High-elasticity graphene composite deformation sensing material and preparation and application method thereof

A technology for graphene composite and sensing materials, which is applied in the field of highly elastic graphene composite deformation sensing materials and their preparation, and achieves the effect of simple and efficient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of graphene oxide:

[0036] Pre-oxidize 10g flake graphite with 100ml concentrated sulfuric acid, 8g potassium persulfate and 8g phosphorus pentoxide (80°C, 4 hours), centrifuge, wash (wash to neutral with deionized water), dry (50°C under vacuum 12 hours) to obtain pre-oxidized graphite; 4g pre-oxidized graphite, 4g sodium nitrate and 104ml sulfuric acid were stirred in an ice bath, then 21g potassium permanganate was added in three batches, reacted for 4h, moved to a 40°C water bath for 40min, and then Add 600ml of deionized water, raise the temperature to 95°C and keep it warm for 10 minutes, then add excess hydrogen peroxide until no bubbles are generated, let it stand still, pour off the supernatant, add water to the lower layer and centrifugally wash until neutral, dry at 40°C for 12 hours, and obtain graphene oxide .

Embodiment 1

[0038] (1) Ultrasonic dispersion of graphene oxide in deionized water (ultrasonic power is 100W, ultrasonic 2 hours), to obtain a graphene oxide aqueous solution with a concentration of 5mg / ml;

[0039] (2) Add carboxymethyl cellulose sodium powder to the graphene oxide aqueous solution prepared in step (1), and stir together for 2 hours under 40°C water bath conditions (the stirring speed is 400 rpm), wherein graphene oxide and carboxylate The mass ratio of sodium methylcellulose is 20:1, and then stand for 12 hours to fully cross-link the mixed solution, form ice at -40°C, and then vacuum freeze-dry (-40°C, 20Pa) for 60 hours to obtain graphene oxide / fiber Plain airgel;

