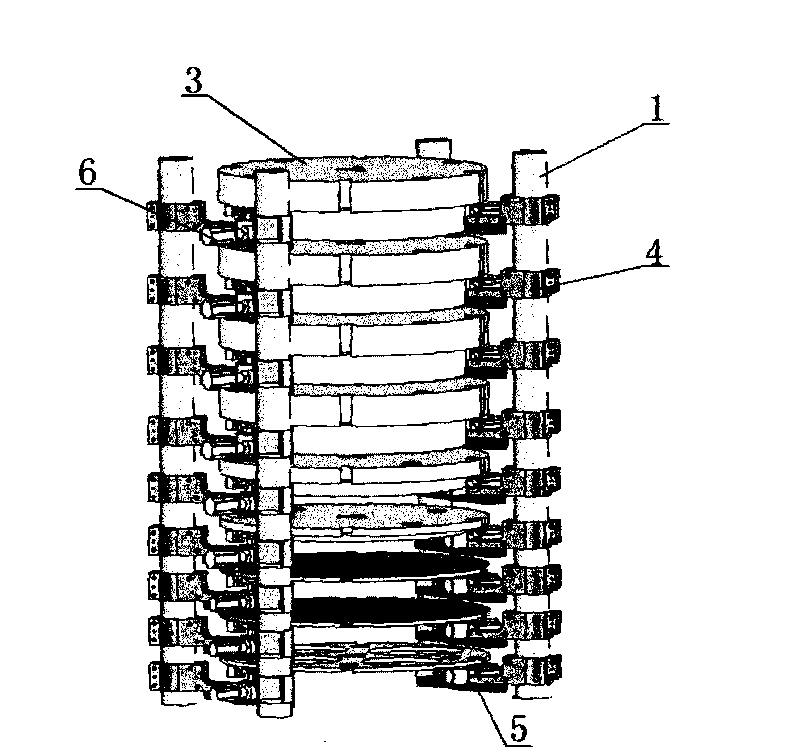

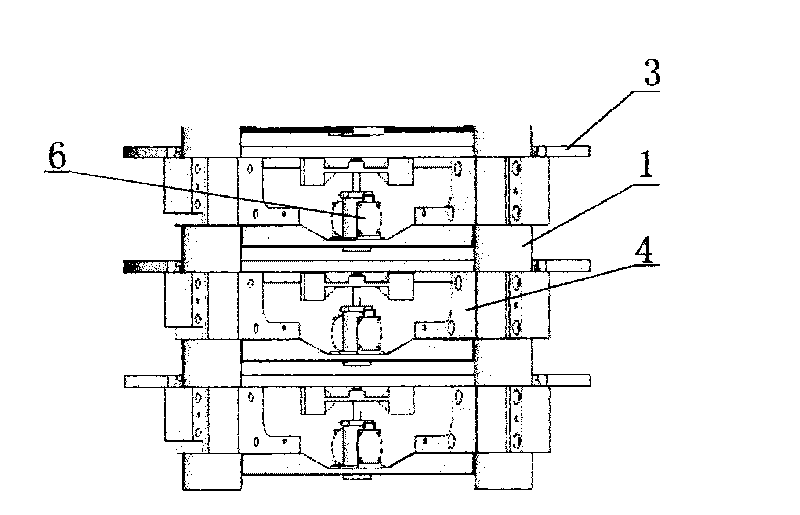

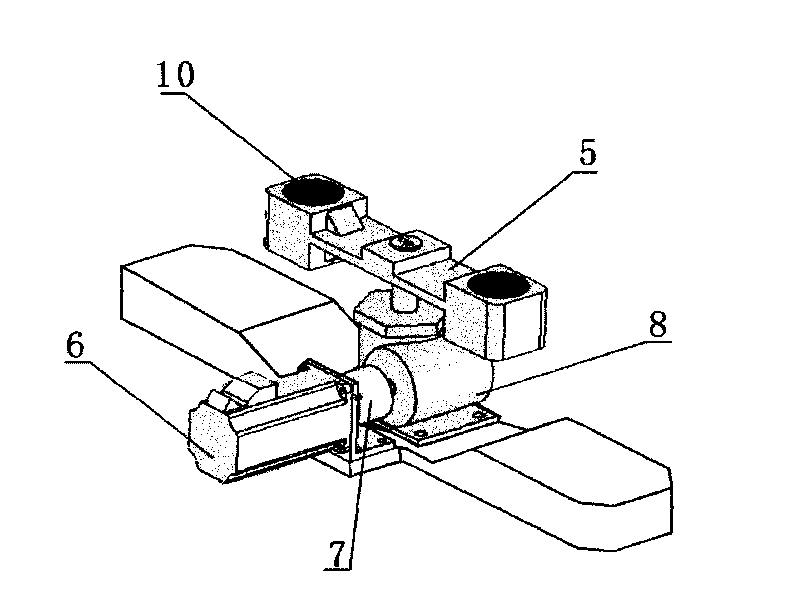

[0018] The force standard machine with independent weighting includes the main frame 1 and the weight hanging 2. The main frame 1 is equipped with 9 weights 3 and 9 sets of motion mechanisms arranged vertically in layers. Each set of motion mechanisms includes two pairs of supports. Corner 4, a pair of brackets 5, a pair of servo motors 6, a pair of reducers 7, a pair of worm gear pairs 8; A pair of force sensors 10 are arranged on each bracket 5, and a weight 3 is placed on each pair of brackets 5. Such as Figure 1-4 .

[0019] The masses of the nine weights 3 are combined in multiples of 1, 1, 2, 5, 10, 20, 20, 20, and 20; the mass of the weight hanging 2 is twice that of the multiple of 1.

[0020] Bracket 5 is a ball screw bracket.

[0021] Taking the 100kN force standard machine as the embodiment of the present invention, the 9 static weights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com