Method of laser digital coloured drawing

A painting and digital technology, applied in the field of optically variable graphics, can solve the problems of service life, high price of laser color printing, etc., and achieve the effect of strong flexibility, flexible graphic design and painting, and high positioning accuracy of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: a kind of method of digital laser plane color painting, comprises the following steps:

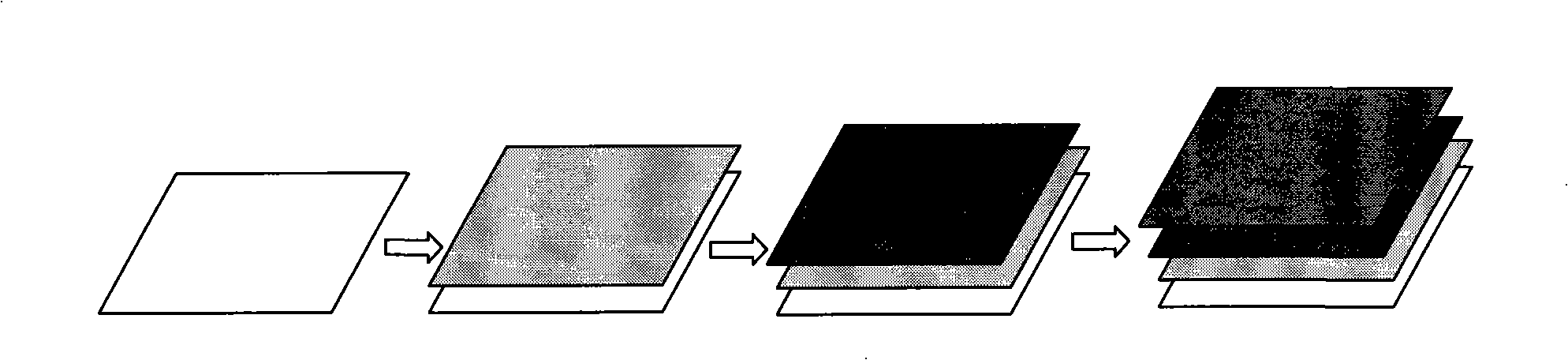

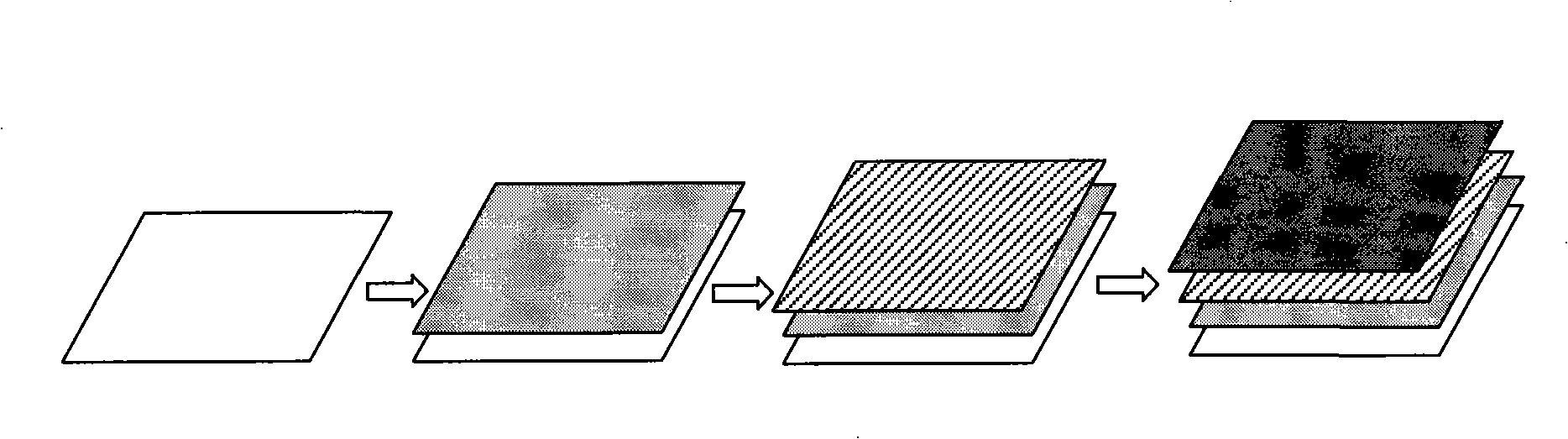

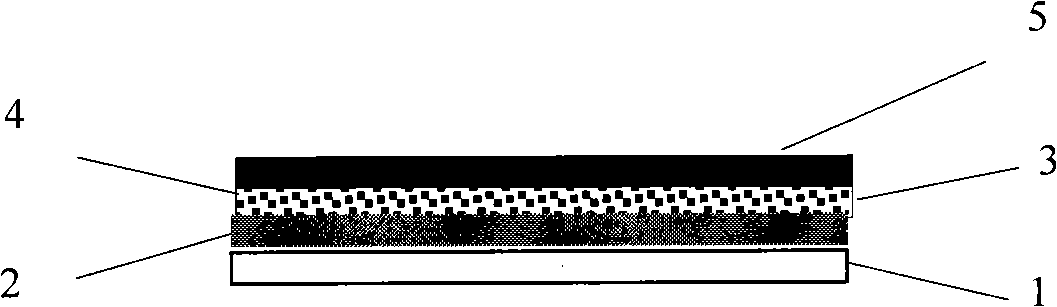

[0040] (1) See attached Figures 1 to 3 As shown, a multi-layer film structure with an information layer, the information layer in the film structure can be black resin, or a resin impregnated with C, M, Y (or R, G, B) tricolor dyes ( figure 1 ), or the light-varying graphic information of the relief phase structure with a reflective layer ( figure 2 ), and finally made to coat the release layer, information layer, and adhesive layer from the inside to the outside of the substrate layer, thereby forming an attached image 3 The multi-layer film structure shown is the required thermal transfer film;

[0041] (2) The multi-layer film structure is closely attached to a hard material, and the pulsed laser beam is shaped into a uniform square or circular spot through the optical path to irradiate the covered film, so that the film is instantly heated at the position o...

Embodiment 2

[0043] Embodiment two: a kind of method of digital laser plane painting, comprises the following steps:

[0044] (1) prepare a kind of multi-layer thin film structure with information layer, in this thin film structure, information layer can be black resin, or be infiltrated with C, M, Y (or R, G, B) tricolor dye For the optically variable graphic information of resin or relief phase structure, the release layer, information layer, and adhesive layer are respectively coated on the substrate layer from the inside to the outside, thus forming a multi-layer film structure;

[0045] (2) The multi-layer thin film structure is closely attached to a hard material, and the pulsed laser beam is shaped into a uniform square or circular spot through the optical path to irradiate the film, so that the instantaneous heating temperature of the film at the position of the spot area reaches 120-150 degrees, so that the information layer in the film is separated from the base layer and adsorbe...

Embodiment 3

[0047] Embodiment three: a kind of method of digital laser roller painting, comprises the following steps:

[0048] (1) prepare a kind of multi-layer thin film structure with information layer, in this thin film structure, information layer can be black resin, or be infiltrated with C, M, Y (or R, G, B) tricolor dye Optically variable graphic information of resin or embossed phase structure, the final effect is made by coating the release layer, information layer, and adhesive layer from the inside to the outside of the substrate layer, thereby forming a multi-layer film structure;

[0049] (2) The multi-layer thin film structure is closely attached to a flexible material, and the pulsed laser beam is shaped into a uniform square or circular spot through the optical path to irradiate the film, so that the instantaneous heating temperature of the film at the position of the spot area reaches 120-150 degrees, so that the information layer in the film is separated from the base l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com