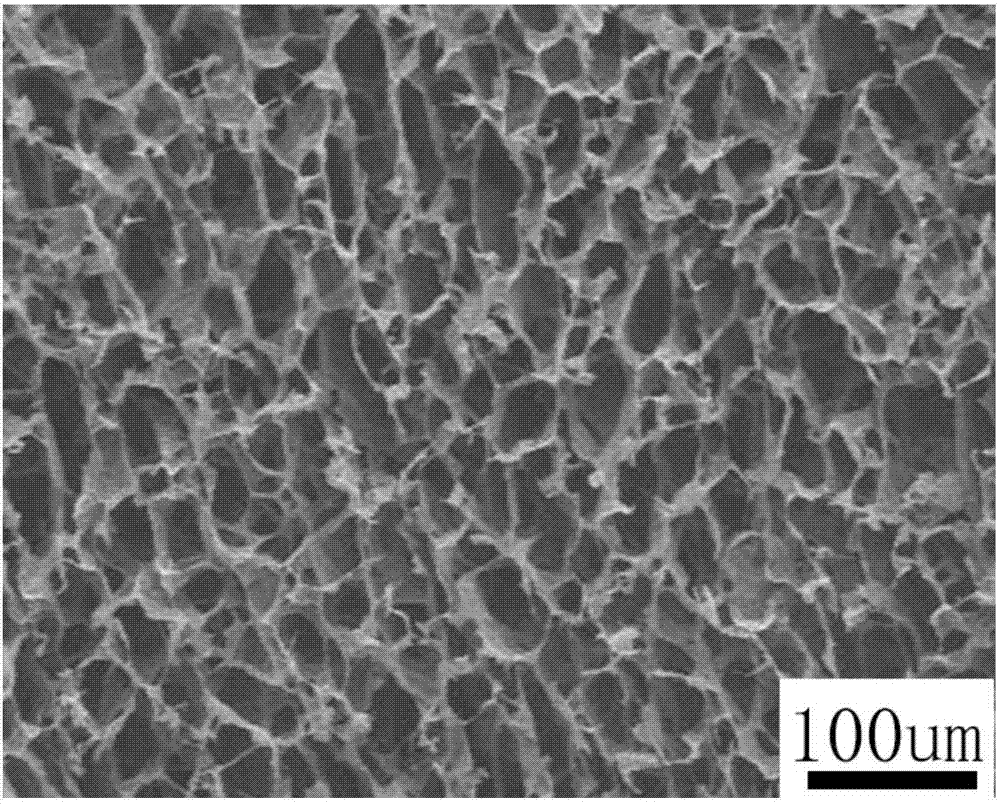

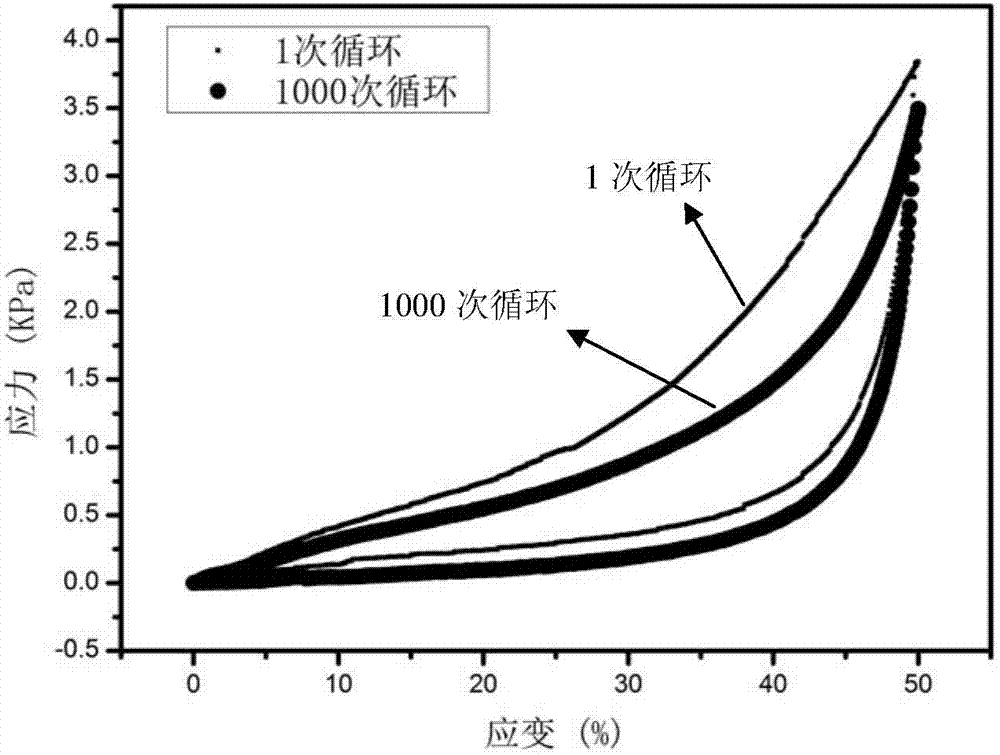

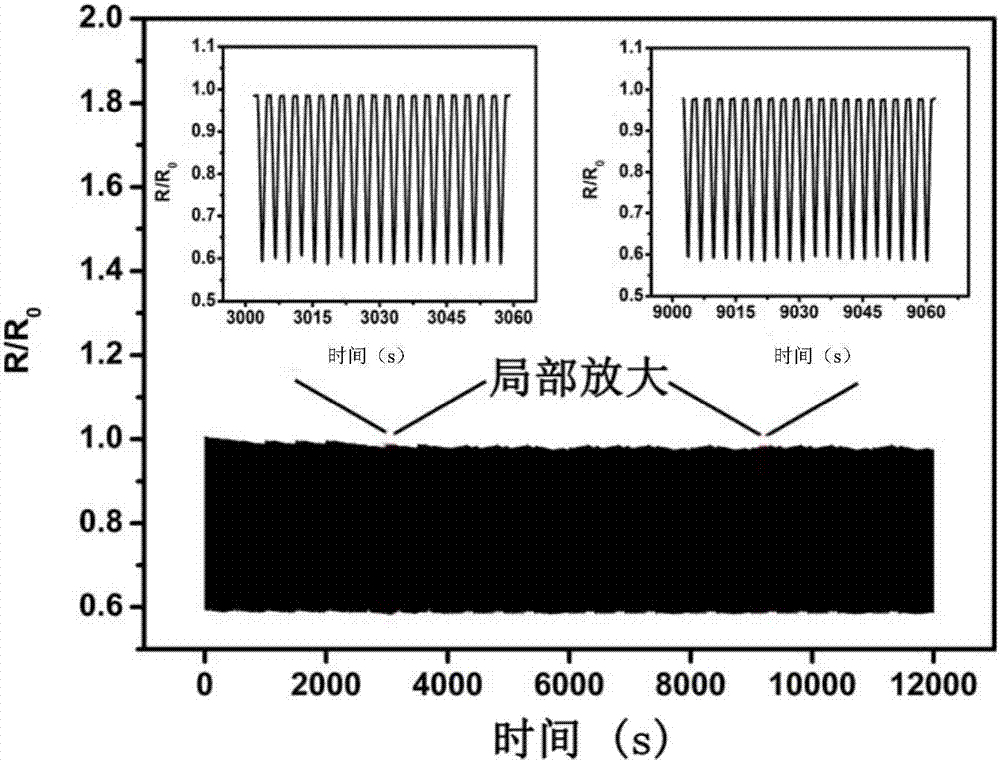

[0040] (3) Gas-phase reduction of graphene oxide / cellulose airgel with hydrazine hydrate (reduction temperature is 80°C, reduction time is 3h, hydrazine hydrate steam-reduces airgel in a reactor), and dried at 120°C for 12 hours to obtain Highly elastic graphene composite deformation sensing material RGO / C...

Embodiment 2

[0042] (1) Ultrasonic dispersion of graphene oxide in deionized water (ultrasonic power is 100W, ultrasonic 2 hours), to obtain a graphene oxide aqueous solution with a concentration of 5mg / ml;

[0043] (2) Add carboxymethylcellulose sodium powder into the graphene oxide aqueous solution prepared in step (1) and stir together for 2 hours under 40°C water bath conditions (the stirring speed is 400 rpm), wherein graphene oxide and carboxymethyl The mass ratio of base cellulose sodium is 10:1, and then let stand for 12 hours to fully cross-link the mixed solution, form ice at -40°C, and then vacuum freeze-dry (-40°C, 20Pa) for 60 hours to obtain graphene oxide / cellulose Aerogel;

[0044] (3) Gas-phase reduction of graphene oxide / cellulose airgel with hydrazine hydrate (reduction temperature is 80°C, reduction time is 3h, hydrazine hydrate steam-reduces airgel in a reactor), and dried at 120°C for 12 hours to obtain Highly elastic graphene composite deformation sensing material R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com