Automatic elevator guide rail painting line

A technology for elevator guide rails and paint lines, which is applied to spraying devices, coatings, and devices for coating liquid on the surface, etc., which can solve the problems of large influence on the quality of T-shaped guide rail painting, heavy labor workload, and uneven paint thickness and other problems, to achieve the effect of good painting effect, high painting efficiency, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

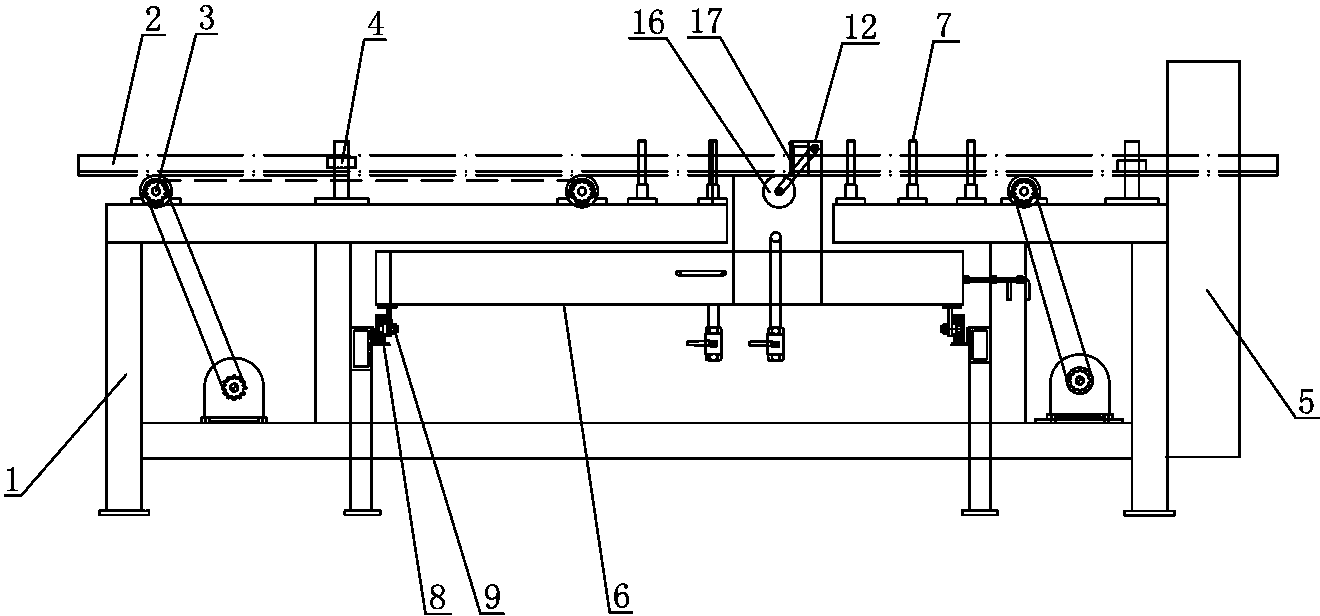

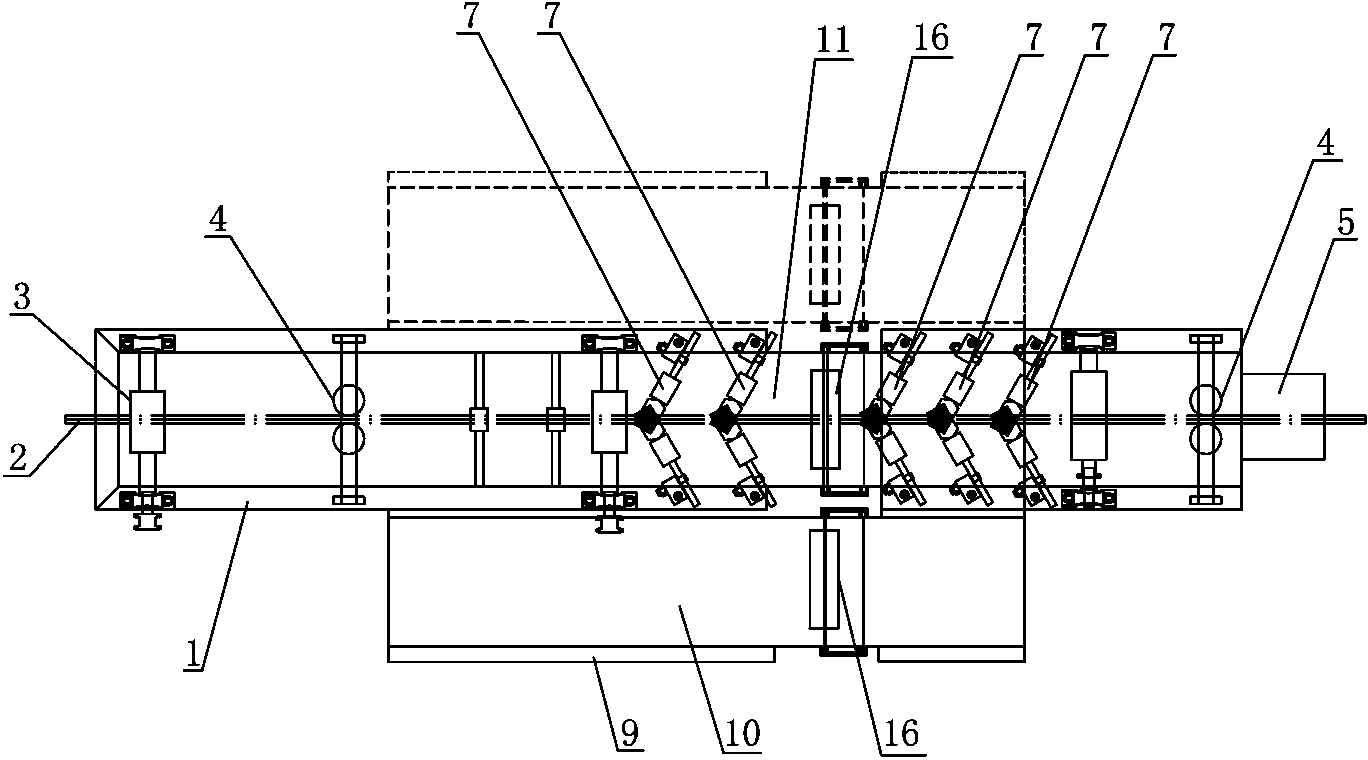

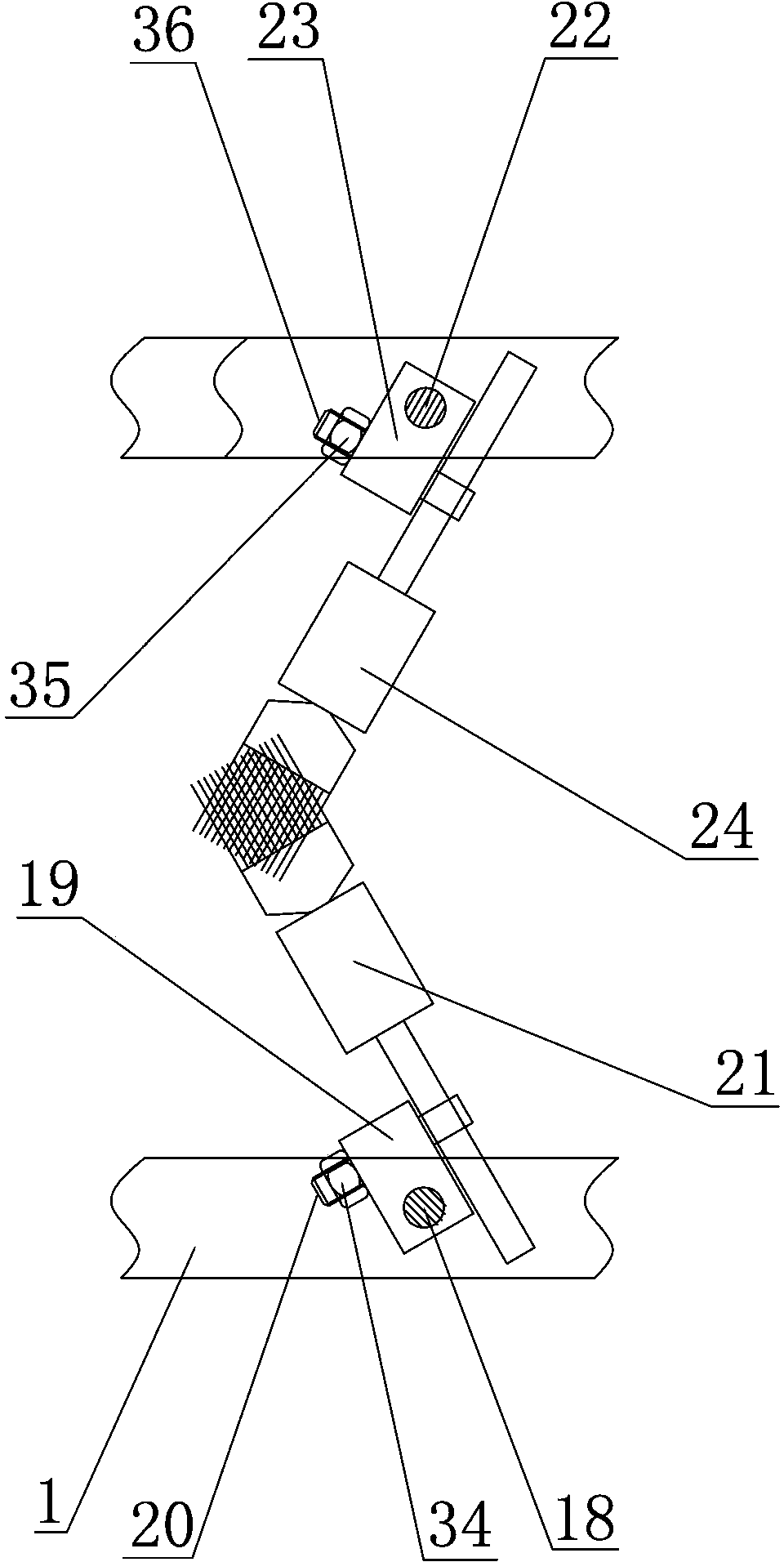

[0016] like figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the described elevator guide rail automatic paint line comprises: a frame 1, in the frame 1, a plurality of conveying rollers 3 for horizontally and horizontally carrying the elevator guide rails 2 placed in a ⊥ shape and guiding the elevator guide rails are arranged at intervals 3. The centering guide mechanism 4 for centering and conveying, in the frame 1 along the conveying direction of the elevator guide rail 2, a paint spraying mechanism 5 and a paint brushing device are sequentially arranged at intervals, and the paint spraying mechanism 5 can spray paint to the guide arm of the elevator guide rail. The connecting part, the paint brushing device comprises a bottom surface paint rolling mechanism 6 arranged in the frame along the conveying direction of the elevator guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com