Toughening and reinforcing paintable reclaimed ABS (Acrylonitrile-Butadiene-Styrene) and preparation method thereof

A paintability and toughening technology, applied in the field of toughening and enhancing paintability recycled ABS and its preparation, can solve the problems of reducing the surface polarity of recycled ABS resin, not mentioning the surface of recycled ABS, difficult to paint, etc. The effect of excellent mechanical properties and paintability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

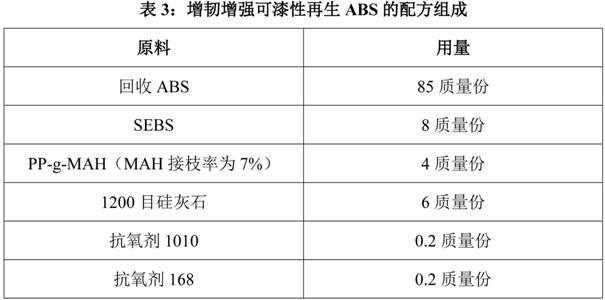

Image

Examples

preparation example Construction

[0017] A method for preparing toughened and enhanced paintability regenerated ABS, comprising the following steps: uniformly mixing the above-mentioned various materials, and then melting and extruding at 190-220°C.

[0018] The toughening agent is at least one of ABS high rubber powder, EVA, SEBS, SBS, and EPDM. The compatibilizer is maleic anhydride grafted polyolefin. The maleic anhydride grafted polyolefin is one of PP-g-MAH and PE-g-MAH. In the maleic anhydride grafted polyolefin, the grafting ratio of maleic anhydride is ≥5%. The filler includes calcium carbonate, talcum powder, wollastonite, barium sulfate and kaolin. The antioxidant is at least one of hindered phenol antioxidants and phosphite antioxidants.

Embodiment 1

[0021] A kind of toughened and strengthened regenerated ABS with paintability, its formula is composed as following table 1:

[0022]

Embodiment 2

[0024] A kind of toughened and strengthened paintable regenerative ABS, its formulation composition is as follows table 2:

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com